- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

- April 25, 2024

- Product Release

- Welding

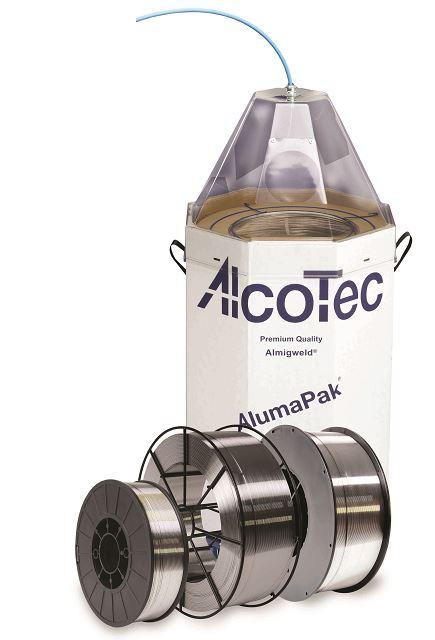

AlcoTec, an ESAB brand, has upgraded all its 4043 and 4047 aluminum MIG welding wire products with a proprietary and patented surface treatment technology. The enhanced AlcoTec 4000 series wires exhibit smoother feeding performance and fewer tangles, according to the company.

The 4000 series aluminum wires are widely used in automotive applications such as electric vehicles (EV) battery trays and bumper assemblies, as well as for bicycles and general fabrication. The MIG wires are available in diameters from 0.030 in. (0.8 mm) to 1/16 in. (1.6 mm), spool sizes of 1, 5, 16 and 20 lbs., and AlumaPak bulk drums of 50, 180 and 311 lbs.

AlcoTec also offers 5000 series aluminum wires manufactured with a patented manufacturing technology that minimizes or eliminates the shaving problem historically associated with these wires. AlcoTec 5356 offers improved wire feedability and arc stability to produce a clean, high quality aluminum welding wire that will not clog gun liners.

ESAB | esab.com

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada