Head of Business Development

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

New technology makes EDM more flexible

The series is made up of two EDMs: the CUT X 350 and the CUT X 500.

- By Eric Ostini

- January 10, 2024

- Article

- Metalworking

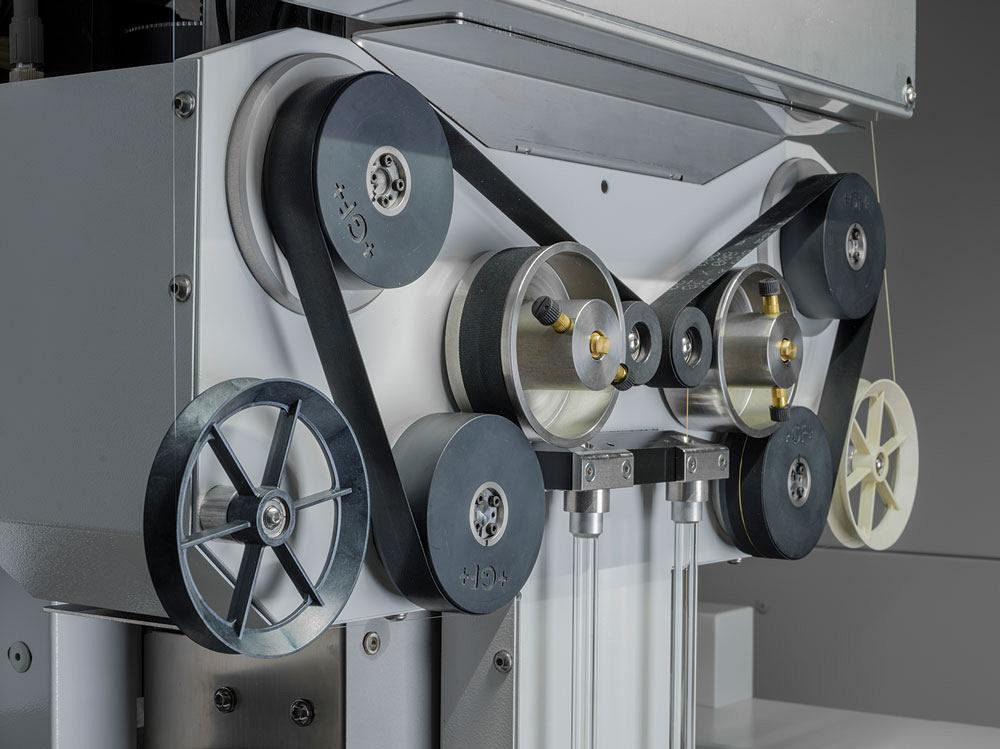

The wire guides enable flexible, continuous production when combined with automatic wire changer (AWC) technology that includes two identical, symmetrical wire circuits. Images: GF Machining Solutions

We all know you should never say never. But there’s never been a one-size-fits-all option in the abundance of wire electrical discharge machining (wire EDM) systems that exist.

Every machine fills a niche or does something a little better than other machines. There’s never been a wire EDM that does everything well. That was the goal behind the creation of the AgieCharmilles CUT X series of wire EDMs.

Developed and manufactured by GF Machining Solutions in its Losone, Switzerland factory, these EDMs come in two sizes: the CUT X 350 (with a maximum workpiece size of 800 by 550 by 250 mm) and the CUT X 500 (with a maximum workpiece size of 1,050 by 700 by 250 mm).

The machines are extremely accurate because of a new thermal management system and optimized mechanics, which also help improve surface quality. Consistent thermal conditions are maintained by using sealed cabinet and doors that ensure cold air containment within the workspace as well as controlled air flow. By keeping heat sources away from the machine’s mechanics, these machines perform consistently without the ill effects of temperature fluctuation outside the machine.

AI Algorithm Predicts Deformation

The machine’s CNC collects data from an array of temperature and humidity sensors located inside and outside of the work area to further maintain ambient workspace conditions. That data drives an artificial intelligence (AI) algorithm that predicts possible thermal deformations and compensates the positioning of the X, Y, U, and V axes. This AI-driven compensation enables high accuracy even with the environmental temperature fluctuations that are common during long cutting cycles.

These EDMs also have the ability to switch between open and closed wire guides—sometimes known as V and round guides, respectively—on the same machine.

The wire guides have interchangeable cartridges that can be switched by the operator in less than 15 minutes (five minutes to change the cartridge and 10 minutes to align the wire circuit).

Open guides are suitable for straight or less than three-degree taper angle cuts and provide flexibility for varying wire diameters without changing the guide. Closed guides provide high accuracy, speed, and surface finish for taper cuts up to 30 degrees.

Increased EDM Cutting Speed

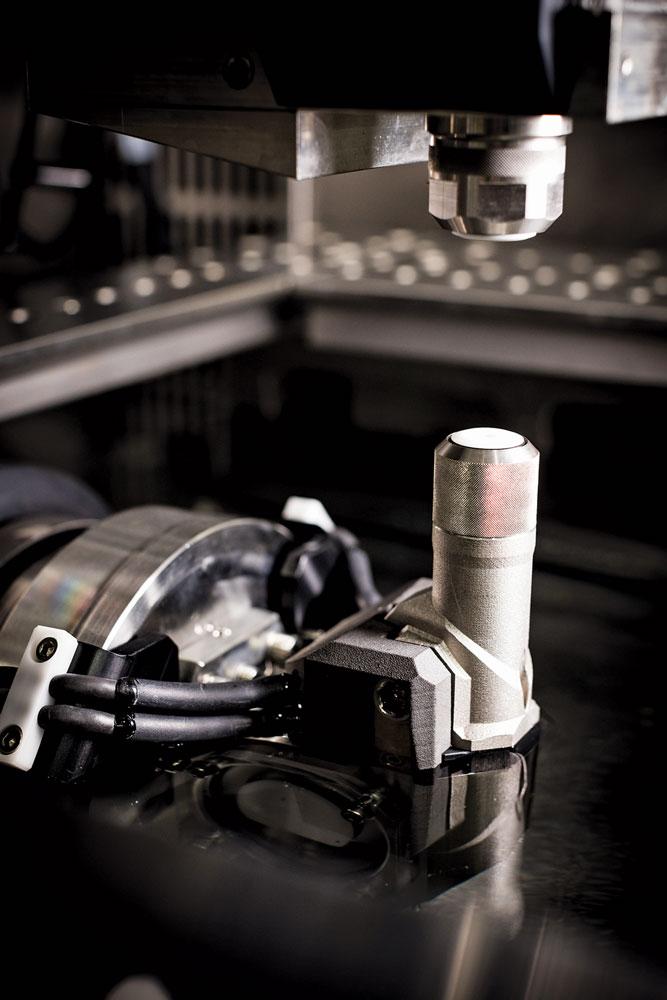

New additively manufactured upper and lower heads increase the cutting speeds of these machines. The heads reduce the distance between the guides and the part, creating better accuracy during the cut, while also increasing the amount of fluid that is pushed through to optimize the flushing channels and increasing cutting speeds.

Advanced software accessed by the operator through the Uniqua human-machine interface (HMI) is used to set the necessary power settings to achieve the desired result. The machines’ Intelligent Power Generators with Direct Power Supplies (IPG-DPS) dial in the correct power settings with algorithms based on decades of work by GF Machining Solutions for development of specified surface finishes and accuracies at specific speeds.

These EDMs have the ability to switch between open and closed wire guides—sometimes known as V and round guides, respectively—on the same machine.

The HMI has a 19-in. vertical touch screen and a full keyboard and mouse. The control supports legacy file types from various older Charmilles (ISO-based) and Agie (dynamic-based) EDM programs. The interface also has a graphics tool for programming both off-line and at the machine that is compatible with major CAD/CAM programs.

In addition to the series’ cartridge-based wire guides, flexibility and continuous production is gained with the incorporation of automatic wire changer (AWC) technology that includes two identical, symmetrical wire circuits. With this AWC, operators can use a thicker wire for a fast, aggressive main cut followed by a thinner wire to trim-cut small corner contours. The technology also enables the use of two wires of identical diameter, with and without coating, to optimize speed during the main cut and surface finish during the trim cut.

To prevent wire breakage, the system uses Spark Track technology and Intelligent Spark Protection System (ISPS) to constantly monitor and evaluate the position of each discharge between the wire and workpiece in real time against set thresholds. If the discharge concentration exceeds the threshold, ISPS automatically adjusts the spark energy for optimal wire condition and cutting speed.

These machines have 90-degree corner doors that automatically open for operator entry to the entire work area. The doors also enable robotic loading/unloading. Further lights-out productivity is possible thanks to the integrated Z-axis touch probe that automatically measures the top surface of the workpiece and aligns the wire perpendicular to this new plane and an automatic slug management system that removes slugs to a dedicated bin. Wire management is also automated for autonomous operation with automatic wire threading, an integrated wire chopper that reduces downtime, and a double-wire spool with AWC technology.

Eric Ostini is head of business development at GF Machining Solutions 41 Keyes Ct. Unit 1, Woodbridge, Ont. L4H 0W6, 905-565-6942, www.gfms.com.

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI