Product Manager

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Increase tool production using automated blanket grinding

Continuous production from barstock to finished tool saves time, costs

- By Kaine Mulder

- November 27, 2023

- Article

- Metalworking

Blanket grinding is defined as continuous and complete tool production from longer barstock to finished product using automation.

Supply chain disruptions, a lack of skilled labour, raw material shortages, freight delays, and increased energy costs are all affecting manufacturers. The need to adapt to these changes has become significantly more important, particularly because they are being exacerbated by demand and driven by expectation in our instantaneous global culture.

ANCA works with its customers to adapt to these market changes and pressures. One such example takes advantage of blanket grinding, which now is automated using unique robot cells offered on each of its platforms.

What Is Blanket Grinding?

Blanket grinding is defined as continuous and complete tool production from longer barstock to finished product using automation, which saves time by eliminating extra processes and handling.

Utilizing ANCA’s grinding machine platforms with a robot cell, blanket grinding offers flexibility across numerous tool sizes and applications. It allows for full automated production of tools with similar geometries by consolidating all tool grinding processes into one single machine. A batch of completely finished tools can be produced without interruption directly from lengths of ground barstock with no operator intervention.

This ultimately gives users the flexibility to respond to customer demands in a dynamic and agile manner. A pallet of ground bar material is loaded into the cell, and the machine takes care of the rest.

The blanket grinding approach is suitable for small batches, quick turnaround production, product development and R&D, and lights-out operating.

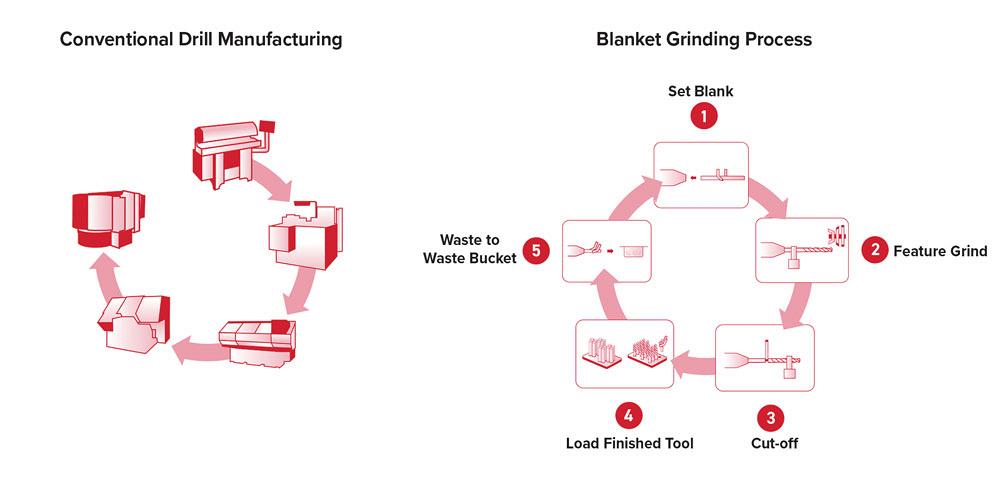

Blanket Grinding Process

The process starts with a full 330-mm barstock material being loaded into the collet. The blank and tool geometry is then ground, including any features (such as a rear chamfer), before the finished tool is cut off. The tool is then removed by the robot and loaded into the finished pallet. These operations are repeated along the remaining barstock until all of the useful raw material is consumed. To complete the automation process, waste is handled by the cell before new barstock is loaded into the collet.

ANCA’s machine platforms—with the addition of a robot cell—can all be used to implement the blanket grinding process. Tool size and application determines machine choice.

The two main features offered by the TX platform that are beneficial in performing blanket grinding are its large working envelope and its high-torque spindle. These attributes allow work to be performed on long bars and enable production of different tool sizes and geometries without limitation, including tools that require a lot of material removal.

The TX platform also fits any of ANCA’s robot cell systems, including RoboMate and the dedicated TXcell offering, which is a large-format cell automation system.

By consolidating all tool grinding processes into one single machine, a batch of completely finished tools can be produced without interruption directly from lengths of ground barstock.

The RoboMate cell is offered on both TX and MX platforms.

Benefits of Blanket Grinding

Products that are more unique and have higher complexity—but more importantly, include immediate response and shorter delivery times—are in high demand by tooling end users. When meeting these expectations, costs take a back seat, while the focus is on delivery.

Using blanket grinding enables helps meet these demands with minimal disruption to existing production lines. Less planning is required, manual handling is reduced, and utilization is increased. These benefits compound to deliver a better overall value proposition and increased return per tool.

Blanket grinding may also create a reduction in required floor space by removing separate machines and consolidating processes into a single footprint to produce the same tool. This process consolidation allows changes in parts and features to be easily handled.

For example, grinding shank features, such as Weldon flats or coolant slots, is made easier by enabling the production of different features in a single setup.

Become More Agile

Quickly respond to customer requests without the need for re-tooling or disrupting high-volume production lines.

Applying blanket grinding also goes a long way to improving cost recovery, by taking advantage of the increased utilization efficiencies and removing manual labour and setup times.

Blanket grinding can reduce costs through:

- Increased machine utilization.

- Reduced stock waiting in-process.

- Minimized manual handling.

- Reduced tooling and setup (single machine setup, no multiple stations).

Kaine Mulder is product manager for ANCA CNC Machines, 31129 Century Dr., Wixom, Mich. 48393, 248-926-4466, www.anca.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI