Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Break the mold

Tesan Mould takes an innovative and forward-thinking approach to moldmaking

- By Lindsay Luminoso

- March 13, 2024

- Article

- Metalworking

(From left) Brothers Jesse and Lucas Tesan now run Tesan Mould, a company their father Riccardo built in 1978. Images: Tesan Mould

Tesan Mould Inc. prides itself on its family-focused business model. Founded in 1978 by Riccardo Tesan, the moldmaker has been owned and operated by the Tesan family ever since.

Riccardo Tesan emigrated from Italy to Canada in the mid-1960s and worked in various machine shops perfecting his skills in lathe and turning work. Moving up, he was promoted to lead hand and manager of an injection mold company in Toronto. But by the late 1970s, he became increasingly interested in branching out on his own.

Tesan Mould began as a two-person operation in Downsview, Ont., focusing primarily on moldmaking for the automotive and housewares sectors. The mid-1980s saw a huge spike in automotive moldmaking, which became a strong market segment for Ontario manufacturers.

“There was a point in the mid-80s where the company was 100 per cent automotive based,” said Lucas Tesan, vice-president, Tesan Mould. “However, there was a turning point where we started to acquire a lot of new technologies. Over the years, we graduated towards more complex molds and expanded from there.”

Fast forward 46 years, the company has grown, moved, and transitioned to a 30-person plastic injection mold manufacturer run by Riccardo’s sons, Lucas and Jesse.

“My father is still active in the company after all these years,” said Tesan. “Our main business is plastic injection moldmaking, designing, and prototyping for the packaging and logistics sectors. We also deal in plastic and metal technologies, like plastic prototyping with plastic parts, complex machining such as grinding, 5-axis milling, gundrilling, grinding, and welding. We have a large array of equipment.”

The company moved from Downsview to Vaughan, where it currently resides in a custom 35,000-sq.-ft. facility.

Family-To-Family Business Model

Over the years, the company has acquired a lot of customers, many of which are family-owned businesses too. Tesan has spent decades building these family-to-family connections.

“The family-to-family business model is fairly typical in Europe because a lot of businesses are family businesses, and even big corporations are still family-owned,” said Tesan. “In Canada and North America, there tends to be family businesses working with conglomerates, public companies, or large organizations with huge structures. We found a niche in the 80s focusing on the family-to-family business model and supporting Tesan and employees’ families by working with other family-owned plastics companies within Ontario, Canada, and the U.S. A lot of these family-owned businesses in plastics latched onto our family business, and we developed that one-on-one respect you get with working with another locally owned company. Since that time, a lot of the plastics companies really took off and grew, and they kind of stuck with us.”

Many of those customers have built longstanding relationships with the company’s long-term employees. Tesan noted that because of the longevity of these relationships, there is an emotional and financial interest in seeing customers succeed.

Tesan Mould has grown, moved, and transitioned from the two-person automotive moldmaking operation to a 30-person plastic injection mold manufacturer in Vaughan, Ont.

The company works with customers small and large across the U.S. and Canada.

“It’s important to treat everyone with equal importance and respect,” said Tesan. “Problems are different in scope and size, but we have always focused on giving every one of our customers that one-on-one attention they deserve from us.”

Tesan noted that the company’s sweet spot is in building high-quality molds that are proudly made in Canada. For the shop, it’s not about finding extreme cost-saving measures like working with low-quality material or outsourcing overseas; instead it’s about building relationships with customers and offering competitive pricing.

“We design and build our products using Canadian and American suppliers, and while price is always an issue, we compete with local competition but still operate in a sector of profitability, which is important for reinvestment and innovation,” he said. “We have a good select group of customers that demand constant quality and competitive pricing. And that's what we strive for—a mutually profitable relationship.”

Being Bold With Equipment Investment

One of the reasons for the company’s success is management’s focus on investing in next-generation equipment.

“We had one of the first large-scale CNC machines,” he said. “In the 1980s, we had one of the first computer desktops and 3D software including Camaxis, Cimatron, and Silicon Graphics, the last of which was a big system back in the 80s. Our focus has been on investing in high-quality European machinery.”

The company’s biggest competitive advantage is that it’s a small to medium, privately owned shop with a very large footprint and cache of machine equipment.

Most recently, Tesan Mould invested in a large DMG MORI 5-axis mill-turn machine. While it is unusual for a small shop to have a budget for this type of complex equipment, Tesan noted that one thing management has always done is take risks.

“We make room in our budget for the latest cutting-edge technology,” he said. “We want our technology to lead the way, like with our new mill-turn or our 5-axis gundrill. Our machines are ultra-productive with the latest up-to-date software, Siemens NX. These are all very expensive platforms to participate in, but we found a way with our customers and suppliers to become profitable and invest in this type of equipment.”

For Tesan Mould, it’s all about reinvesting in the future to gain advantages that help it to keep moving forward.

For example, for many years, the company outsourced its mold testing. It put off bringing an injection press in-house because of the expense of the equipment and the need to hire a full-time operator to run it. But when it had the budget for it, the company purchased a Husky press, which was identical to ones that its customers use. That way, they were able to test molds in-house and have full transparency.

“It also is a selling point for us,” said Tesan. “Having an in-house machine helps remove a lot of risk for the current customers, and it removes a lot of risk for potential customers in dealing with us, knowing that we can test and prove out anything we need to. We are always looking for new technology to increase our customers’ expectations of what we can provide by getting faster deliveries and tighter tolerances.”

While the company is not currently looking at adding to its equipment list, Tesan believes that another 5-axis mill-turn machine would be ideal to help the company produce round pails and lids.

“There seems to be a shortage of round mold and round capacity in Ontario,” he said. “It seems like most people only want to do 3- or 4-axis machining. Nobody wants to do round turning or spinning. That's something that we've always done for 40 years, and we will just stick with that.”

Another future investment would be a 3D scanner or a scanning coordinate measuring machine (CMM) to reverse-engineer parts as the company takes on complex mold repairs from other suppliers. Anything from the packaging sector that needs a repair, like pales, lids, or pallet molds, Tesan can reverse-engineer any mold component. The company has a CMM, but a large-scale, 5-axis scanning CMM or a hand-held 3D scanner would help the shop scan intricate details and take on more complex work.

Staying Ahead of the Sustainability Curve

Tesan’s main focus is on high-speed packaging, which can range from deli containers and thin-walled takeout food containers to ice cream tubs and lids. It also breaks down to logistics as well; anything from shopping baskets, wagons, handles, buckets, thick lids, painting trays, pallets, dollies, to folding crates.

“Our goal is productivity,” said Tesan. “What that means is determining how to produce the best products at the lightest weight with the fastest cycle time. We range from a throwaway paint tray that's full of paint to an ice cream tub that is very thin, high-speed, hermetically safe packaging. They're all tied in together by our ambition to manufacture the most productive molds.”

Tesan Mould’s packaging customers are constantly searching for new lightweight plastic or avant-garde plastics to put in their packaging to make the packaging productive, cheaper, and more sustainable. And to compete in this space, Tesan needs to think about future productivity through material changes.

“We see a future in the transition from plastic to fibre packaging,” he said. “It's the same type of molding and manufacturing in our factory, but the injection material is different. So now we have to learn how to inject plastic biofibres into the molds. We're very forward-thinking with sustainability, recyclability, and packaging design. It's all pushing the envelope and trying to improve on the status quo. Working with sustainability and recyclability criteria requires better, more expensive tooling.”

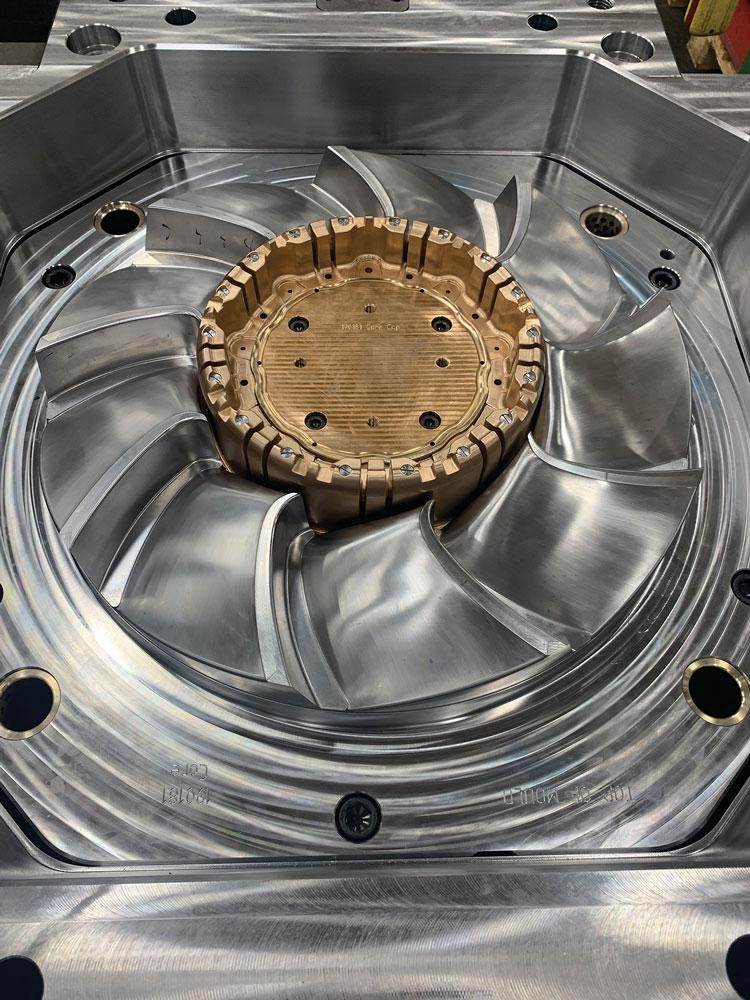

It’s not just materials that are changing, design also has become increasingly complex. For example, for many decades, flowerpots often only came in a tapered or bowl shape. However, Tesan Mould was one of the first companies to test out new multicavity, ultra-thin-walled, complex molds.

That’s when it started attracting customers who push the envelope in flowerpots. The company learned how to make a swirl, and then a swirl with texturing. Today, there are some exceptionally unique pots thanks to the innovation and forward-thinking of companies like Tesan Mould.

“We are proud to be involved in mold manufacturing, working alongside our customers to develop new and unique molds and work with the latest materials.”

Materials change. For a long time, the shop worked with customers using polypropylene. Then, as sustainability became important, molds began using recycled polypropylene. This meant designing a mold with better flow or a different hot runner or injection system. Even now, materials are slowly moving towards plastic with biofibre to make them more biodegradable an easily recycled.

“We work a lot with Husky to adapt to these materials,” said Tesan. “I'm involved with the Canadian Association of Moldmakers, and recently there has been a lot of discussion about sustainability and resin supply. I try to translate all that knowledge back into my business, testing, and mold development. It’s also about sharing this innovation with customers so we can help each other stay ahead of the curve.”

Associate Editor Lindsay Luminoso can be reached at lluminoso@fmamfg.org.

Tesan Mould Inc., tesan.com

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI