Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Innovations, investments, and trends in auto manufacturing

OVIN’s Raed Kadri discusses the current state of auto manufacturing in Canada

- By Lindsay Luminoso

- March 27, 2024

- Article

- Metalworking

There has been a significant shift in automotive manufacturing. Today’s vehicles are not only transitioning to electric, but there also is a push towards connected and autonomous vehicles. Automotive OEMs also have access to a global talent pool that has benefitted research and development efforts and manufacturing capabilities.

Canada, and more specifically Ontario and parts of Quebec, are finding new ways to compete in this global landscape. The skilled workforce, existing infrastructure, and access to critical minerals have given this automotive jurisdiction an edge. However, there is still much more to be done to help boost the auto manufacturing sector elsewhere in Canada.

Raed Kadri, vice-president, strategic initiatives, business development, and head of the Ontario Vehicle Innovation Network (OVIN) at the Ontario Centre of Innovation (OCI), discusses the current state of auto manufacturing in Canada and how innovation, investment, and global trends are shaping its future.

Canadian Metalworking: What is the current state of automotive manufacturing in Canada?

Raed Kadri: Canada, and more specifically Ontario, has been an automotive powerhouse for over a hundred years. We are the only subnational jurisdiction, for many years, that has had five automakers that build cars in our province. And that comes with a pretty hefty supply chain of Tier 1, 2, and 3 suppliers that call Ontario home—whether they'd be homegrown out of Ontario, or they've come to be cemented in our province. It has always been a significant sector for us. That is underlined by the fact that we've created a workforce that is world renowned.

The Toyota manufacturing facility in Cambridge, Ont., is the No. 1 quality-producing facility in the entire Toyota production system. That’s a testament to the workforce in Ontario and Canada. We have an ability to make things and make them very well.

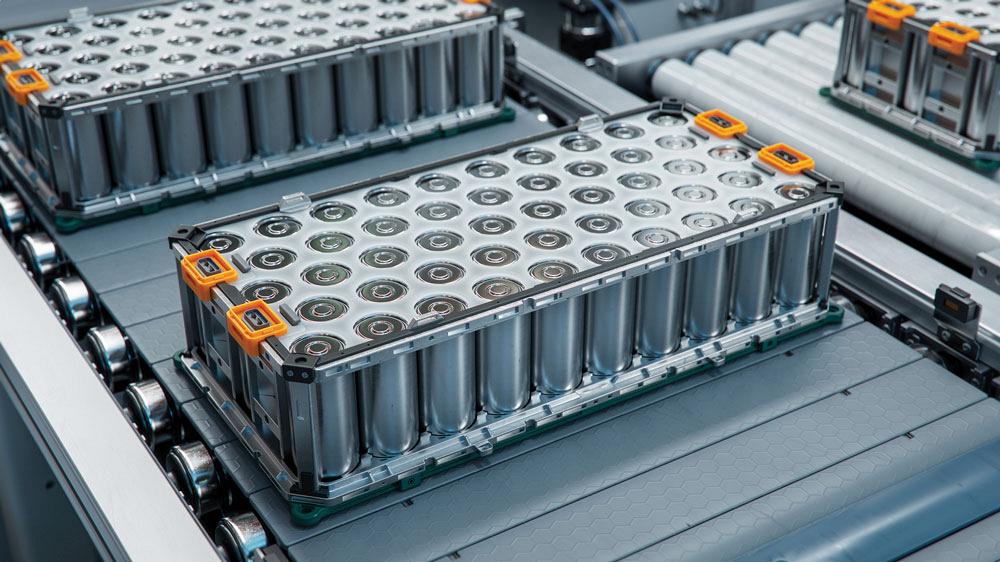

As we look to the future of the auto sector, it’s clear that we’re facing the most significant mobility revolution of our time. Over the past few years, we saw the rise of smart mobility with the growth of connected and autonomous vehicle technologies. And now, we’re going one step further—we’re reimagining how these vehicles are powered. We reached this turning point in 2021, and since then, the entire industry–every major automaker, part supplier, and even new players—has been committed to accelerating the shift to electrification, where the future fuel is battery power.

The next few years will be focused on shoring up where each automaker will build the electric vehicles of the future. At the same time, they'll decide where they'll build the batteries that will power those vehicles—and the choice is clear.

Canada is now No. 1 in the world for battery supply chain. We clinched the top spot in BloombergNEF’s 2024 Global Lithium-Ion Battery Supply Chain Ranking, in large part due to our wealth of critical minerals, strong economic ties with the U.S., and nationwide policy commitments to build a resilient end-to-end battery supply chain.

Ontario has already been the pick of many manufacturers. In the last couple years, we've secured $28 billion in investments in the transition to electric vehicles, like hybrid vehicle production to fully electric vehicle production. Ford is going electric in Ontario. The province is also home to two battery plants. Stellantis is retrofitting and retooling their Brampton and Windsor facilities for electric vehicles. We also have three more automakers that have been here for a long time and will likely be here for a long time. They will be looking at how to transition to electric vehicles in Ontario.

At the same time, there has been a resurgence of interest in connected and autonomous vehicle technology. Once companies chart out their EV path and decide where they are going to make them, there will be a push to try to introduce more technology into the vehicle. It will be a focus on smart electric or zero-emission vehicles. Ontario and Canada are poised to be and continue to be the leader in this space.

We will continue to need [machining and welding] skills but also new ones that come along as the manufacturing processes evolve. – Raed Kadri, Ontario Vehicle Innovation Network

CM: How do Canadian manufacturers keep up with the changing trends?

Kadri: The automakers probably don't do things just on a Canadian level—they think on a global level. But certainly, we're a big part of that global picture. We're second in the world right now in terms of EV and battery investments, which is incredible.

We're not just a global leader in automotive and manufacturing. We're a global leader in information and communication technologies. We are the second largest IT cluster in North America next to Silicon Valley, and we continue to grow rapidly in this space.

Whether it's a big company or small company, we have a highly skilled workforce in the technology space that will contribute to the sector and supply chain.

The auto sector supply chain is no longer just your traditional parts makers like those producing headlights or bumpers, it’s also the people that make the AI algorithm, the infotainment system, and AI assistant.

We've been able to attract so much in investment because we have a skilled workforce to support the industry.

We talk about the quality that we produce in our facilities; making an EV is not going to be much different than making a gas-powered vehicle. It's going to be different components and probably a few different processes.

We have a highly skilled manufacturing workforce, a highly skilled technology workforce, and we continue to push really hard on not only graduating a significant amount of science, technology, engineering, and mathematics graduates from our universities across the province, but also working closely with the auto sector to help with the upskilling and reskilling and other aspects of what we need in terms of the workforce of the future.

When we think of the more traditional skills like machining and welding, those skills are always needed. But they may just be making different things with a different understanding of how to make those things. A vehicle have different components within the vehicle that need to be machined.

We will continue to need those skills but also new ones that come along as the manufacturing processes evolve.

CM: What excites you the most about the future of the Canadian auto sector?

Kadri: We've done an incredible job in Ontario and Canada to attract significant investments. It’s a global competition, and the provincial and federal governments have stepped up and come to the table.

The trends are clear – the automotive sector is going electric. SweetBunFactory/iStock/Getty Images Plus

Any jurisdiction that doesn't have an automotive sector will do almost anything to have an automotive sector. And we [in Ontario] are lucky enough to have and support this industry.

I'm from Windsor, Ont. My dad worked at Windsor Assembly Plant. He made minivans for 30 years. I know what a manufacturing job means to a family. It feeds you, it clothes you, and it educates you. It’s so important to see the value in this industry, and we have done a great job to attract these investments.

The province has put together a plan that is working. We are going to continue to have a great year this year of new investments into our province, which is incredible. We are being methodical about how we ensure we have the right components to support an end-to-end supply chain of EVs.

Are we attracting the investments so the automakers can make the EVs and the batteries in Ontario? Yes. We're putting our best foot forward. We have all the right ingredients. It's a big cost to transition to EVs. But we’ve done our part – we've told our story.

CM: What are the barriers affecting automakers, their suppliers, and even consumers related to the push towards electrification?

Kadri: From a consumer standpoint, one of the biggest challenges is the availability of EVs. In Ontario, we also are making sure that we secure a supply of EVs that consumers can purchase, particularly Canadian-made cars for Canadians.

Once these EV manufacturing facilities get ramped up, that will create more vehicle options and the ability to purchase more vehicles. And with more cars available, we anticipate that the price will become more competitive.The next thing is charging infrastructure. Everybody's got range anxiety. That continues to be a focus for us. The province has a $91 million fund to support increasing the number of public chargers that we have on our roads. The federal government also has a number of programs to support charging stations.

These are proof that Ontario and Canada are focused on laying the groundwork for electrification today, from the vehicle to the grid. We’re supporting the growing adoption of EVs not just by making cars and their batteries, but by building up our grid capacity and ensuring that we can meet the energy demand of future transportation.

CM: What can people anticipate from OVIN in the future?

Kadri: We do an OVIN partnering forum each fall. Last fall, we had a great lineup of speakers. It is a testament to the important role of Ontario and Canada in the global automotive sector.

We had Kazuhiro Doi, the global head of research and development for Nissan, fly from Japan to speak to the audience about trends that Nissan sees and where Nissan is going in the future of the auto sector. We also had Robert Weggässer, senior director of finance and interim CFO of Gigafactory St. Thomas to discuss Volkswagen’s historic $7 billion investment in Ontario and its impact on global battery cell production. Finally, we heard from Marina Krets, director of political operations for Mercedes-Benz, who came from Germany to speak about the company’s EV strategy and how we all fit into the picture.

We had a great lineup of speakers. And in doing this, we are able to bring not just the manufacturing side of it, but the technology, innovation, EV component, connected vehicle component, autonomous vehicle component, and other partners to get together and talk about how we can work together to create made-in-Canada-and-Ontario technologies and potentially spin off some homegrown companies.

Traditional skills like machining and welding will continue to be needed. An EV vehicle will have different pieces that will need to be machined, and they'll have different components within the vehicle that need to be machined. AnnaElizabethPhotography/ iStock/Getty Images Plus

It also provides an opportunity for our local industry to hear from global leaders that see Ontario as a significant and important jurisdiction in their global picture.

Speaking of the global picture, we’re also looking towards the next stage of growth for Ontario-made innovation. We recently launched our Going Global initiative designed to support small- and medium-sized enterprises in expanding their global footprint and facilitate entry into new markets. A key component of this is a strategic partnership with Air Canada, which will allow SMEs to access flight discounts, thus enabling them to connect with global customers and showcase innovative offerings around the world.

We also launched a strategic partnership with e-mobil BW, the innovation agency and competence centre of the state of Baden-Württemberg. This partnership signals our commitment to exchange knowledge and strengthen collaboration between two of the world’s leading automotive and mobility jurisdictions, resulting in further advancing innovation and commercialization of leading-edge technologies and solutions.

These are just some of the most exciting things happening at OVIN, which stem from our mission to catalyze a future that builds safer, cleaner, and more efficient transportation and drive economic development. And as trends are clear that the automotive and mobility sector are going electric, this mission is more important than ever.

Through OVIN, Ontario and Canada are well positioned to lead the charge in this shift. We’re fulfilling our mission by setting the stage for battery manufacturing, starting with unlocking critical minerals in the north. We’re working to attract more investment in connected and autonomous vehicles as well, as a lot of R&D operations take shape. We’re leveraging our significant information and communications technology cluster and building a talented and up-and-coming workforce. We’re bringing all of these strengths together to drive the future. It’s clear that we have a role to play in all of this, and it’s exciting to see the trajectory and where we anticipate ending up.

Ontario Vehicle Innovation Network, www.ovinhub.ca

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI