- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Supplier Side Talk: Renishaw Canada

Dafydd Williams and Philip Smith talk about metrology, additive manufacturing, and technology adoption

- February 6, 2024

- Article

- Measurement

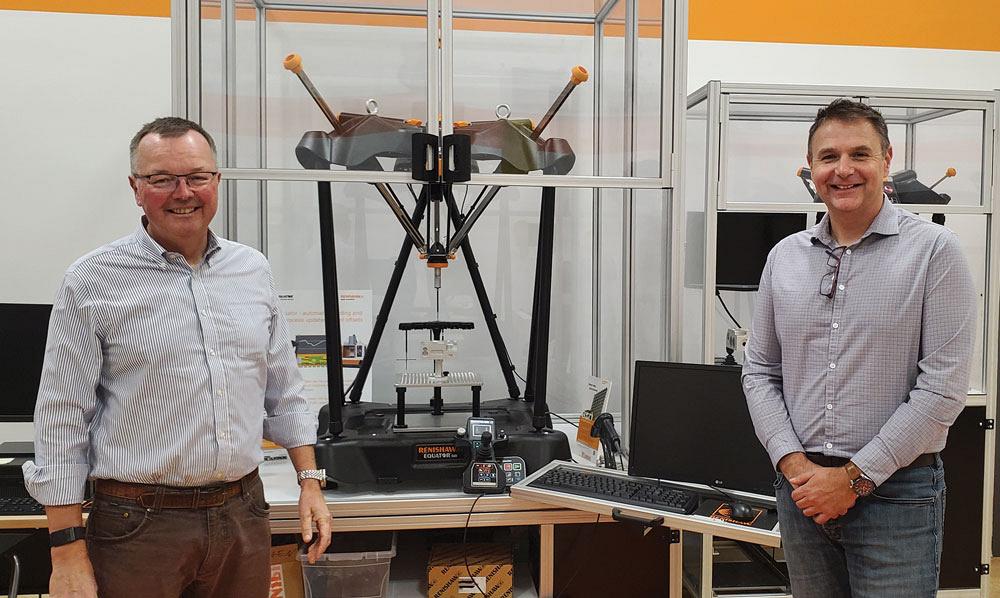

(From left): Vice-President of Sales and Marketing Philip Smith and President Dafydd Williams of Renishaw Canada sat down to talk about metrology, additive manufacturing, and technology adoption in Canada.

In 2003, Renishaw opened its Canadian subsidiary in a modest 5,000-sq.-ft. Mississauga, Ont., office/warehouse. Now, 20 years later and a short distance away from the original location, the company’s headquarters houses its office, warehouse, and showroom.

Recently, Canadian Metalworking Editor Joe Thompson spoke with President Dafydd Williams and Vice-President of Sales and Marketing Philip Smith about the company’s direction and how recent times have changed its customers’ buying habits and expectations. Here is part of that conversation.

Thompson: You’ve both been a part of the Renishaw Canada story from the beginning. What do you recall of the early years and how does Renishaw develop business in a new country?

Smith: It's quite conservative, really. When you look back at what Renishaw has done over the years with subsidiary development, it's normally fairly conservative.

We started here in Canada early in 2003, and by the end of that year there were only four of us and we all had specific skills. There were huge gaps. In those early years it was really about offering a great sales experience and talking to customers about a certain product that could help them.

Williams: Very early on we were just introducing metrology products to manufacturers and there was a tremendous education element to that.

Metrology starts with maybe just simply finding a part on the table. Then the next step for people is to use the probe to get some QA data from the part once they've machined it. But the real leap is learning to use metrology products to control the process in the first place. That's a huge education journey.

The point is that there has been a sort of evolution from showing people how to use a probe in a very basic way to helping them with process control, automation, scrap reduction, and improving processes using data.

Thompson: How has the company grown over the years?

Williams: Some of the growth has been driven by entirely new products. When we started, we didn't have a gauging product like the Equator, we didn't have metal additive machines, we didn't have a lot of the scanning products that we have now. We have a new CMM now, and of course REVO didn’t exist 20 years ago.

Renishaw has introduced the RenAM 500 Ultra for production-level work in additive manufacturing. Renishaw

Smith: We didn't have the Agility, which is our new flagship coordinate measuring machine. All of those products that Dafydd mentioned, plus this completely new CMM. We see this as natural growth for the company because we are creating all-new products for many new markets.

The mantra of the company is innovation, and that’s how we grow.

Thompson: What about the evolution of the company in terms of response times and repair times, from where you were to where you are now?

Smith: We've always placed a great deal of value on support. Support of our customers was always No. 1, which is really why we’re here. For all these years now, people tell me they like the fact that we've got bricks-and-mortar here in Canada. If they want to come and knock on our door and come and visit, they can. They know that they can have real confidence in buying product from the organization.

Williams: It's not a metric we look at to drive the business, but the bottom line is we take every repair and every service call seriously. Our goal is to keep our customers generating revenue. We don’t want them sitting around waiting when their machine is down, and they think it’s a problem we can solve.

Thompson: Renishaw is, at its heart, an engineering company. Does that help drive product development?

Smith: Globally, we are making a couple of million parts per month.

The chairman and the board have always felt very strongly that if we don't make nearly everything ourselves, we can’t control the quality. And when you think Renishaw, that's the word you want people to think about. It’s a dual meaning. It's a quality product to do my quality management work.

Williams: It's an interesting question really. We have multiple products in our portfolio that have been created by solving our own manufacturing problems.

Some of the challenges that we've had in process control—because we run multiple manufacturing sites practically lights out—is understanding where all the process variables exist, and you have to understand those. And you’ve got to measure them to understand them.

Every conversation, every install, the materials we use to manufacture the components, and even the person who shows up at your facility. For us, it’s all about quality.

Smith: Do we always get it right? No. But we try to. When things do go wrong, we offer something we call “repair by exchange,” which is extremely popular. If a probe breaks, we will send you a new one with a warranty for about one-third of the price of a brand-new one.

Thompson: The marketplace is crowded with competitors. How important is it to have differentiators in your product?

Smith: I think that the company, and especially our chairman, has always strived to create new products that haven’t existed before. That has always been something that's differentiated us from the competition. We aren’t “copiers.” Just because our competition is doing something doesn't mean we need to do it.

It’s also all driven by patents. Renishaw has hundreds of patent protections on its products.

Williams: The biggest differentiator is that we put about 16 per cent of revenue into R&D. We are a £600 million company, which is about $1 billion Canadian, so that’s a lot of money going into research. This is what creates differentiators in our products. Sometimes they're subtle, but they're there.

Thompson: People sometimes make purchasing decisions based solely on price. How do you get to those customers?

Williams: Sometimes, you can't.

Smith: This also goes back to the support structure we have. We have a bricks-and-mortar location, we've got product here, and we've got people that can help you integrate those products here. And, importantly, we have people who can reach all parts of the country.

Thompson: Do you see customers buying because of brand loyalty?

Smith: I don't really believe in the concept to brand loyalty anymore. At the end of the day, we're only as good as the last performance we gave. People are loyal to good service, they're loyal to being looked after, and they're loyal to getting innovative products that drive down their bottom-line costs.

So you're working on your brand all the time, essentially.

Williams: You are only as good as your performance.

Thompson: On-machine probing seems to be having a resurgence in popularity. What is driving that?

Williams: When you turn the clock back 20 years, if you bought a 5-axis machine, it probably shipped without any kind of probing system. Today, in my opinion, it’s a fool’s errand to use a 5-axis machine tool if it doesn’t have a probing system.

Smith: A few 5-axis machines may be sold without probing, but most of them are going to have it. Twenty years ago, that wasn’t the case.

Thompson: Is this related to not wanting to sacrifice cycle time for a probing cycle?

Smith: That's always been the key and it’s never going to go away. But we've come up with other tools so you don't have to probe the component on the machine. You might be able to take it off the table and gauge it on an Equator. All applications are different, but there are ways to get around the cycle time debate.

Thompson: So what is on-machine probing for?

Smith: It can be as simple as establishing where the part is on the table or doing a zero out. Or we can create a cycle to check that holes are in the right position before a tapping operating is performed.

The role of the probe can vary to include just about anything.

It’s not often that we speak to a customer that is not talking about cycle time, which is why over the last six or seven years we've also come up with a means of optimizing a lot of our probing cycles. We are shortening them by removing unnecessary touches and we’ve reduced the time it takes to perform a probing cycle.

Williams: Let's take a really simple use case. You're machining a casting. How much material needs to be machined? What cycles do I need? Do I need to hog-off a lot of material from one part of the casting and very little on another part? This can only really be figured out using the data from a probing cycle.

Thompson: At a time when technology seemingly advances exponentially, is it even possible to look ahead to the next 20 years of Renishaw? If so, what does the future look like?

Williams: The good thing is that the company has no lack of ideas. We're not limited by anything and we're developing a lot of new technologies.

If you look backward 20 years, Renishaw had didn’t have a CMM or additive machines. So what does it look like 20 years from now? More of that, I think. I think that there will be more capital-style equipment like new additive products and measuring machine products. And I think, just like we’ve done with the dental industry in the past, that we will have much more of a medical industry focus than we do right now.

Renishaw introduces new production-style AM system

To give metal additive manufacturing (AM) users the tools to produce parts faster, global engineering technologies company Renishaw has expanded its RenAM 500 series with the launch of the RenAM 500 Ultra AM system.

The system delivers significant productivity benefits, according to the company, by cutting build times by up to 50 per cent without compromising on quality.

It includes all of the existing benefits of the current RenAM 500 series, including its optical, chamber, and gas-flow design, and adds the newly launched TEMPUS technology and new process monitoring software.

TEMPUS technology incorporates new scanning algorithms that allow the laser to fire while the recoater is moving, saving up to nine seconds per build layer. Furthermore, the process monitoring software delivers detailed insights into the build, equipping users with data and providing in-process visibility.

The entire RenAM 500 family of products is available with one (500S) or four (500Q) lasers, each able to access the whole powder bed simultaneously.

“Ultra is the ultimate system for productivity in Renishaw's current range,” said Louise Callanan, director of additive manufacturing at Renishaw. “We designed it for AM users who want full-scale production at the lowest cost per part.”

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI