- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Training Profile: George Brown College

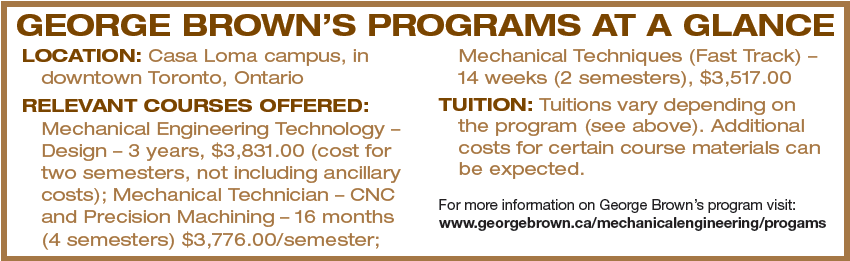

The Casa Loma campus in Toronto’s downtown core is home to the school’s Construction and Engineering Technologies program, which encompasses the school’s metalworking-specific courses.

- By Canadian Metalworking

- July 3, 2014

- Article

- Metalworking

George Brown, located in the heart of Canada’s largest city, offers a slew of college courses to students, and metalworking and engineering diploma programs are a major part of that.

The Casa Loma campus in Toronto’s downtown core is home to the school’s Construction and Engineering Technologies program, which encompasses the school’s metalworking-specific courses.

Ylber Ramadani, one of the chairs at the school, spoke about some of the opportunities for potential students of George Brown. “We’ve recently changed the scope of our tool and die program, because tool and die doesn’t have the appeal it once used to,” Ramadani says.

“(The) curriculum has changed, but nobody thought to change the name. CNC and Precision Machining is the official name – that will be launching in September.”

Ramadani has a background in electronic engineering, and began teaching at the school in 1999. Since then, he’s seen a number of changes in manufacturing in this country, and emphasizes the need for teaching practices to keep pace.

“It’s about telling everybody about what we do,” he says, “We have more CNC (computer numerical control), more MasterCam, and a lot more digital stuff than traditional machining.”

However, Ramadani is careful to point out that the basis for the program starts with the fundamentals.

“But we start in a machine shop. Everything starts there — you have to understand what we’re doing.”

George Brown also takes a comprehensive approach to teaching. While there are various streams a student can follow, they get a foundation in a lot of different fields.

“We expose them to machining in general, traditional machining. We expose them to basic electronics, circuits, basic drawing, engineering drawings. The curriculum is

streamlined.

“So what happens is, you start mechanical engineering, and you find this may not be what you have actually dreamt of doing...we’re seeing lots of shifts in programs after the first semester without any penalty to students.”

Also, the mechanical engineering and precision machining programs now have the entire first year in common, making the early stages of that program much more in sync than it previously was. This opens a lot of doors for students to find out what they’re good at, and follow through on that. If a student is more mathematically inclined, they may seek to find a more engineering-heavy program or maybe the student enjoys working with equipment, and sees a better fit in a shop floor setting.

George Brown is also planning to adapt as manufacturing changes. The school is considering adding courses in rapid prototyping (3D printing) in the future, and also is in the process of trying to get the necessary accreditation to have some of their diploma programs become degree programs, which would give students greater opportunities upon graduation.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI