- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

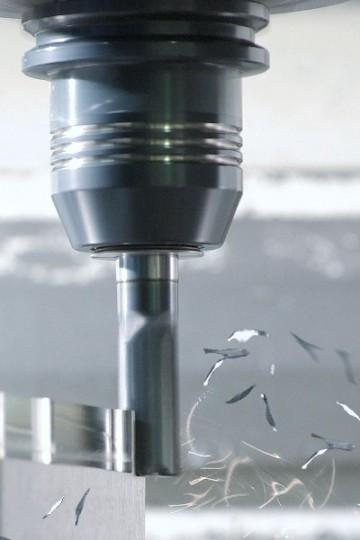

Machine tool, die and mould-making sector on the comeback trail

A resurgent manufacturing sector pumps dollars into machining.

- By Canadian Metalworking

- October 9, 2012

- Article

- Automation and Software

Platinum Tool Technologies of Oldcastle, Ontario is on a roll. The company, which designs, manufactures and repairs industrial moulds, recently invested $2.5 million in new equipment and opened an ancillary facility in Mexico. Estimated 2012 revenues alone for the company’s Canadian plant should “exceed $11 million,” says Platinum Tool president Dan Moynahan. The Mexican operation—which launched May, 2011—might pull in another $2 million.

It’s an impressive track record, given that just a few years ago industry pundits had little but gloom and doom to report in Canada’s machine tool, die and mould (MTDM) sector. The combination of a brutal recession and drastic cutbacks in automotive production devastated the sector, particularly in the industrial heartland of southern Ontario.

While many Windsor-area MTDM shops had to close, “the ones that survived are all doing really well ... I’m busy now,” says Moynahan, who is also a past-president of the Canadian Association of Mouldmakers (CAMM), headquartered in Windsor.

At present, Platinum employs 58 people in Canada and 18 in Mexico.

The MTDM sector hasn’t completely recovered (industrial mould exports are still down) but there is a sense that the economic tsunami is receding.

“With Century, things have been really busy ... manufacturing in Canada is busy again,” says Steve Watson, president of machine tool component distributor Century Tools and Machinery in Mississauga, Ontario.

In particular, automotive production has revved back to life. A total of 2.098 million light-duty vehicles were manufactured in Canada in 2011, according to the Toronto-based Canadian Vehicle Manufacturers’ Association (CVMA). This is a huge leap from 2009, when less than 1.5 million vehicles were built.

“Automotive, as far as mould-makers go, is very strong right now ... it looks like it will remain strong,” states Moynahan

According to Industry Canada, Canadian firms exported $607 million of industrial moulds in 2011. The United States accounted for a majority (some $467.6 million worth) of this total. In 2010, exports stood at $661 million, with $495 million of that going to the U.S.

The jobs return:

Revenues from making tools and dies, meanwhile, are on the rise. Industry Canada lumps tool and die statistics in the category “other metalworking machinery manufacturing”. Exports in this category stood at $712 million in 2011, of which $520 million worth went to the U.S. This is an increase from 2010 when total exports came to $680 million, with $490 million purchased by our southern neighbour.

While overall figures for mould exports are still shaky, some mould manufacturers have fared extremely well. In an annual list, published most recently on October 24, 2011, Plastics News magazine ranked the “Top Mold Makers” in North America. Rankings were based on “North American sales of products in the most recent fiscal year at the time of publication”. Canadian firms dominated the list, occupying first, second and third place. Number one on the list was Husky Injection Molding systems from Bolton, Ontario, with estimated sales of $113 million. This was followed by Concours Mold in Lakeshore, Ontario with $60 million in sales and Active Burgess Mould and Design in Windsor with an estimated $58.8 million in sales. Canadian companies also took the seventh, ninth and tenth spot, giving Canada six entries in the top ten.

One of the biggest developments impacting the MTDM sector is the phenomenon of “reshoring”—that is, Canadian and American firms pulling “offshore” manufacturing operations out of nations such as China.

“A lot of companies that were dealing with the off-shore situation found their intellectual property was not protected ... [offshore operators] would build two moulds, one for the customer and one for the black market,” says Mike Hicks, vice-president at CAMM and vice-president at DMS, an Oldcastle, Ontario firm that licenses the manufacturing and distribution of injection moulding and die-casting components and other products.

Add to this the high-cost of shipping tools and moulds made in Asia and growing wage demands from the locals and it’s clear to see why reshoring would be an attractive option. Having been burned in Asia, some firms are eyeing Mexico as a potential base of operations.

Destination, Mexico:

American, Canadian and European companies are “opening more auto plants in Mexico ... they’re looking to Mexico as their low-cost country as opposed to China ... these plants serve all of South America, North America and some European markets,” says Moynahan.

When it came to setting up his own foreign branch, Moynahan skipped Asia altogether and went directly to Mexico. Things are going so well at his Mexican plant, he’s signed papers to lease a larger facility. The new locale offers 20,000 square feet of manufacturing space and a 30-tonne crane capability, versus a 10-tonne capability at Platinum’s current place of business in Mexico.

The Mexican outpost primarily repairs and maintains moulds from other companies. It also builds components, including a small number of industrial moulds.

“We are there to support existing customers and establish new customers,” explains Moynahan.

In other international developments, the Canadian dollar has been near par with the U.S. dollar for the past year—cause for concern in some quarters.

“Considering that we are currently exporting three-quarters of our work to the U.S., this has been a major problem. Canadians no longer have the upper hand with exchange rates with our U.S. customers,” says Adriano Oppio, vice-president of Classic Tool and Die in Oldcastle, Ontario.

A dollar at par “makes manufacturing less competitive against companies in the U.S., which is a struggle ...the consensus is that [a Canadian dollar around] 80 – 85 cents would be good,” adds Watson.

Strength in dollars:

If an overly strong dollar is worrisome, industry pundits unanimously applaud the Canadian government’s decision to extend the Accelerated Capital Cost Allowance (ACCA) in last year’s federal budget. Originally introduced in 2007 as a temporary measure, the ACCA allows shop owners to write off the cost of new machinery and equipment purchases over a period of three years.

This is quite an improvement over the previous system: “Under the traditional model of depreciation (30 percent declining balance), it takes 14 years to depreciate 99 percent of capital expenditures. By contrast, the ACCA allows businesses ... to deduct almost 42 cents more per dollar invested. This provides an additional return on capital of approximately 12 – 15 percent,” reads a report from the Ottawa-based Canadian Manufacturers and Exporters (CME).

In part because of lobbying from manufacturing associations, Ottawa has agreed to preserve the ACCA at least until 2013.

This is good news, obviously, for MTDM firms thinking about buying new equipment.

Over the past year-and-a-half, for example, Platinum has purchased a five axis gun drill/boring mill from Italian manufacturer Isma, a five-axis high speed machine from another Italian manufacturer called Promac, and palletizers. The company’s palletization system comes from yet another Italian manufacturer, called FCS.

According to Moynahan, many Windsor-area shops are going the palletization route, for the sake of efficiency and productivity. Palletizers have boosted profits at Platinum Tools by three percent, he estimates.

Calling all youth:

Five-axis machining is also catching on.

“We have two trends going at our shop—standardizing controls [with Haas equipment] and five-axis machining. In about a year, I suspect our mills will be five-axis and all our mill and lathe controls will be Haas,” says Rob Muru, president of A-Line Precision Tool in Toronto, Ontario.

Now that the MTDM sector has revived, industry experts have returned to a perennial complaint: the lack of young people entering skilled trades.

“The current situation is that we cannot find skilled workers for our industry. We have been advertising for CNC operators and skilled tool and die makers in all of Michigan and Ontario and are currently even looking abroad for skilled labourers. I see this as being a major downfall for our industry today,” says Oppio.

“We need to bring the youth back into trades ... the industry is facing the same problem that everyone is ... a lot of the skilled people are in the baby boom generation ... for the next ten years, the problem’s going to get worse,” adds Moynahan.

Watson, who chairs the Toronto chapter of the Canadian Tooling and Machining Association (CTMA), remains positive about the future, if wary.

“I’m optimistic about the next few years ... a lot of people are still very cautious though ... they want to know what’s going to happen in Europe, and what’s going to happen in the U.S. presidential elections ... I think the U.S. is going to come back really strong [and Canadian shops will be] competing again against the U.S.,” he states.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada