- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business Profile: A small company thinking big

Rian Solutions, Brantford, ON

- By Canadian Metalworking

- April 6, 2015

- Article

- Metalworking

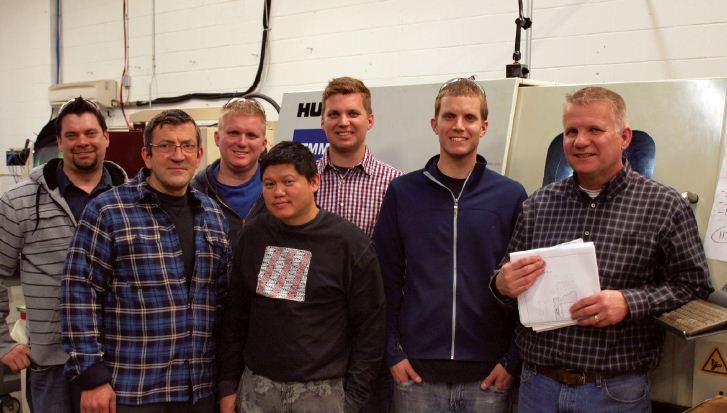

A solid handshake and a pleasant smile is the welcome you receive when meeting the father and son team who manage Rian Solutions in Brantford, Ontario. A young custom machine shop, it was the son, Brian Vaandering who launched Rian Solutions in June 2011 with his father Henry’s support and guidance.

Born and raised in Brantford, Henry is a machinist with over 30 years of experience in the manufacturing business. He was one of the founders of a successful local shop specializing in injection molds. That business grew to 80 staff and a plant of 20,000 sq. ft. Henry was president of the operation when it was sold to an international conglomerate in 2009.

Brian grew up in that machining environment, working on a regular basis from his early teens. It was about three years after graduating from business school at Redeemer University in Ancaster, Ontario, that Brian made the move to start up his business.

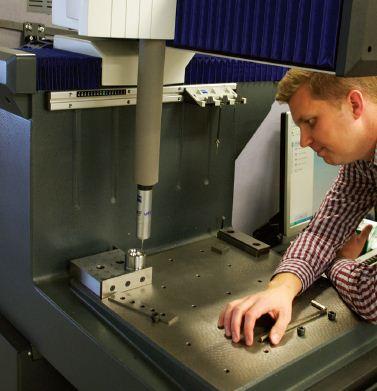

Among his first purchases was a coordinated measuring machine (CMM), a CNC lathe, and a CNC mill. According to both Brian and Henry, the CMM was a critical component and foundational to the business. “What differentiator do you have if you only have a CNC lathe and a CNC mill?” notes Henry. “All you’re selling at that point is your ability to remove metal. The theory was, if we can measure it, we can make it,” he says.

The idea was that Rian Solutions would be able to validate every product, providing customers with confidence, backed up by data.

Another step to bolster their customers’ confidence and further differentiate their offering was to become ISO 9001 certified, which they accomplished in October 2013. From day one, Brian began flowcharting every key process in the business. “It’s just good business practice,” he says, adding that going through the certification makes you think your processes through in a logical fashion. They also knew that their target customers were going to require ISO certification.

The company’s sales approach has also been very deliberate, making efforts to “qualify” the customers they work with. As a solutions provider, they want to be able to partner with clients, inserting their manufacturing knowledge into their clients’ value chain.

“We’re looking for customers that have design, assembly, sales and service,” emphasizes Henry. “What we try to do is develop a plan that’s going to support their manufacturing by producing products they’ve already designed.”

They’re also seeking clients with a similar business philosophy; that is, a company open to a collaborative and creative working partnership. “We’re looking for customers interested in supplier development,” says Brian.

As a prime example, the Vaanderings have been working with a customer who has developed new energy-efficient transmission technology, and they are confident the demand for this industrial equipment—which is just hitting the market—will grow and become a significant portion of their business over the next three to five years.

“That’s what we’re hoping for anyway,” says Henry with a measured confidence.

A large portion of Rian Solutions’ current work is in the mold, tool and die sector, with inroads into power generation, agricultural machinery, military, dental and industrial automation. The services they provide include turning, milling and grinding as well as the CMM and reverse engineering.

Since start up the company has installed additional machine tools including three Hurco machines—a five-axis mill, four-axis mill and a three-axis lathe. They were drawn to the Hurco products while visiting the IMTS trade show in 2012. “We brought drawings with us to the show,” recalls Henry. “The Hurco demonstrators were able to program the parts at the machine as fast as it would take us to load the drawings into a computer.”

They felt the conversational programming ability for basic machining operations on the Hurco stood out. “It was a clear differentiator for us,” says Henry. “Instead of needing someone working offline, the operators are able to take the drawings and create their own programs at the machine.”

This ability saves valuable time and allows the business to keep its costs down. The Vaanderings also point to the ability of the machines to be programmed and prepped while they’re running as another key productivity enhancement.

The Hurco installation began in December 2012 and both men comment very favourably about the service and support they’ve received from Elloitt-Matsuura Canada. “They were able to help us take the steps required to learn the software, and start to offer these additional machining services,” says Henry.

Brian was particularly impressed with the short learning curve. “Our operators who were trained on them had no programming experience whatsoever, and through the training with Elliott and Hurco they became self-sufficient in a very short amount of time.”

Loyalty is a core element to Rian Solutions’ community-minded business approach, so they treat their suppliers the same way they treat their own customers.

“We buy everything from Elliott because of the service and support they provide,” notes Henry. And the company has since purchased a Matsuura 520 five-axis mill to accommodate some larger parts they’re working on.

Going forward, with their eyes on further servicing the medical industry, Rian’s next purchase will likely be a smaller machine for finer small part precision machining.

Built in to their business processes is a commitment to continuous improvement. Part of that includes building strong relationships with its tool suppliers.

“As a custom machine shop, finding quick solutions becomes necessary as our product mix changes frequently,” says Henry. In some cases they may have a short window of time to call on suppliers to get the proper tooling for new machining applications. “We’ve targeted three main distributors of cutting tools to partner with and bring solutions to us,” notes Henry. Again, building relationships built on loyalty and mutual respect.

Looking forward, the company has a five-year business plan, and they know where they want to go and how they want to get there. They’ve been experiencing 15 to 20 per cent growth year over year, and that continues to be their target for the next few years. “We have a pretty good idea that it will happen,” nods Henry.

At launch Rian Solutions was only Brian alone, and within six months there were two people, and the employee count has been growing ever since. They’re now up to 14 employees, including Brian’s two younger brothers. This past November the business expanded, moving into a vacant next-door unit, growing their space to 6,000 sq. ft.

With stable business processes in place, Henry suggests that by 2016 they’ll begin automating aspects of their production. “We have goals that we will automate our milling machines in 2016,” he says, noting that they expect to put System 3R common pallet on their equipment.

They don’t anticipate the company growing much beyond 20 employees, but they will continue adding equipment and automation. “Can we grow the business using the intellectual power we have and automate what we do?” asks Henry, answering, “That is the goal.”

Both suggest that the biggest obstacles they face are time and resources. “When you’re a small company you have more responsibilities. Time becomes the challenge—time to get everything done

that you want to do,” says Brian.

They estimate that 20 per cent of their time is still spent on the shop floor. “You need a careful balance between working on the business and working in the business,” says Henry. “It’s finding that balance so you keep your order book full and you’re keeping to the business plan that you have.”

They admit that machining is a stressful industry with short lead times, where it’s a challenge to meet customer demands. If something goes wrong during production there is very little time to recover, or working with an unfamiliar material requires dexterity to adapt and manage the request.

“So many companies talk about trying to exceed customer expectations,” says Henry. “But most people will be very satisfied if you meet their expectations—delivering a quality product, on time, in full.”

In their presentation to prospective customers they spell out how they are “passionate about machining. We love what we do.”

“We love the difficulties, the problem solving,” says Brian.

Collaborating with customers, employees and suppliers, being creative to develop their services and delivering quality products, that’s why they put “Solutions” in their name.

Henry smiles as he retells a very satisfying comment he received from one of their main customers. “You’re a small company that thinks like a big company, and services us like a big company.”

That’s just the way Rian Solutions wants to be seen.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI