Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Calibration lab tunes measuring tools and master artifacts

Mitutoyo Canada’s Calibration Laboratory provides a large scope of calibration services

- By Joe Thompson

- November 13, 2023

- Article

- Measurement

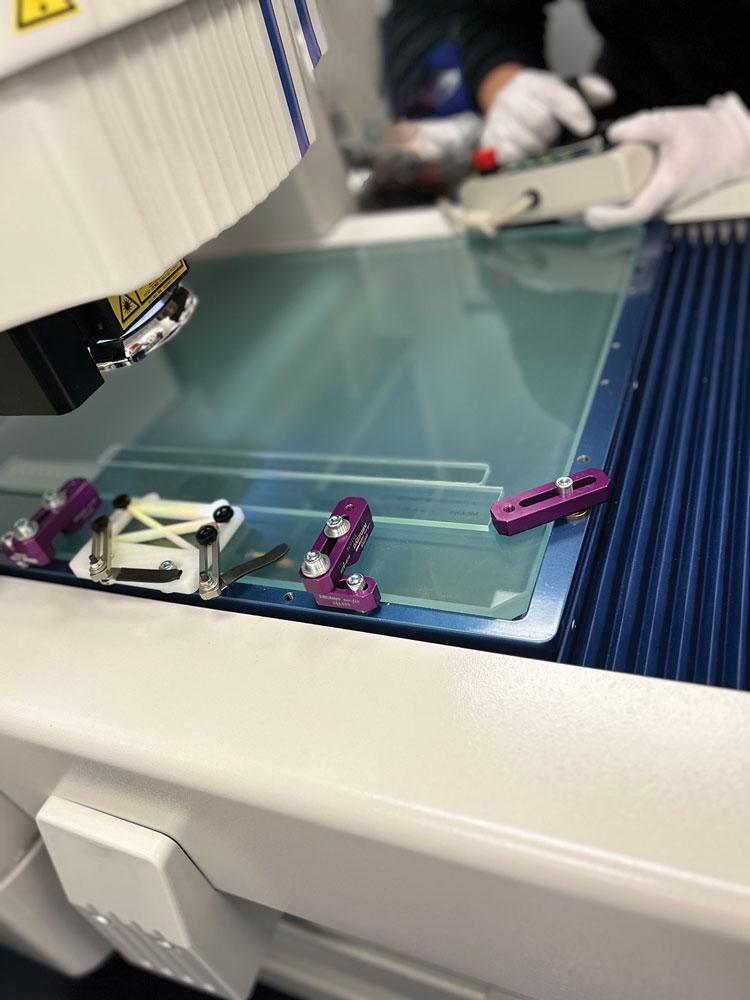

Mitutoyo Canada’s Calibration Lab supports the company’s sales staff by providing calibration services for new tools when required by its customers. The lab also calibrates the artifacts that its field service technicians use to perform on-site equipment calibrations. Images: Mitutoyo Canada

Who:

Mitutoyo Canada Calibration Laboratory

What:

A centre certified by the Standards Council of Canada as part of the Canadian Laboratory Assessment Service (CLAS) program in accordance with ISO/IEC 17025.

Where:

Mitutoyo Calibration Laboratory at 2121 Meadowvale Blvd., Mississauga, Ont. L5N 5N1.

When:

The lab officially opened in 2003.

Why:

Supports the company’s sales team, repair facilities, and field service technicians.

How:

Manufacturers can reach out at calibration@mitutoyo.ca.

As part of its 50th anniversary celebration, Mitutoyo Canada, Mississauga, Ont., hosted an open house and tour. This included a look at the Calibration Laboratory, a sales, service, and repair support shop that is a complement to the products and services made available to the company’s Canadian customers.

After the requisite speeches from company executives, self-guided tours allowed visitors to interact with staff in the Calibration Lab area, repair shop, and contract inspection lab.

In the main showroom, the company offered presentations about the Roundtracer Flash, MeasurLink Data Management system, and the entire line of the company’s measurement systems and tools. In the applied products room, the company showed its RoboTag, a MiSTAR 555 with a Yaskawa robot, the Surface Measure 1008, and a smart factory interactive display.

A tour of the Calibration Lab showed visitors what they can expect when their measuring equipment moves through the facility, whose goal is to help create the lowest possible uncertainty for a manufacturer’s measurement standards. It fine-tunes gauge blocks, step gauges, ring and plug gauges, and line scales. It also calibrates small measuring tools such as micrometers, indicators, calipers, and height gauges. One of the most important functions of the laboratory is its ability to calibrate its master artifacts and those of other calibration labs across the country.

The latest in measuring technology enable the lab to measure to the highest quality and provide quick turnaround times.

According to Israel Lumasag, Mitutoyo Canada’s customer support services manager, the Calibration Laboratory is certified by the Standards Council of Canada through the National Research Council Canada’s Calibration Laboratory Assessment Service (CLAS) program in accordance with ISO/IEC 17025:2017, and the International Laboratory Accreditation Cooperation Mutual Recognition Arrangement (ILAC MRA).

“Having a calibration lab in Canada is important to comply with international standards, maintain quality assurance, provide traceable calibration certificates, and reduce downtime and costs. Secondly, it plays a vital role in supporting our valued customers in various industries by ensuring the equipment they are using is calibrated and traceable to an accredited body,” explained Lumasag.

A first step in the calibration process is the soak.

Soak time allows artifacts to acclimatize to the Calibration Lab’s standard temperature, which is set to 20 degrees C. Whether its calibration equipment or tools that need calibration, this process is crucial to minimize uncertainty.

All of the work is done in the 1,600-sq.-ft. space set aside for the lab in the company’s Mississauga office. The lab has a climate control system that maintains temperature within +/- 0.1 degrees C. It also has a Class 10,000 Clean Room rating.

“The Calibration Lab supports sales by providing calibration services for brand new tools when required by our end users. The lab also calibrates the artifacts that our field service technicians use to perform on-site equipment calibrations and it works closely with the repair department to ensure that repaired items are working within the manufacturer’s specification,” Lumasag said.

Over the last few years, Mitutoyo Canada has made investments in state-of-the-art equipment and has hired skilled staff to run it. According to Lumasag, this has been a factor in the company’s ability to guarantee low turnaround times.

“Because of the investments, we are able to provide the quality of service that is expected by our customers while also accommodating for the department’s future growth. Mitutoyo Canada also continues to review and expand our scope of accreditation to better support our customers and meet industry requirements,” he added.

One example of the new technology housed in the Calibration Lab is its LEGEX CNC coordinate measuring machine (CMM). This system has an accuracy of 0.28+L/1,000.

“It is one of the most accurate CMMs in the world,” said Lumasag. “Its fixed-bridge structure with a moving table and high-resolution, low-expansion glass scales are key factors in maintaining the highest level of accuracy. The LEGEX gives our lab the versatility to measure a wide variety of standards to the highest accuracy.”

The latest in measuring technology enable the lab to measure to the highest quality and provide quick turnaround times.

The company also is constantly looking to expand its calibration services.

“The Mitutoyo Calibration Lab provides calibration services on virtually all measuring equipment. Send your tools into us for an ISO 17025 calibration. If there are any questions, please contact calibration@mitutoyo.ca, we would be happy to help. We can provide you with any information regarding the calibration of your equipment,” added Kevin Boodoo, Repair and Calibration Lab supervisor.

Editor Joe Thompson can be reached at jthompson@fmamfg.org.

Mitutoyo Canada, www.mitutoyo.ca

About the Author

Joe Thompson

416-1154 Warden Avenue

Toronto, M1R 0A1 Canada

905-315-8226

Joe Thompson has been covering the Canadian manufacturing sector for more than two decades. He is responsible for the day-to-day editorial direction of the magazine, providing a uniquely Canadian look at the world of metal manufacturing.

An award-winning writer and graduate of the Sheridan College journalism program, he has published articles worldwide in a variety of industries, including manufacturing, pharmaceutical, medical, infrastructure, and entertainment.

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI