- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Industry Update: Medical part manufacturing

Grinding machine is on the ball for hip implant production

- By Canadian Metalworking

- September 12, 2022

- Article

- Metalworking

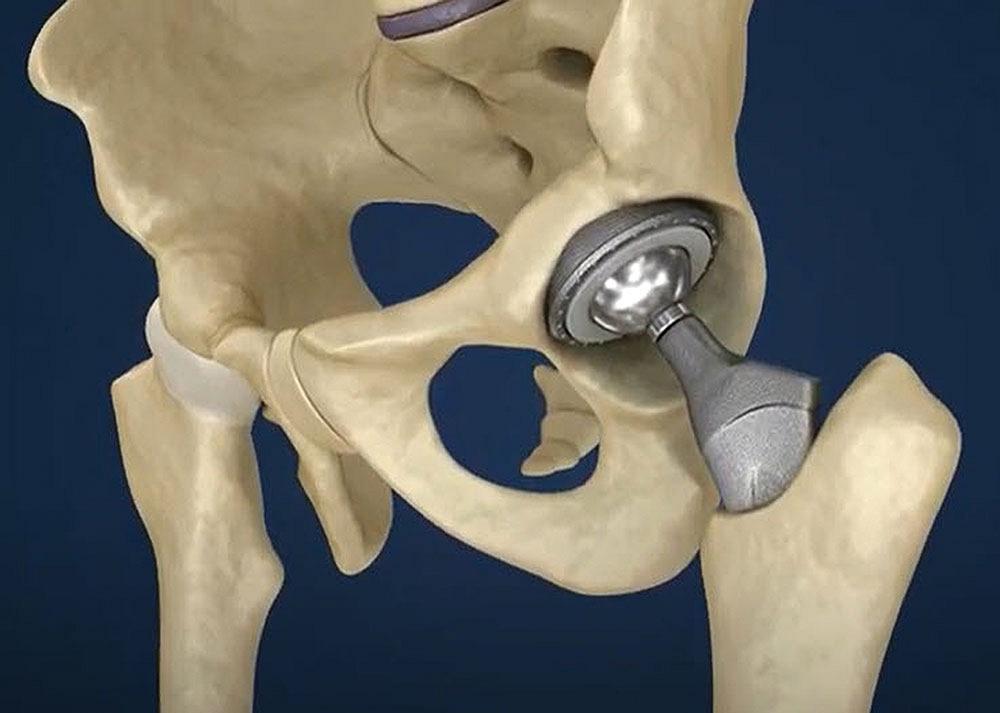

Orthopedic hip surgery numbers are forecast to increase at a rate of five per cent year-to-year until 2026. This is no surprise given the world’s growing aging population.

With this trend, an increased demand for tools and components to support these procedures is emerging. ANCA has produced a machine process for femoral ball grinding, developed together with grinding wheel manufacturer Tyrolit, to deliver quality and consistency in finished femoral balls, using a specialized machine control and new application technology on its MX7 Linear CNC grinding machine.

The medical industry is one in which customers and markets are acutely sensitive to product quality and consistency. This especially is true for orthopedic implants that are placed inside the human body permanently. As a result, customers buying and using orthopedic implants need absolute confidence in the product, which in turn requires absolute confidence in the manufacturing process.

Roundness, Size, Surface Finish

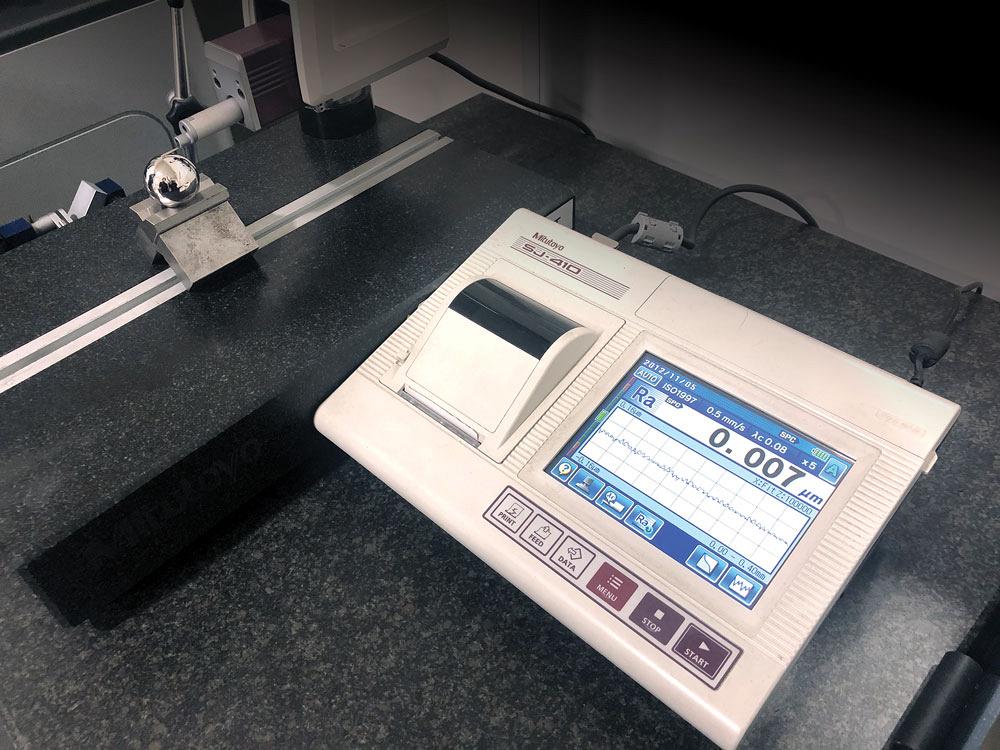

Performance of femoral balls used in hip replacement implants demands consistency of roundness, size, and surface finish as key quality criteria. To achieve this result, ANCA developed a process on its grinding machine that applies a series of sequential grinding, honing, and final buffing operations in the same work envelope. The result is surface finish on the ball of less than 0.01 µm Ra and part roundness under 3 µm.

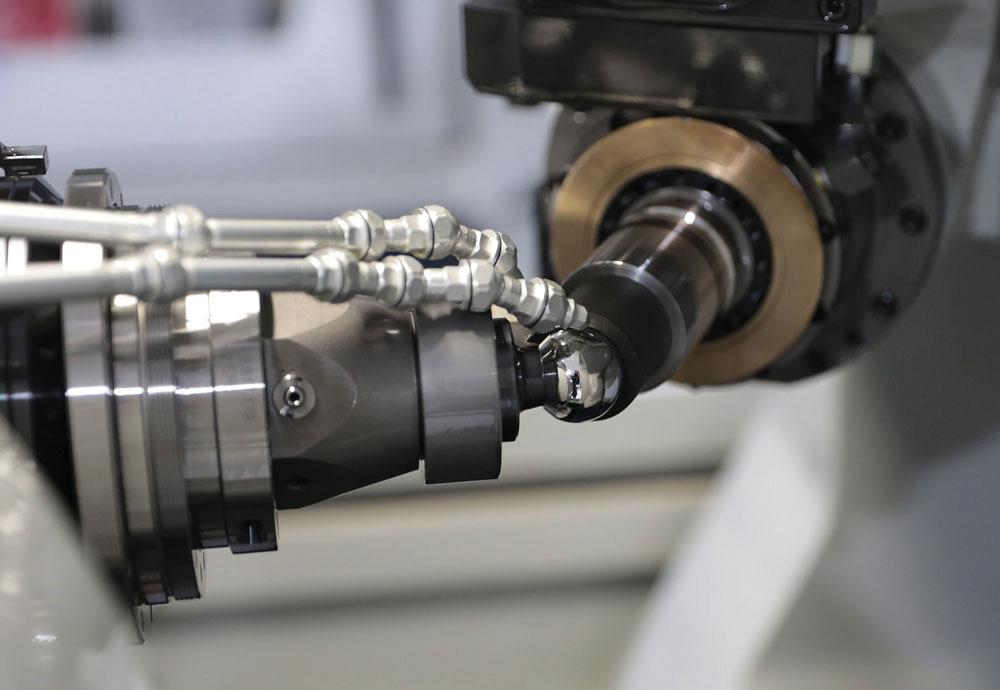

The first step in the process is grinding the initial part accurately to size. Using plated cubic boron nitride (CBN) grinding wheels, excess stock material is removed from the rough-turned part. This operation makes upstream processes easier by relaxing the tolerance demands for the blank part which the machine will grind.

Next are a series of fine honing processes that produce incremental improvement in the surface finish. The company’s application engineers teamed up with their colleagues from Tyrolit to develop a process that delivers stable production results on the femoral ball.

Tyrolit wheels have been developed specifically for femoral ball applications and wear during the production process. As a grinding machine manufacturer, ANCA is well positioned to deal with this challenge, being the designer and manufacturer of its own LinX linear motors as well as the CNC and servo drive system that control the machine and grinding wheel movement.

The company’s system engineers developed an entirely new control algorithm for this application. This allows operators to program the desired forces applied by the honing wheel on the femoral ball. With this programmed force, the wheel feeds into the ball at a constant rate as it wears away. The three different Tyrolit wheels used can be programmed with their own unique grinding force parameter to achieve a mirror surface finish and consistent part size tolerance.

Additionally, automatic wheel measurement helps ensure each honing operation starts from the correct infeed position. This creates consistency in the process regardless of the wheel wear that is experienced after each honing operation.

A final buffing operation is the last step, delivering mirror finish on the working surface of the ball. This is critical to ensure that mechanical friction and wear are minimized in the final hip implant.

This grinding machine has proved to be a suitable machine platform for this application. The six-wheel pack changer helps ensure that all of the grinding, honing, and buffing operations are performed in one setup.

In addition, the tooling used for femoral ball production can be switched over to cutting tool manufacturing applications. As a result, rather than purchasing a dedicated machine for femoral ball production only, shops can use its machine for other CNC grinding applications that complement its market and business model.

Production of surgical rotary cutters, drills, and reamers as well as femoral hip rasps all are suitable applications for production on this machine and will significantly increase presence in the orthopedics market.

ANCA, www.anca.com

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada