Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Finding ways to level up at Niagara College

Niagara College’s WAMIC partners with industry to solve manufacturing challenges

- By Lindsay Luminoso

- February 20, 2024

- Article

- Measurement

WHO:

Niagara College’s Walker Advanced Manufacturing Innovation Centre (WAMIC).

WHAT:

A 15,000-sq.-ft. technology access centre and lab.

WHERE:

Niagara College Welland Campus, 100 Niagara College Blvd., Welland, Ont., L3C 7L3.

WHEN:

Officially opened in 2014.

WHY:

The team works with southern Ontario businesses to bring ideas to life, from concept to working prototypes, utilizing leading-edge equipment and software. It also leads SONAMI, a network of post-secondary institutions who, through their respective research and innovation centres, collaborate with small and medium-sized companies to tackle manufacturing-related challenges.

TECHNOLOGIES OFFERED:

- Concept ideation and design review.

- Design services.

- Fabrication, prototyping, and installation services.

- Non-destructive inspection.

- Performance monitoring and management.

- Rapid prototyping/3D printing.

- Metrology and testing services.

- 3D laser scanning.

- Components/parts fabrication.

- FDM materials testing.

SPECIALIZATIONS:

- Aerospace and satellites.

- Automotive.

- Construction (including building, civil engineering, specialty trades).

- Environmental technologies and related services.

- Manufacturing and processing.

- Precision metrology.

HOW:

Start the conversation by visiting www.ncinnovation.ca or contact the research and innovation team at ddipietro@niagaracollege.ca.

Twenty years ago, the federal government extended a call to colleges and universities to support innovation and research, and Niagara College answered.

Since then, the institution has focused its efforts on applied research and solving current and future industry challenges that affect local businesses.

“Ten years ago, the Federal Economic Development Agency for Southern Ontario (FedDev Ontario) released funding to support innovation and research and development goals within the manufacturing sector,” said Neil Wilkinson, research program manager, Walker Advanced Manufacturing Innovation Centre (WAMIC). “We were able to use the funding and put out a call to assist manufacturers in the Niagara region on existing projects. From there, the centre grew organically as it continued to receive grants like the Technology Access Centre grant and ones from the National Research Council Industrial Research Assistance Program (NRC IRAP) and build relationships within the community.”

The renewable Technology Access Centre grant acts as the base operating funding for the centre. With a new 15,000-sq.-ft. facility dedicated to both a manufacturing lab and office administrative space, this gave the centre the boost it needed to move forward.

WAMIC’s sweet spot is precision metrology, and it works with manufacturers in the region on a number of different projects.

“Our research agenda is driven by industry,” said Wilkinson. “It starts when a company realizes it could be performing a process better or looking to bring a product to market. Once we determine if it’s a good fit, we can get started. From the college's perspective, it’s a triple win. The project outcomes are a win for the company because they've got an improved process or a new product for the market. It's win for the college because students are getting work-integrated learning opportunities. It's a win for our faculty, who are engaged in research and staying connected to industry.”

Southern Ontario Network for Advanced Manufacturing Innovation

To expand manufacturing opportunities for industry and engage with fellow colleges and universities, Niagara College led an initiative, with the help of FedDev Ontario, to create the Southern Ontario Network for Advanced Manufacturing Innovation (SONAMI).

Founded in 2015, the network has grown to include Centennial College, Conestoga College, Fanshawe College, Fleming College, George Brown College, Lambton College, McMaster Manufacturing Research Institute, Mohawk College, Sheridan College, and Queens University Structural and Multidisciplinary Systems Design Lab.

“All these colleges and organizations are doing applied research with manufacturers around the Golden Horseshoe,” said Wilkinson. “We all have slightly different capabilities and capacities. We are collaborating together to serve industry better. We got funding, we built momentum, and industry demand for what we do has remained.”

For example, an automotive parts manufacturer recently applied to WAMIC, and the project was referred to a SONAMI partner that was best suited for the challenge. The company needed to thicken the wall around a hole as it was being machined to give it additional strength.

“There's a lot of traditional tooling-type challenges out there,” said Wilkinson. “We also are seeing manufacturers moving away from steel parts to aluminum for lightweighting. The machining challenge was directly related to this need for lightweighting and required SONAMI expertise. It’s these kinds of projects that we are able to find multidisciplinary solutions for.”

Precision Metrology

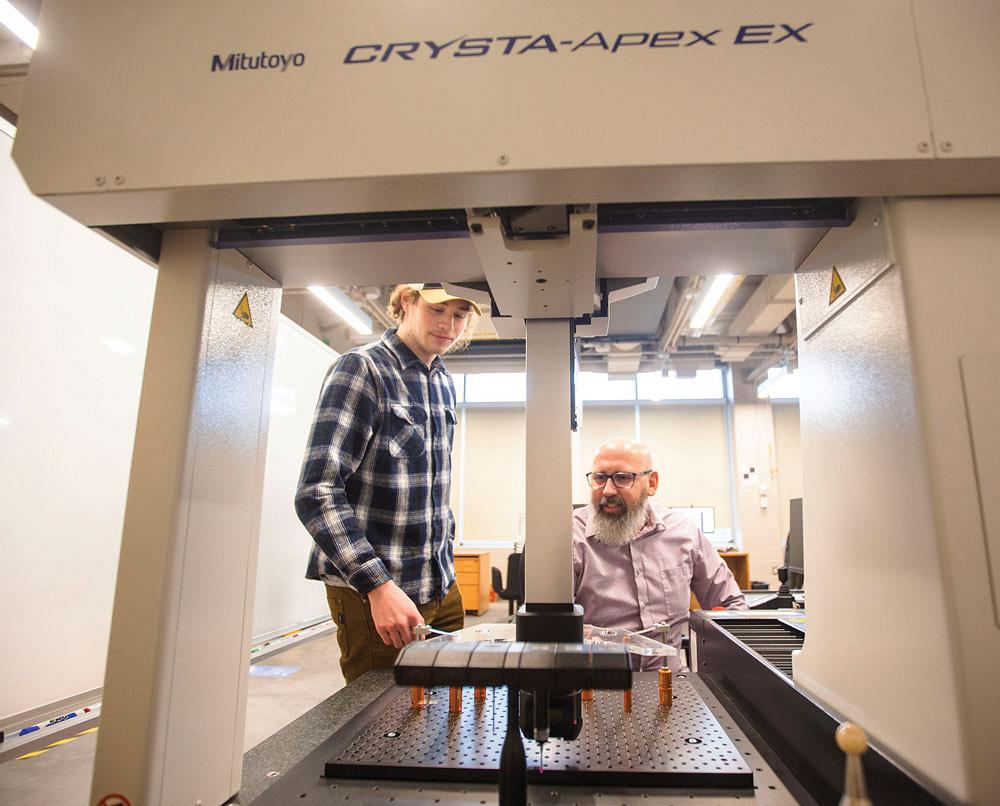

WAMIC’s sweet spot is precision metrology, and it works with manufacturers in the region on a number of different projects.

“We work with manufacturers that have very strict jig and fixture inspection schedules,” said Wilkinson. “Our experts will visit and perform regular jig and fixture inspection to verify the tooling is within tolerance. But also, we take on projects involving integrating automation into existing processes.”

The centre helps design and manufacture prototypes. For example, it is currently working to help create a semi-automated line for a heat-trace cable company to help it increase capacity.

WAMIC has a traditional workshop that includes a small CNC machine shop and Fortus 400mc and 900mc 3D printers for prototype development projects. The Fortus 900mc offers a build envelope of 36 by 24 by 36 in.

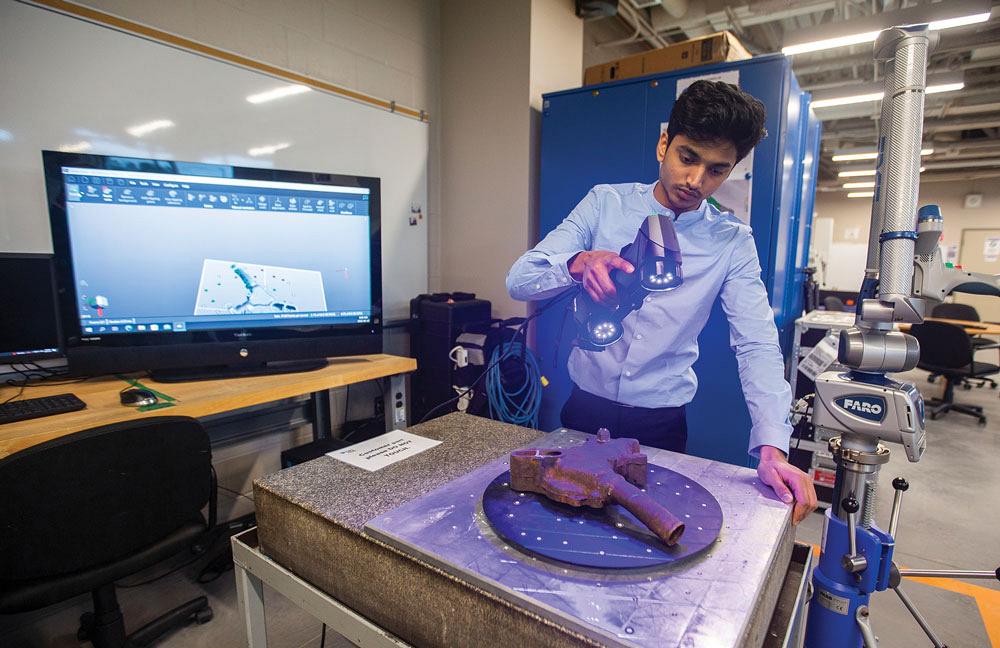

The centre has a suite of metrology equipment including touch probes, CMMs, laser LIDAR scanners, GD&T inspection software, and more.

“It’s one of the largest 3D printers on the market,” said Wilkinson. “We also have Formlabs technology, so we are able to do medical-grade, flexible plastic components with significantly high definition.”

As for metrology, the centre has a suite of equipment including a touch probe, CMM, LIDAR scanners, GD&T inspection software, and more.

“We can basically scan anything from the size of dime up to entire buildings,” said Wilkinson. “Customer demands for tight tolerances are increasing. A decade ago, maybe a 90 per cent acceptance rate on parts was good enough; now it needs to be closer to 100 per cent. Manufacturers need to be able to hit these acceptance rates.”

For that shops that don't have a dedicated metrology department, the team is able be their on-call metrology department when needed. This not only helps the company, it also helps students by giving them an opportunity to get hands-on experience with metrology equipment and to build connections within the community.

“Our goal is not to be a permanent on-call metrology department,” said Wilkinson. “Instead, we want to help shops with technology adoption. Before a company invests $200,000 on a Faro Tracker, we can teach them how to use it and how it will function within their company. We can act as an educational resource for manufacturers.”

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI