- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Technology Spotlight: Compensating chuck technology

Fixed centre housing, carbide dead centre combine to hold tight cylindrical grinding tolerances

- By Canadian Metalworking

- February 19, 2018

- Article

- Metalworking

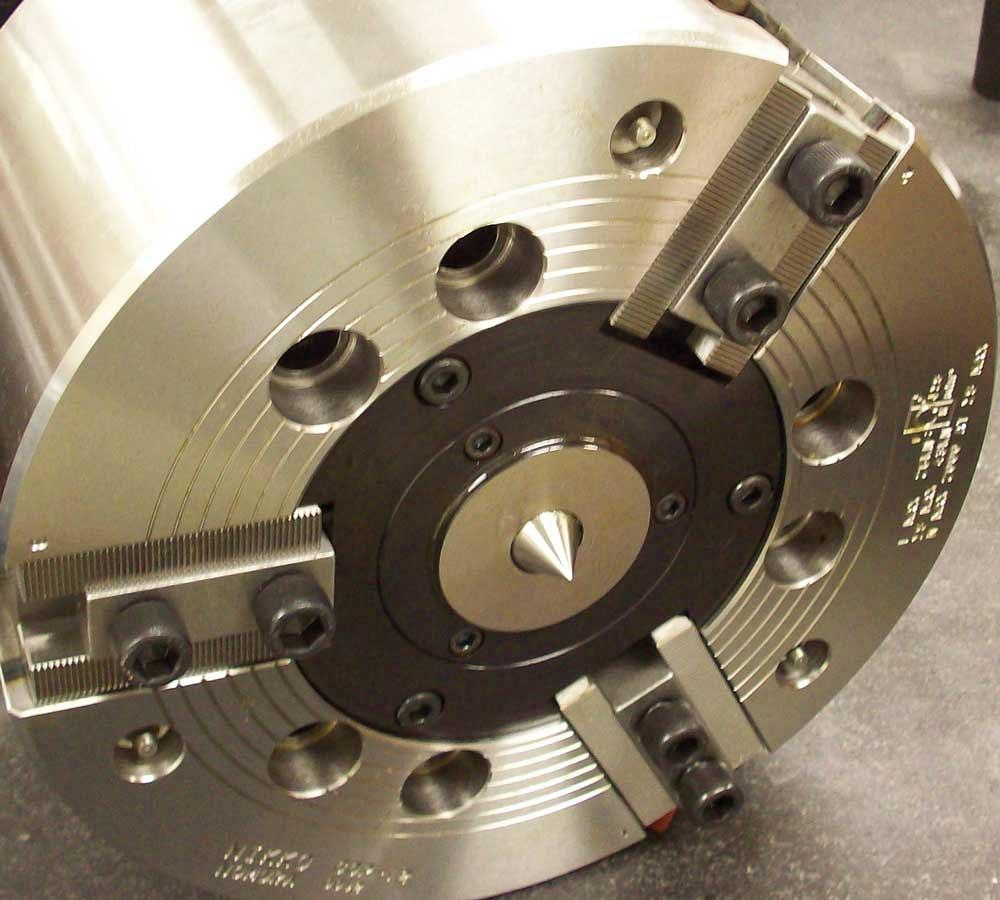

Compensating jaw chucks, common in turning applications, now can be used to drive parts between centres during grinding. Image courtesy of Powerhold.

Cylindrical grinding between centres can be cumbersome when the part has no feature that can be used for driving. It gets even more challenging if the goal is to automate the grind cell with an automatic loader.

Powerhold, Middlefield, Conn., has developed a process for customers using a compensating jaw chuck to drive the part between centres for grinding. Compensating jaw chucks often are used for turning work on shafts and rifle barrels, but are not commonly used for cylindrical grinding. A typical compensating jaw chuck has a spring-loaded centrepoint that locates the part against a chuck-mounted part rest and either two or three jaws that are connected on a swivel internal to the chuck so that they can clamp on a surface that is not concentric to the locating centre.

On a typical 7-in. chuck, the part grip surface can be out-of-round as much as 4 mm to the locating centre. Each jaw contacts the part individually, and the swivel self-aligns so that the drawbar pull force is equal on all the jaws even though they are not centreing the part.

Retrofit Chucks

To get the proper results for grinding, the company retrofits the chuck with a fixed centre housing with a high-accuracy carbide dead centre.

Special top jaws minimize lift of the part off the centrepoint. A custom-made part rest also is supplied on the chuck face. Centrepoints can be standard 60-degree tips, special sizes, female style, or bullnose, depending on what is required. Tailstock force is required to hold the part on the chuck centrepoint, and it must be kept low, especially on small parts that could deflect under higher tailstock forces.

Centre quality on the workpiece is critical to getting good results. The repeatability of the grind process will only be as good as the centres on each end of the workpiece.

Part cylindrically ground to better than 50 millionths is achievable with this setup, the company states. Because there is no drive dog or drive pin, a robot can load the parts into the chuck with no concern for orientation. Jaw stroke is typically 8 mm or more per jaw on these chucks, so there is no concern for tight fit or load clearance with the robotics, as opposed to compensating collet chucks which have much smaller load clearance. An air actuator is often part of the complete grinder spindle package, allowing the operator to tune the clamp force to the application requirement.

Chucks, centrepoints and centre housings, part rests, spindle adapters, draw tube connections, and air cylinders all are available grind applications. The most common chuck size is 7 in. but the chucks come in 8 and 12 in. sizes for larger parts if required.

Powerhold, www.powerholdinc.com

About the Author

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

Mitutoyo updates its end-user portal

Enhance surface finish with high-speed machining

Equispheres secures $20 million investment round

Solid carbide drills produce precision holes in short chipping materials

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada