Chief Technology Officer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Why does digitalization matter to manufacturers?

AI, software development, robotics, and automation will lead manufacturing forward

- By David Alatorre

- October 4, 2023

- Article

- Automation and Software

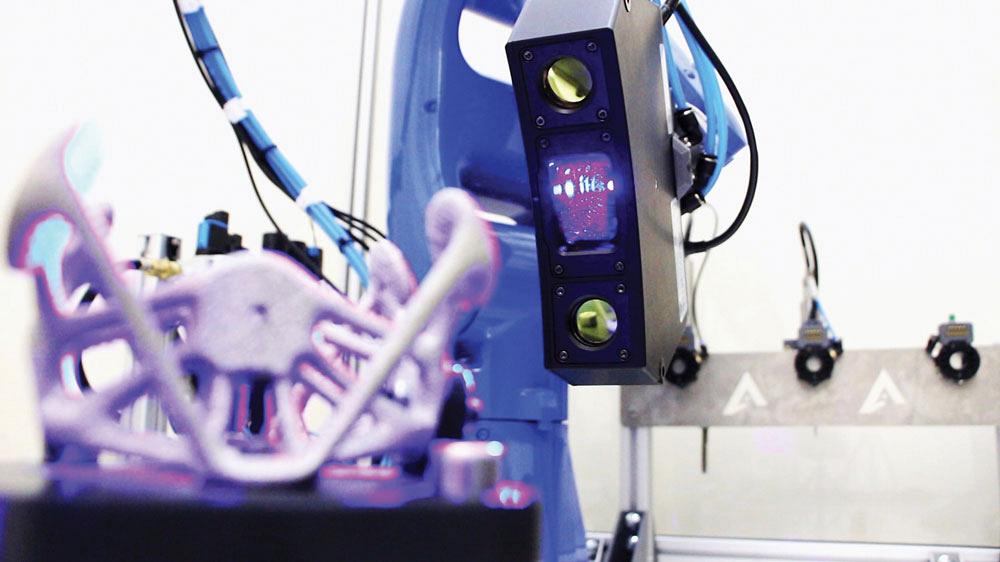

Digitizing craftsmanship requires the use of advanced sensors and algorithms that can adapt when faced with the unexpected.

Finding skilled labour is a challenge being faced by manufacturing organizations across all industries. A societal and cultural shift away from manual, craftsmanship-based roles coupled with the perception of health risks in manufacturing occupations has led to a significant skills shortage in the sector.

Numerous other challenges include regulatory pressures, unstable supply chains, and unprecedented uncertainties, all of which exacerbate the situation and threaten the competitiveness of manufacturing enterprises. The answer to these problems lies within the realm of digitalization and automation technology.

Our analysis is rooted in the evolution of job market trends and the opportunities presented by the digital revolution in manufacturing. By harnessing machine learning, advanced sensors, and proprietary algorithms, the manual post-processing and finishing of metal parts and components turns into repeatable, traceable digital procedures that significantly boost productivity and reduce costs.

A future where the burden of manual labour is alleviated by robotics and artificial intelligence (AI) shows how a “local-for-local” production model—the strategy of manufacturing goods in proximity to their intended customers to promote regional self-sufficiency—can become a reality thanks to digital manufacturing.

Furthermore, new opportunities for work will present themselves in new roles like “digital manufacturing engineer.” This will be appealing to a new generation of computer-literate, technically minded job seekers.

Digital Manufacturing and Labour

Despite recent advancements in industrial safety standards and protocols, manufacturing occupations are still associated with a multitude of health risks such as exposure to harmful substances, repetitive strain injuries, hand-arm vibration syndrome, dust inhalation, hearing loss, vision deterioration, and risks related to machinery accidents, fire, and electrical hazards. It is hypothetically possible to eliminate these risks through comprehensive safety measures; but, even then, trends suggest that this alone will not prevent the looming skills shortage.

In recent years, the allure of traditional skilled workforce sectors such as manufacturing has been diminishing. As pointed out by Mark Muro and other researchers at in their research at Brookings Institution, societal progression and technological development have catalyzed an evolution in the job market, shifting the focus from manual, craftsmanship-based roles to those centred on digital skills and intellectual stimulation.

One of the key factors contributing to this shift is the rapid advancement of technology and digitalization across various industries. The digital revolution has created new and exciting opportunities in fields like AI, data science, software development, robotics, and automation. These professions are attractive because they involve working with cutting-edge, innovative technologies to solve complex problems and push through new boundaries. Organizations of all sizes increasingly rely on digital technologies to enhance their operations, improve efficiency, and gain a competitive edge.

Safety considerations are also a significant factor in career choices, along with physical exertion. As a result, traditional industries like manufacturing and construction are typically associated with being physically demanding and higher risk. For younger people entering the workforce, manufacturing jobs are less likely to attract them for those reasons. This is supported by a survey conducted by Deloitte, which found that millennials and Gen Z workers prioritize purpose and meaning in their careers and avoid higher-risk industries.

As a consequence across the global workforce, but particularly in western cultures, millions of physical and skilled positions remain unfilled, not necessarily due to salary constraints or flawed policies, but because of a pronounced shift towards more fulfilling and safe professions.

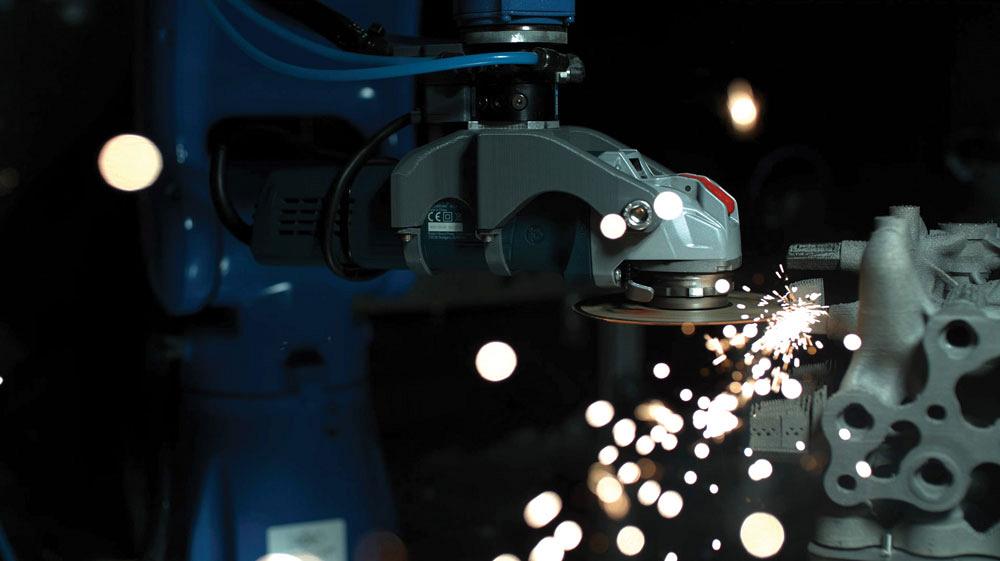

Rivelin is leveraging robotics and AI to unlock a local-for-local production model in metal near-net-shape manufacturing.

Re-industrializing Western Economies

This skills shortage is only one among a growing list of factors escalating manufacturing costs. The manufacturing sector is grappling with a multitude of other challenges, such as unstable supply chains shaken by global events, regulatory pressures tightening the requirements for quality and traceability, and unprecedented uncertainties. The combination of these factors leads to spiralling costs, threatening the competitiveness of manufacturing enterprises.

Supply Chain Susceptibility to Shocks. More than any event in recent history, the COVID-19 global pandemic crystallized how vulnerable global supply chains actually are.

During the height of the pandemic years, manufacturing companies struggled with disruptions across their supply chains and sourcing essential goods and components. Almost every industrial manufacturer had some form of negative effect. Western economies found themselves heavily reliant on distant suppliers who also were in chaos caused by lockdowns, workers in isolation, and reduced transportation/shipping capacity.

This has led directly to companies looking to reduce supply chain risks by reshoring certain industries in the west.

Furthermore, extraordinary events such as the blockage of the Suez Canal in March 2021 also demonstrate the potential fragility of global trade routes. Individually and together, these events serve as indicators for manufacturing companies to diversify–and shorten—their supply chains, promote national and regional production, and mitigate the risks associated with relying on a single transportation route or region.

Geopolitical Factors. Geopolitical tensions are nothing new, and neither is their effect on global trade. The world is currently grappling with the fallout from conflict in Ukraine following the Russian invasion, which has had a considerable impact on the economic landscape, particularly in terms of energy supply.

Western economies seeking to reduce dependency on foreign powers for such critical resources and industries may prioritize re-industrialization efforts to enhance self-sufficiency and reduce vulnerabilities to potential disruptions. As President Biden put it at the recent G7 summit in Hiroshima, countries should “push to build a more resilient and inclusive global economy that can better withstand the kinds of shocks that we’ve experienced over the last few years, including by building a more secure and more diversified supply chain.”

Countries are looking at ways to invest in domestic industries to regain economic strength, to maintain a competitive edge, to protect national security, and to advance technological leadership.

Government Policy Priorities. A strong industrial base is one way that governments can look to establish resilience in the face of potential risks. This can include prioritizing policies that support the revitalization of key industries such as defence, energy, telecommunications, and critical infrastructure. This can also stimulate job creation and economic growth by supporting domestic production and innovation.

The recent signing of the CHIPS and Science Act of 2022 in the U.S. is one example of targeted reshoring policy, and the president’s statements in Hiroshima about “protecting a narrow set of advanced technologies critical for national security” further reinforces this pattern. The European Union is also showing interest in sector-specific policies to promote reshoring, both indirectly, such as through carbon taxes and public procurement rules, and directly, such as through stockpiling mandates and trade/tariff policy. As more governments experiment with sector-specific reshoring initiatives, consensus will gradually form on how to effectively drive re-industrialization.

Automation and digital manufacturing technologies, such as Rivelin NetShape can help manufacturers address their digitalization needs.

Some potential solutions to these challenges lie in the technological advancements of the last decade, particularly in automation technology. The convergence of advanced software tools, AI, and robotics offers a promising path towards re-industrialization. As the experienced workforce edges towards retirement and the global west steers away from inexpensive foreign labour, manufacturing enterprises are turning to the digital paradigm; a world where humans shape ideas, and technology crafts them into reality.

Manufacturing Digital Revolution

Rivelin’s focus is on delivering a sustainable manufacturing future for businesses, their people, and the planet. Digital innovation and progress is not a threat to manual jobs in manufacturing; it offers a new paradigm, one focused on humans shaping ideas and technology crafting them—safely, efficiently, and sustainably.

New processing technology and automation platforms are instrumental in unlocking sustainable “local-for-local” production around the world. This paradigm involves creating localized digital production ecosystems powered by automation technology where products are manufactured near the locations where they will be consumed.

Advanced manufacturing technologies enable this shift for industries like aerospace, defence, energy, and medical, where part complexity, small batch sizes, and skills requirements drove manufacturing overseas to begin with. By focusing on local production, companies can increase efficiency, responsiveness, and resilience while cutting costs, reducing emissions, and supporting regional economies.

There are critical issues plaguing the manufacturing sector, ranging from a significant skills shortage to unstable supply chains, regulatory pressures, and unprecedented uncertainties. The situation necessitates urgent innovative solutions to maintain the competitiveness of manufacturing enterprises.

Automation and digital manufacturing technologies can help address these issues. By capitalizing on machine learning, advanced sensors, and proprietary algorithms, these digital platforms transform skilled manual tasks into repeatable, efficient, and safer digital procedures. This not only boosts productivity and reduces costs, but it also makes the manufacturing sector more appealing to a digitally oriented, safety-conscious workforce.

The unfolding digital revolution in manufacturing is creating a future where robotics and AI can significantly alleviate the demands of manual labour. It enables the transition to a “local-for-local” production model, promoting regional self-sufficiency and reducing supply chain vulnerabilities. The digitalization of the manufacturing industry has profound implications, particularly in re-industrializing western economies, enhancing resilience, and diversifying supply chains.

As societal, technological, and economic dynamics continue to evolve, embracing digitalization and automation technology in manufacturing emerges as an effective strategy to navigate and mitigate the challenges confronting the sector.

It lays a sustainable foundation for the industry, marrying human creativity with technological precision to ensure a safer, efficient, and productive future for manufacturing. The journey from manual craftsmanship to digital procedures is not merely a transition, but a transformation offering immense possibilities for businesses, workforce, and economies at large.

David Alatorre is CTO of Rivelin Robotics, Unit 37, 53 Mowbray St., Sheffield, U.K. S3 8EN, info@rivelinrobotics.com, www.rivelinrobotics.com.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI