- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

The Future of Digital Manufacturing

Standardizing tool data description reduces programming time, improves efficiency

- By Swapnil Gupta and Wesley Tonks

- June 7, 2016

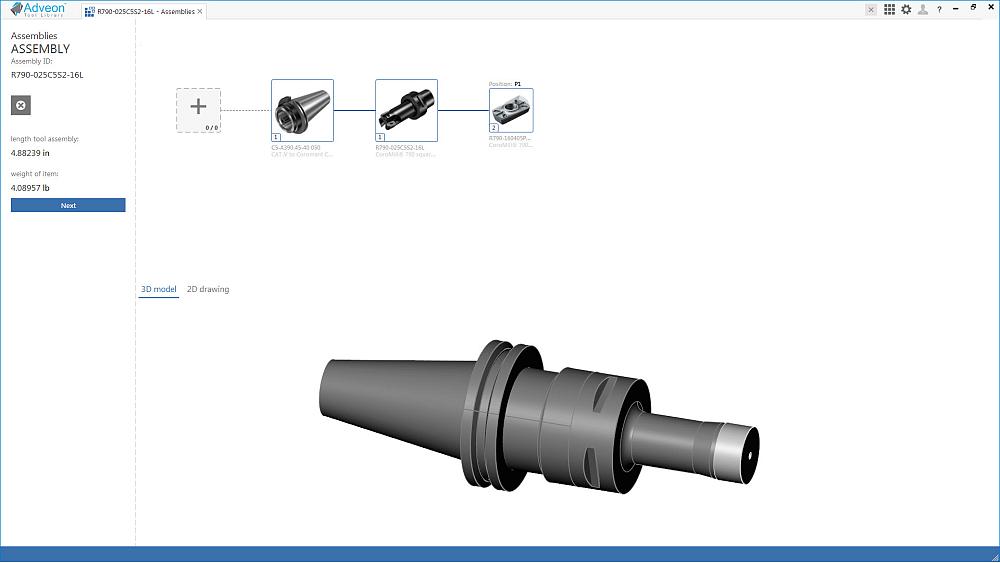

Adveon is a tool library with an open platform system on which any cutting tool supplier can load its ISO 13399-compliant catalogs.

Manufacturers are tasked with increasing productivity and improving security in every aspect of the production process, without sacrificing quality. Several new integrated options have emerged that will support engineers in their success, ultimately driving digital manufacturing to the next level.

The demand for fully integrated and connected manufacturing systems has never been greater.

However, manufacturers are facing several challenges in an increasingly complex environment. Faster product introductions put pressure on engineers and machinists to decrease the time from design to production, often affecting their ability to keep up with rapid-fire advancements in tooling equipment and components, multitask tools, and other complex tools.

As the machining industry shifts from mass production to a higher degree of customization, companies are increasingly turning to computer aided manufacturing (CAM) to enable more rapid, adaptable, and accurate production via simulated machining.

Virtual Tool Libraries

CAM operators are faced with their own obstacles to productivity and security when using the simulation software. One of their main issues is the need to create content for their virtual tool libraries, a time-consuming process that must be re-created each time they begin a new project. Another problem is the lack of standardization within the different brands of tools, causing unnecessary extra work and diligence to determine the best fit for the project, sometimes with unpredictable results.

Several answers have emerged that, when applied cooperatively, introduce an intelligent, comprehensive, and integrated solution and may serve as the next wave in the future of digital manufacturing.

Standardized Tool Data Descriptions

There are approximately 1.2 million manufacturing units in the world today. Traditionally, all CAM suppliers, machine tool builders, and tool suppliers developed their own methods of denominating and structuring their information about tools. The need for a standard way of communicating tool data was apparent to anyone who has ever had to search for and map cutting tool data to structure a project design.

Enter ISO 13399, a new standard and new globally recognized way of describing tool data.

This international standard sets how a tool’s attributes, such as length, width, and radius, are to be defined, allowing the exchange of data for cutting tools to be consistent regardless of the tool manufacturer or brand. When all tools in the industry share the same parameters and definitions, the communication of tool information between software systems and machines is considerably improved.

Sandvik Coromant and other cutting tool manufacturers have embraced the standard; Sandvik Coromant has been using an ISO 13399-based catalog since 2013.

Tool Data Library

The vast array of cutting tools in today’s market forces CAM operators to search for tool data in disparate catalogs and websites each time they begin a project.

In addition, they have no way of saving their most often used tools in a personal collection or database.

A resolution to this problem was the development of virtual libraries of the tools from major manufacturers. Adveon, one such tool library, is an open platform system on which any cutting tool supplier can load its ISO 13399-compliant catalogs. Initially Sandvik Coromant’s contribution to Adveon included about 12,000 tools within the rotational assortment, and now the company has more than 25,000 tools in the system.

The library is designed so that updates, additions, and corrections can be made easily, instantly providing the most current and relevant data to subscribed users and significantly improving work flow. Plans to add modules for supporting tool recommendations for process optimization are in the works.

“Pressure to reduce time from design to production, combined with the ever-increasing complexity of tools, makes rapid access to accurate and current tool data more critical than ever. Companies can no longer afford to rely on manual data entry, and operators need a single tool library that can manage tools from multiple manufacturers. Adveon has been designed from the ground up to address these challenges,” said Klas Forsström, president of Sandvik Coromant.

Integration of Systems

The availability of a comprehensive library of standardized tool data is a huge step in the race towards the future of digital manufacturing. The next step was to embed the library within CAM software, CNCs, and simulation software, which has taken place in CAM systems like Edgecam.

Once a tool library is integrated into simulation software, the planning and selection of tools and the computer modeling of the manufacturing process become a seamless task. The user searches for components and receives options from the library. Once the user makes appropriate selections, assemblies can be quickly built in 2-D drawings and 3-D models, which can then be exported to simulation software. The entire process drastically reduces time spent on tool selection and tool assembly creation, and it provides simulations with greater precision.

Without a doubt, CAM software integrated with an ISO 13399-compliant tool library improves the consistency and quality of data. A library loaded with standardized information offers engineers the most dependable options and designs. Better data quality means better security and confidence in the process; highly accurate simulation and visualization reduces the likelihood of collisions.

Making this especially critical is the increasing use of harder metals. More than ever before, the density and resistance of the materials require users to determine the optimal toolpath. And for each type of metal, predicting and accounting for the wear pattern of each component are a vital aspect of the production design that the integrated library/CAM can help to provide.

Edgecam, a CAM software developer, is the first supplier to integrate Adveon into its CAM software. The system allows users to create tool assemblies based on projects most often used in their daily work. Users can quickly build their tool assemblies and databases, see immediate results in 2-D and 3-D, and export for CAM programming and simulation – all in one intelligent platform.

And since Adveon uses only ISO 13399-compliant tool information from an array of manufacturers, and tool data is automatically updated via the cloud, users can access the most accurate and up-to-date information each time they open up the library.

“Our job is to go from virtual component to real component as quickly as possible,” said Edgecam General Manager Raf Lobato. “There are two key factors that we strive to resolve: the time taken to produce the NC code, and the time taken on the machine to produce the component.”

According to Lobato, several elements must be combined in order to do this properly. The system must allow the user to replicate the real environment in the virtual environment as closely as possible, which means incorporating aspects such as tooling, fixtures, vises, stock, and machine tools. Also, the system should support the best possible work flow for generating and proving out the NC code, and ensure the NC code for tooling, feeds/speeds, and toolpaths is optimized to reduce machining time.

Because of the more intuitive design of the system, users of software integrated with Adveon will experience a fundamental shift in the way they work. The selection of tools will no longer be deferred to the production phase at the machine shop. It will move forward to the planning and component design phase.

The future of digital manufacturing hinges upon the collaboration and integration of once disparate technologies to develop an increasingly seamless, predictable, and cost-effective process. Because of ingenious advancements in technology and standardization, the outlook of digital options in the tooling industry is optimistic. These include improved work flow, superior quality, better precision, and improved efficiency, all of which ultimately lead to faster product time to market.

Swapnil Gupta is virtual machining specialist, Sandvik Coromant, 800-726-3845, www.sandvik.coromant.com.

Wesley Tonks is strategic partnership manager, Edgecam, 866-334-3226, www.edgecam.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Identifying the hallmarks of a modern CNC

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI