Vice-President of Global Sales and Business Development

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Copper alloys find their place in the world of additive manufacturing

Additive manufacturing of advanced copper alloys poses distinct challenges

- By Zach Murphree

- November 8, 2023

- Article

- Metalworking

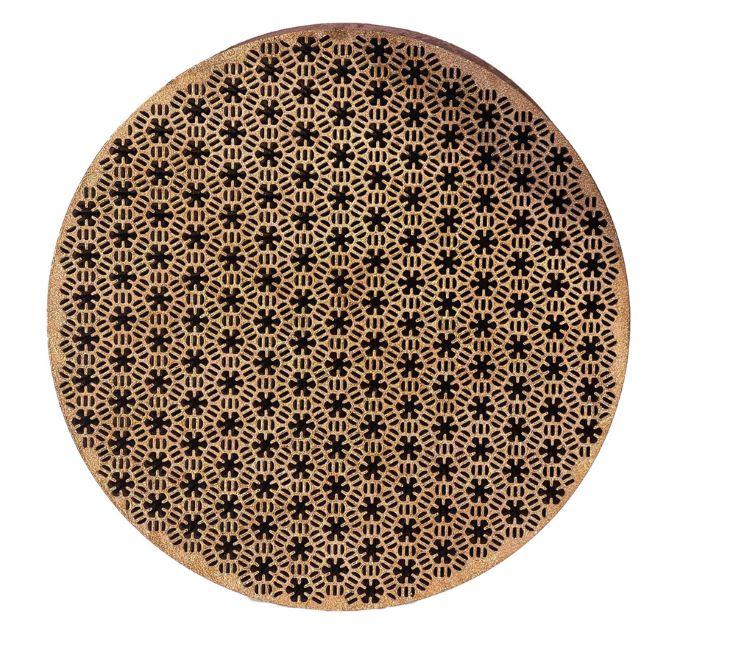

This cross-sectioned thrust chamber was printed on a Velo3D Sapphire system in GRCop-42. The chamber walls contain internal channels for regenerative cooling. Velo3D

Copper is one of the hottest metals attracting attention in the additive manufacturing world these days. The metal has excellent thermal conductivity, which is desirable in rocketry, as well as in more grounded applications such as electronics, for which heat exchange is critical.

This thermal conductivity capability stems from the copper atom’s single, free electron in its outer shell that can transfer a high level of energy over a distance with little to no resistance.

Second only to silver among metals in its ability to conduct heat, copper also is significantly less expensive pound for pound, which is attractive to rocket developers. In its pure form, copper is relatively soft. For the advanced part production in additive manufacturing (AM), it’s typically mixed with other metals into alloys that provide enhanced mechanical properties along with that valuable conductivity.

Common copper-based materials for AM include GRCop-42 and GRCop-84 (both are copper chromium niobium alloys), C18150 (copper, chromium, and zirconium), C18200 ( copper and chromium), and GlidCop (copper and alumina). The colour of copper alloy powders is a soft pink, with finished AM parts displaying the classic copper colour.

NASA Leads Copper AM R&D

While NASA pioneered the use of copper alloys in the 1970s on the space shuttle’s main engine, that use was at first limited to forged components.

GRCop powder metal was developed by NASA metallurgist David Ellis as an improvement on the earlier forged alloys and used with vacuum plasma spraying, a form of direct energy deposition AM that produces relatively simple, large structures.

But it wasn’t until laser powder bed fusion (LPBF) became available—and with enough laser power to work with copper—that copper powder became a suitable metal for AM technology. Carried out in an airtight build chamber, LPBF creates very complex internal geometries for the latest rocket combustion chamber designs, and also for cold-plate applications in electronics.

These AM-enabled, complex geometries are of particular interest to engineers designing lighter-weight rockets with novel propulsion configurations for launch vehicles, hypersonics, and other applications. A rocket’s thrust chamber needs to have material properties that can withstand the thermal and pressure extremes of ignition. But because it is essentially functioning as a heat exchanger, the chamber also must withstand a surrounding flow of super-chilled rocket propellant. Such a fluctuating environment can be precisely balanced using 3D-printed intricate cooling channels in the surrounding walls of the thruster. These geometries cannot be achieved using any other type of manufacturing.

The best material for this kind of system is copper, which lines the combustion chamber.

Material Considerations

The road to high-value parts always begins with the quality of the materials employed, and it’s been no easy task combining copper with other metals into the alloys that are essential for 3D printing high-value parts. Most AM system manufacturers do not atomize powders in-house; they are dependent on powder suppliers to deliver the raw material ingredients their machines require for optimum results.

GRCop-42 is used to craft an aerospike thruster prototype, shown here on build platform after 3D printing. Knust-Godwin

Those materials suppliers have been challenged by copper’s relative softness and stickiness, which make it difficult to combine with other ingredients. Some copper alloys rely on dispersion strengthening for enhanced mechanical properties. With GRCop-42, for example, a crucible containing copper, chromium, and niobium is superheated until the chromium and niobium dissolve into the liquid copper. When the alloy is atomized via flash-freezing into a very fine powder, the chromium and niobium combine into what’s called an intermetallic. The smaller the intermetallic dispersed within a powder particle, the higher the mechanical properties (strength and fatigue- and creep-resistance) of the material. This helps mitigate the heat-flux (very hot on one side, very cold on the other) in the liner of a rocket thrust chamber.

“You can’t get that key intermetallic formation of copper in an ingot,” explained Jamie Cleland, a materials expert with decades of R&D work in rocketry who’s now a California-based consultant. “GrCop is only able to be manufactured as a powder. It was essentially a powder looking for a process before it found its niche in 3D printing.”

The NASA Way

Cleland added that Paul Gradl, a principal engineer at NASA’s Marshall Space Flight Center, is widely credited for taking the lead on the use of powdered copper alloys for AM.

Starting in 2014, NASA began developing GRCop-84 for printing rocket combustion chambers. It then moved to GRCop-42, which had improved conductivity—important in extreme heat-flux environments—as well as the faster build speeds that are always attractive in AM work.

Gradl reported that, in some cases, the move from conventional manufacturing to AM resulted in cost reductions of more than 50 per cent and lead time reduced by up to 10 times.

Convinced of the value of copper for rockets, NASA stayed the course with GRCop-42, and now, after admittedly quite some time in R&D partnerships, has achieved its goal: GRCop-42 has been certified by several of the more advanced LPBF system providers, as has the newer C-18150. Other copper alloys currently are undergoing certification trials.

Overcoming Obstacles

Now that private corporate startups have begun seriously working with NASA to launch rockets, deliver satellites, and develop hypersonic aircraft, the rush is on to secure powder stock and harness the capabilities of the latest copper alloys.

Progress has been somewhat uneven as materials providers have had trouble striking the correct balance between best mechanical properties and yield/cost of manufacturing powder to meet chemical composition specifications.

“The powder-atomization industry was definitely having challenges just making copper alloy powders,” said Cleland. “As a result, there was more variability in those powders than other more mature ones like INCONEL.”

There also are fairly steep learning curves for both AM machine builders and operators who may have limited experience working with copper. Things have improved significantly in recent years, however. AM systems continue to evolve, and the materials industry has begun working to better standardize powder manufacture and sourcing.

This GRCop-42 heat exchanger was produced by Launcher, a VAST company, to simulate the combustion chamber regenerative cooling channels of its E-2 rocket engine. This heat exchanger has been hot-fire-tested by Launcher in its testing facilities. Launcher

Nevertheless, supply chain problems caused by the global pandemic still linger. Recently, some AM system providers have been working more closely with leading materials makers to secure contracts providing a reliable supply of highest-quality powders for their customers. The larger 3D-printing systems now on the market are also a better size-match to rocket-engine requirements.

As the sophistication of AM systems rises to match the variety of challenges of working with copper, successes are being realized, overcoming numerous obstacles:

High Reflectivity. Most LPBF systems use a fibre laser that operates at near-infrared wavelengths, generally around 1,070 nm. It turns out that copper alloys are extremely reflective at these wavelengths, with up to 95 per cent of the laser energy directed at the material bouncing off of the metal and into the walls of the build chamber. This means that these systems require even higher-power lasers (in the 1-kW range) to initiate the melting process. Effective cooling systems in the walls of a copper-qualified printer also are necessary.

Interestingly, once enough directed laser power has hit the material to begin melting, copper transitions from reflecting to absorbing energy. At this point, copper’s innate conductivity comes into play, changing the dynamics of the melt pool as it sucks energy away from the centre more quickly than other materials do.

The AM system and processing parameters then have to balance the two different modes of the melt pool—conductive (broader, shallower) and keyhole (deeper, light-trapping)—to ensure that control is maintained and successive layers cohere properly.

Stickiness. Copper alloys are relatively soft and gummy compared to other materials commonly used in AM. This can create issues in sieving, powder conveyance, and leftover powder removal after manufacturing. CT scanning is used to analyze the powder’s composition and density, as well as verifying proper de-powdering after a print.

The layer-by-layer process of LPBF also is more of a challenge with copper alloys because their stickiness can make it difficult to achieve even recoats of powder over the build-bed. A non-contact recoater is a distinct advantage here because it never touches the bed or the growing part within it.

Oxygen Sensitivity. Gradl’s work on GrCop demonstrated that the thermal conductivity of the alloy is highly dependent on, and inversely proportional to, the oxygen content of the printed material. Any oxygen that gets incorporated into the microstructure of the alloy will keep it from conducting as well as it should.

Particularly in the larger build chambers now available, the importance of maintaining a very low oxygen level in the chamber is paramount. Inert argon gas is the preferred build chamber medium when working with copper.

Control and Compete

“Once you know the tradeoffs of copper material, process control is clearly the key to success with printing with it,” said Cleland. “Layer-by-layer quality assurance checks that monitor an hours- or days-long print are critical.”

This internal segment of a GRCop-42 heat exchanger was produced by Launcher, a VAST company. The part showcases the design and print quality of the internal cooling channels used in the heat exchanger. Launcher

Data collected from sensors during a build informs process development teams at the major AM system providers as they fine-tune parameters for working with more challenging materials like copper.

Meanwhile, NASA is continuing to advance the technology for AM using copper alloys for combustion chambers. As well, several vendors have been established to provide these designs as a commercial printing service, and NASA is using vendor-supplied chambers as part of development testing under various programs.

The democratization of AM continues, with even SME rocket manufacturers now able to buy, lease, or access 3D printing through a contract manufacturing network. The opportunity is ripe to take advantage of the potential of this more mature technology, along with performance-enhanced materials, and enter the competition on an increasingly level playing field.

Zach Murphree is vice-president of global sales and business development for Velo3D, 511 Division St., Campbell, Calif. 95008, www.velo3d.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI