Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Changing the welding skills gap conversation

How employers and educators can work together to better manage the talent crunch

- By Rob Colman

- August 25, 2022

- Article

- Welding

The skills gap discussion has gone on ad nauseam for the more than 20 years I’ve worked in publishing. When I started, it was on its way; it has since arrived. The question of how to manage it—and often how to apportion blame—gets passed around like a hot potato. At the recent FABTECH Canada show, a keynote presentation by the Canadian Welding Bureau Association (CWBA) Director Max Ceron and a panel discussion hosted in conjunction with the CanWeld Conference about women in the automotive industry highlighted how employers and educators can work to solve the problem proactively.

Create Community Connections

Ceron and Nikki Noble, coordinator and professor of welding, Lambton College, both encouraged business owners to reach out to training centres in their area to create a connection between the needs of industry and what is being taught in schools.

“We tend to think of training centres as places that exist in a bubble,” said Ceron. “We are not getting in there enough to tell them what they need to do well. It’s our responsibility as industry to make our expectations known. That communication is very important.”

“I will purposely adjust our curriculum if I know there are jobs for students when they graduate,” said Noble. “One employer gave us a whole box of material recently and said, ‘Can you fit this into your program?’ We jumped at the opportunity. Now, in September, the course will be adjusted slightly to incorporate what this employer needs using this material. We can make a project out of that.”

Noble tries to connect all her training to a career path.

“Whenever we do a certain process or position, or use certain types of wires, I love to give examples of where they could apply that,” she explained. “So, when we’re in the class I like to say, ‘Today we’re doing this, and actually company XYZ is hiring right now and this is what they do daily.’”

Ceron noted that when students have a chance to practice on old parts or blueprints from a company, they aren’t walking into a completely foreign environment if they get hired later on. “Suddenly it’s not new and strange,” he said. And a new employee can get up to speed sooner.

Of course, this is a two-way street. Ceron encouraged instructors to reach out to local industry as well to determine what processes are most in demand in their shops.

“Educators, don’t be shy,” he said. “Ask employers what they do, how much automation they have, what programs and robots and pendant styles they are using. Most vendors have some version that they can get into your classroom so that your students will be ready for the local industry they’ll be joining.”

Stephanie Hoffman, owner of UnderGround Metal Works, encouraged companies to get involved with college program advisory committees to keep schools apprised of their needs as well. “Give the schools a call and see how you can connect with them,” she encouraged.

Canadian Welding Bureau Association (CWBA) Director Max Ceron addresses the audience at FABTECH Canada.

Similarly, Ceron encouraged businesses to get involved with associations like CWB and the Fabricators & Manufacturers Association International (FMA).

“Going to association meetings really increases the visibility of your company,” he said. “It puts the seed in people’s heads so that when they see a job posting online from your company, they think of you.”

Attract Talent With Facts

Many companies complain that when they advertise a job, they get a lot of applicants, but few have the skills they need. Ceron’s first question to shop owners is: Are you advertising the job properly?

“Are you clearly and fully explaining your needs?” he said. “If you are asking for a general welder, that’s not recruitment.” The more detail you can include in your advertisement in terms of the type of welding that will be required can ensure that people with the right skill sets apply. Ceron encourages employers to involve the welding supervisor in this process to make sure all their needs are met in the job description.

“If you only weld thin-gauge material all day, and you state that, the person who welds pipe all day is not going to apply for your job,” he said. “That’s good because it wouldn’t be a good fit anyway.”

Honesty, he says, is key.

“If you need people to work nights or modified hours, they have to know you have that expectation,” he said. “But if that is clear, there are plenty of welders out there who are fine with that and actually appreciate the opportunity to work those kinds of hours.” Likewise, if the job will require travel, working at heights, or any other specification, it’s important that this be made clear.

Don’t Fear Training

As Ceron pointed out, everyone is looking for that “unicorn” employee—the 23-year-old who knows everything and can work independently from day one. That’s just not likely to happen, so it’s important to keep expectations realistic.

“You are going to have to do some training,” Hoffman concurred. “You don’t need someone with six years of experience, even for some structural steel work, but some training will be necessary on the job. It can be done in very little time if done correctly.”

Noble agreed.

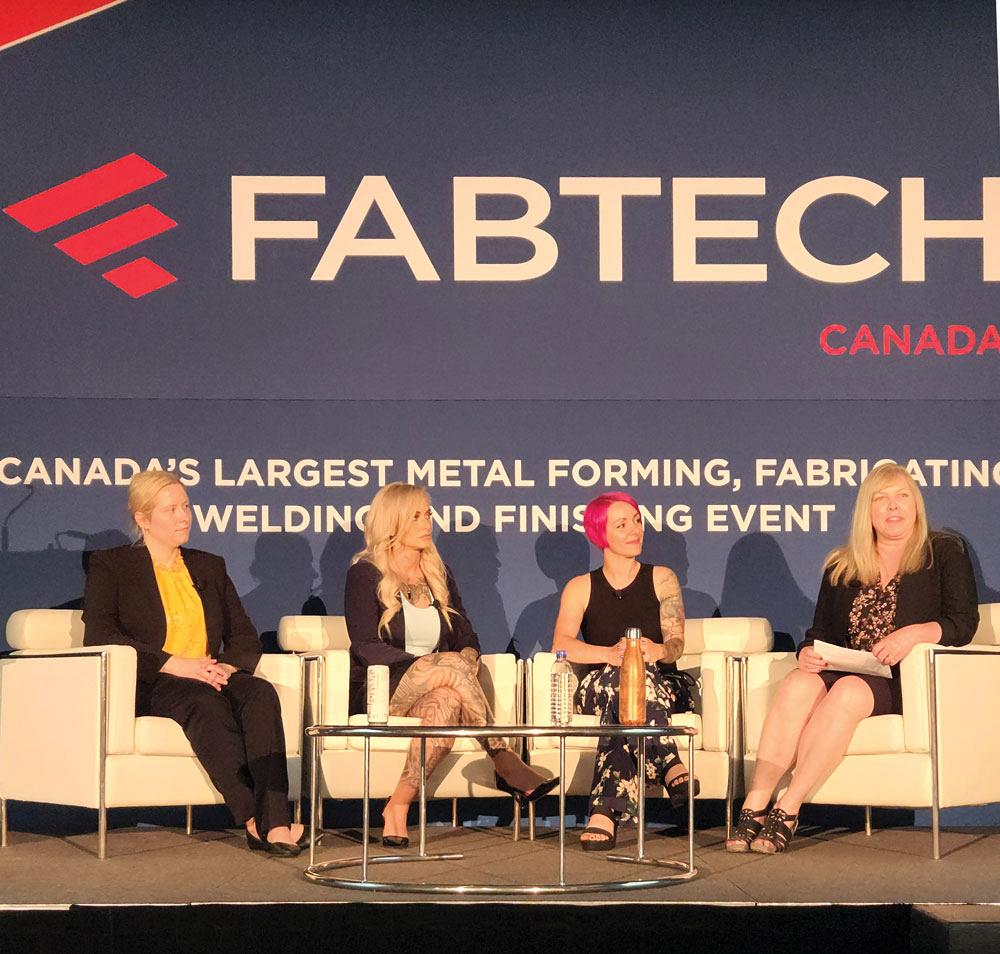

Panellists Taylor Dittrich, Stephanie Hoffman, and Nikki Noble in conversation with moderator Leanne Jeffries, vice-president, Assured Performance Network/Certified Collision Care.

“A fillet weld seems straightforward, but it’s the position you’re in, the size of the material you are working with; many things will affect how comfortable you are with the process,” she said.

As Hoffman pointed out, a student is used to working in very controlled conditions.

“A shop may have a job that doesn’t have a perfect fit-up like you have in a classroom, and these kids don’t have the problem-solving capabilities yet to immediately know what to do with that,” she said.

The key is that every shop is a little different, and expectations in that shop can be unclear unless there is at least some training.

If an employee seems to have potential, Noble suggests that companies hire them on provisionally to see if they might grow with the company and be a good fit.

“I’ve encouraged local companies to hold off on the big sticker price when they hire people on because yes, it might sound great to get $35 an hour, but why don’t you do a probationary period at $25 an hour with bonuses if they do really well,” she said. “In the end, the employee might achieve $35 and hour.” In the meantime, both employee and employer can determine if it’s a good fit.

Clarify Career Paths

Taylor Dittrich, wire products research engineer, The Lincoln Electric Co., stressed the importance of communicating to new hires what different positions they can hope to grow into. It’s also important to ensure that there aren’t barriers to advancement.

Dittrich outlined an example of a supply chain company that was trying to determine why they weren’t getting the qualified candidates they needed to bring women up from the floor into management. They realized that there was one area in that supply chain facility that none of the women worked in because it was a more physical area, and many of the men that worked there were concerned that the women wouldn’t want to.

It wasn’t that the company was actively discouraging women, “They just didn’t think that women would be interested in that position, and they weren’t actively recruiting them,” said Dittrich. “But to be in a supervisory or managerial role at this company, you needed to be familiar with every part of the supply chain warehouse. So, by thinking women wouldn’t want to do this job, they were unintentionally excluding them from promotions and managerial positions. It’s something I encourage companies look at—implicit biases that are limiting growth and movement in the company.”

Ceron encourages companies to develop clear salary bands so that employees know what additional skills can help them advance within the company. Being able to give examples of how people have moved up in the company can be encouraging as well.

“We all have these stories,” he said. “We should make it part of the onboarding process—letting people know that there are opportunities if they get more training, or that if they are willing to travel that there might be other opportunities.”

Ceron noted that not every company wants to be involved in an official apprenticeship program, but creating a company-run training system can encourage growth and keep employees engaged.

“Ad hoc training is very obstructive,” he noted. Having a plan of how to grow employee skills from the inside can help the growth of the company.

Walk the Walk

Manufacturers are competing against so many different industries for talent today, and everything is there to be seen and considered online. The question becomes, what small ways can you stand out in the crowd?

“It gets into generational differences,” said Dittrich. “What are young students valuing from employers? It’s not just money. They want a more holistic view of the workplace—somewhere to believe in, somewhere they like to work, where they like the people and see career paths with a better work-life balance.”

Ceron notes that a company’s community outreach says a lot to some.

“Are you supporting the local Red Cross or the Pride parade?” he said. “What kind of social involvement do you have? We’ve been training our kids to be involved, and then we walk into companies that are not. Some will say, ‘I don’t think I want to work there.’”

How a company manages diversity in the shop can make a difference as well. Is yours a shop that welcomes women? If you don’t have many women working in your shop, are you interested in working to change that? Again, being honest with new hires about new directions you want to take in your hiring can be helpful, whether it be in relation to gender or expanding outreach to minority communities.

Ultimately, it’s all about better communication—what you do as a company, what your goals are, what your expectations are, and how you fit into your community. If you want to attract students from a distance, the speakers encouraged shops to post unique projects or processes they’ve done on social media or their website to demonstrate the nature of the shop’s work. The more potential employees know about the company before they walk through the door, the better the fit will be, even before an interview.

There is a great deal of untapped potential talent out there. This is just a taste of how it’s possible for shops to land and keep more of it.

Editor Robert Colman can be reached at rcolman@canadianfabweld.com.

CWB Association, www.cwbassociation.org

Lambton College, www.lambtoncollege.ca

Lincoln Electric, www.lincolnelectric.com

Underground Metal Works, www.underground-metalworks.com

About the Author

Rob Colman

1154 Warden Avenue

Toronto, M1R 0A1 Canada

905-235-0471

Robert Colman has worked as a writer and editor for more than 25 years, covering the needs of a variety of trades. He has been dedicated to the metalworking industry for the past 13 years, serving as editor for Metalworking Production & Purchasing (MP&P) and, since January 2016, the editor of Canadian Fabricating & Welding. He graduated with a B.A. degree from McGill University and a Master’s degree from UBC.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada