- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Windfall in wind energy?

Gear and gearbox production, repair, maintenance keep wind energy projects strong

- By Nate Hendley

- April 1, 2020

- Article

- Metalworking

A worker performs uptower field service by reinstalling a nacelle's roof. Photo courtesy of Moventas Gears Canada.

Despite political turbulence, Canada’s wind energy sector continues to gain strength, offering many opportunities for machine shops. To enter the wind energy supply chain, however, it helps to be fast, nimble, and capable of handling really big parts.

Installed wind energy capacity in Canada climbed to 12,816 MW in 2018 from 2,349 MW in 2008, enough to power approximately 3.3 million homes, according to the Canadian Wind Energy Association (CanWEA).

As of December 2018, there were 299 wind farms and 6,596 wind turbines in Canada, most of which have gearboxes (used to boost blade rotational power). Gears and gearboxes require parts and service, which is where machine shops come in.

Serving the wind sector

In Delta, B.C., Ideal Gear & Machine Works designs, manufactures, and refurbishes gears and assembles gearboxes for the forestry, mining, oil and gas, and power generation industries. The ISO 9001:2015-certified shop counts wind turbine gears as one if its niche specialties.

While there’s a lull in wind gearbox work at Ideal right now, the firm’s experience puts it in a good position for future assignments.

“Ideal Gear has made gearing for wind energy OEMs. In some cases, we made new parts for their product, and other times we would regrind existing gearing that is reused in their own rebuilds,” said Ideal Gear President Jim Mantei.

Such work is par for the course in the Canadian wind sector because there is no such thing as mass production of wind turbine gearboxes here.

“I do know a number of shops that are either [doing] refurbishing or up-engineering work,” explained Phil McKay, operations and maintenance program director at CanWEA.

Gearboxes are supposed to last the lifetime of the turbine, which is 20 to 30 years, he explained. While in service, gearboxes require upkeep and, sometimes, parts and repairs. Machine shops are often called upon to engineer a part to replace a bad bearing, gear tooth, or casting.

Working with wind gears and gearboxes presents some unique challenges.

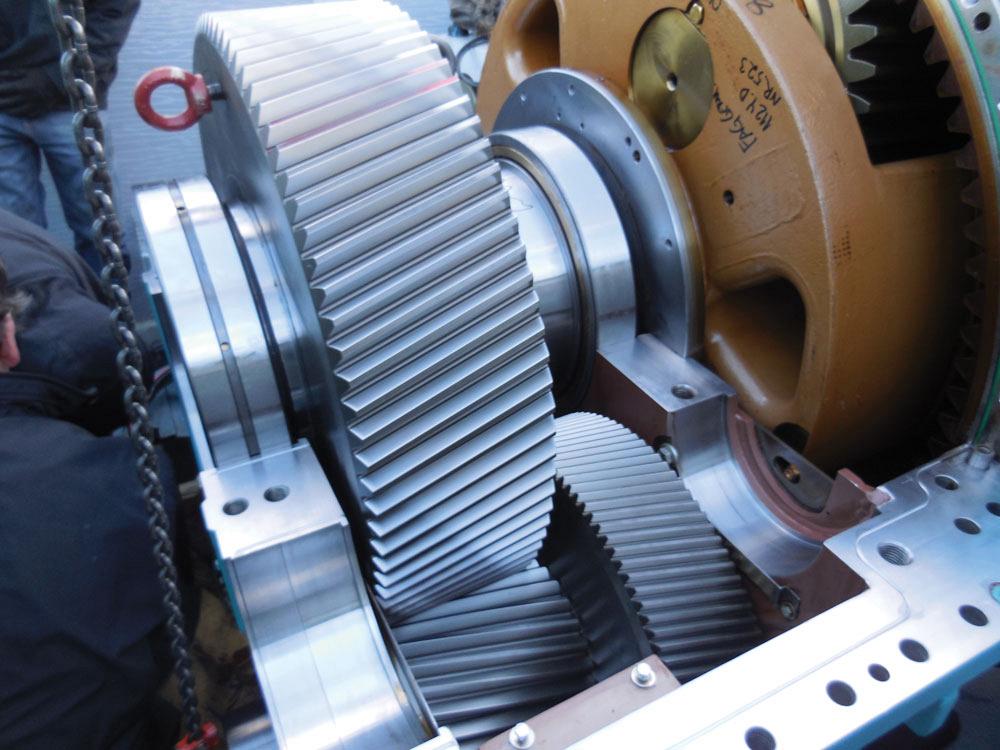

An uptower repair of a gear unit takes place high above the ground. Photo courtesy of Moventas Gears Canada.

“Wind turbine gears require extreme accuracy and gear tooth grinding with special tooth modifications. With our modern CNC gear grinders, we are able to provide the highest AGAM [American Gear Manufacturers Association] quality levels,” said Mantei. “Some wind turbine gearboxes are very large and require very accurate machining capabilities to maintain the very tight tolerances required to ensure proper alignment between the mating pinions and gears.”

Repair and rebuild

Accu Electric Motors, an ISO 9001-certified shop in Oakville, Ont., repairs and rebuilds gearboxes and other equipment for a variety of sectors, including power, automotive, agricultural, and wind.

Most of the company’s wind gearbox work involves general overhauls.

“This includes work like bearing change, seal change, and [repairing] a worn shaft,” said Daman Bajwa, an electrical engineer at the company.

For wind turbine shaft repairs, Accu Electric uses an industrial lathe. Removing shafts can be difficult, given how compacted all the internal components of wind turbine gearboxes are, said Bajwa.

Still, he added that repairing and rebuilding wind turbine gearboxes isn’t that far removed from fixing gearboxes in robotic systems used for automotive manufacturing.

“They are all pretty much planetary gearboxes at the end of the day. Size is the biggest factor,” he said.

Large-part manufacturing

Scott Clark, sales director for Canada, Moventas Gears Canada, Cambridge, Ont., a branch of Finland-based wind turbine gearbox manufacturer Moventas, helps puts the size in perspective.

“Our components weigh 5,000 to 6,000 lbs. A whole gearbox is 40,000 lbs. Usually the limiting criteria [for subcontractors] is that they don’t have a machine big enough to machine what we need,” said Clark.

The Moventas parent company makes gearboxes for wind turbine OEMs such as Acciona Energy, Vestas, GE Renewable Energy, NEG Micon, Siemens Gamesa, and Senvion. Manufacturing is done in Finland. While Moventas Gears Canada sometimes assembles small numbers of gearboxes, the firm is mostly focused on repairs, rebuilds, parts, and maintenance.

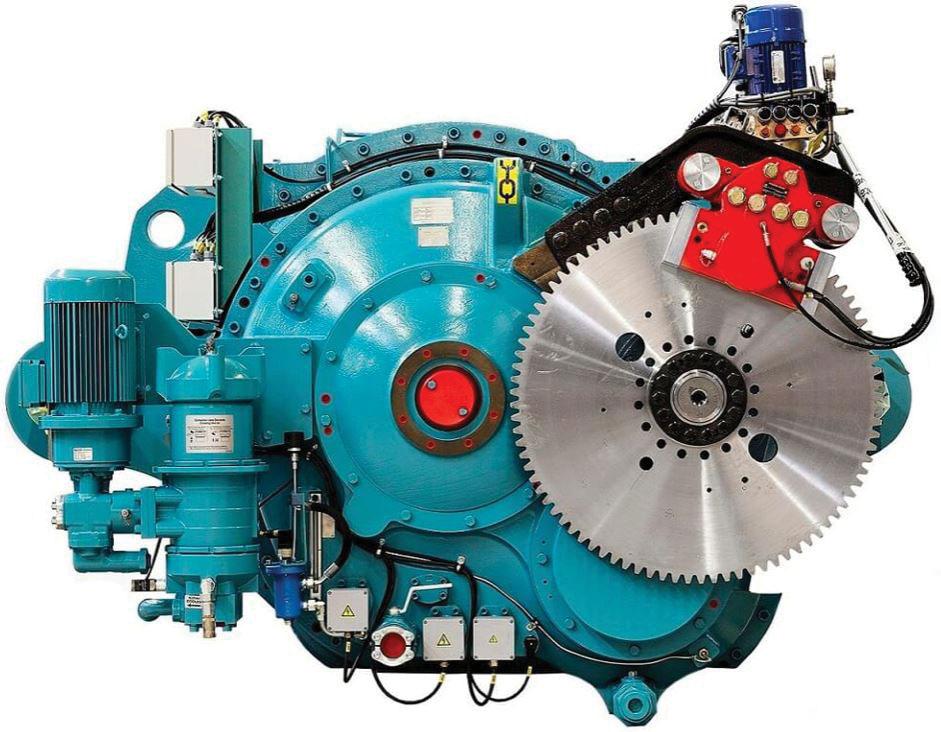

This fully assembled gear box is ready for shipping and installation in a wind tower project. Photo courtesy of Moventas Gears Canada.

“We have the capacity to bring components from Finland and build a brand-new gearbox as a capital assembly. We have had opportunities to outsource some components and gear manufacturing locally for smaller projects; however, our core business in North America is multibrand service and spare parts,” he explained.

Moventas Gears Canada moved into a new facility in late 2019, doubling in size to 25,000 sq. ft. There are no plans to use the new space for mass gearbox production. The firm does, however, hire subcontractors for repair and rebuild work.

“When a gearbox comes into our shop, we do a complete tear-down. Every nut and bolt is taken apart. We do a complete report, then we ship it out to our subcontractor and have them machine it or laser-clad a surface or regrind gears for us. We also ship the components individually. Shipping a whole gearbox is costly, and not everyone has the capacity to handle a whole gearbox,” said Clark.

The company sometimes uses machine shops to load-test rebuilt gear units, and the company does quite a bit of outsourcing of smaller components. For example, a lot of hoses are built locally because it’s easier than trying to order them from overseas.

Moventas Gears Canada also always looks for opportunities to lower its costs to produce by using local resources, added Clark.

Keeping its business local means Moventas can keep a close watch on work at hand and save on shipping costs, he explained. The company also likes shops that are capable of speedy turnarounds.

For its part, Moventas Gears Canada doesn’t insist on ISO certification, but does set high standards for shops looking for work.

The company audits all potential partners.

“We make sure they have the proper quality control and that kind of thing. We wouldn’t send out complex equipment to just anybody. We do our due diligence on these shops,” said Clark.

Know the market

CanWEA’s McKay advises shops that are interested in wind sector work to become familiar with the brands in the market. Other wind turbine gearbox manufacturers besides Moventas include ZF Wind Power of Belgium, Winergy of Germany, Ishibashi Manufacturing of Japan, and Siemens Gamesa Renewable Energy in Spain.

A main bearing is repaired and then the bearing housing is reassembled onto the shaft. Photo courtesy of Moventas Gears Canada.

As for the kind of equipment and applications required for wind gear and gearbox work, Mantei offers a list.

“We can cut gears up to 3 metres in diameter on our large Gleason-Pfauter P2800H CNC hobbing machine and grind gears up to 1.5 m in diameter. For turning, we have a number of newer CNC machine tools including an Okuma Multus B750 5-axis machine with skiving and hobbing capabilities and it has just over 1 m turning diameter by 3.5 m length. Our largest turning machine is a Toshiba TSS-C vertical turning lathe with up to 5-m diameter with live tooling capabilities. For gearbox machining, our largest machine is a Doosan DBC-110 CNC horizontal boring mill that’s 4 m long by 2.5 m wide,” he said.

Still, wind energy is still a pretty small sector compared to automotive or aerospace. While expanding, the wind sector is vulnerable to market swings and political headwinds.

Last summer Alberta’s newly elected United Conservative Party (UCP) cancelled the Alberta Renewable Electricity Program (REP), which would have ensured that 30 per cent of the province’s electricity was generated using renewable sources by 2030. UCP says it will honour existing REP contracts.

The new Progressive Conservative government in Ontario, meanwhile, cancelled dozens of renewable energy contracts after coming to power in 2018 and repealed the province’s Green Energy Act.

Such developments in Ontario “have shaken up investor confidence in the province. It’s certainly something that will impact the industry going forward,” said McKay.

McKay remains optimistic, pointing out that Ontario still has the largest wind energy sector in the country, with approximately 40 per cent of Canada’s total installed capacity. According to CanWEA, wind met roughly 8 per cent of Ontario’s electrical demand in 2018. Once all the numbers are crunched, the organization expects similar results for 2019. Quebec currently has the second-largest wind energy sector in Canada, with roughly 30 per cent of total installed capacity while Alberta has the third-largest capacity (despite UCP’s actions). Wind energy also has a strong presence in B.C., Nova Scotia, and New Brunswick.

The future

Two main factors are driving the wind sector’s ascent: environmental concerns and decreased costs. The cost of wind energy has dropped nearly 70 per cent in the past decade, to the point where it can claim the lowest costs of any new electricity generation in the country, according to McKay.

Wind power has been the leading source of new electricity generation in Canada for the past decade, with installed capacity increasing at a rate of 20 per cent a year, reports CanWEA.

Market researchers predict a huge rise in the popularity of wind energy and an ensuing demand for gearboxes.

According to the report “Wind Turbine Gearbox Market 2019 Global Industry Outlook to 2025 Research Report” from Market Research Future, the global wind turbine gearbox market is poised to touch a valuation of US$8.63 billion by 2025. It cites awareness of renewable sources of energy and rapid depletion of fossil fuels as reasons that wind energy is a very lucrative investment market. It adds that the reduction in wind power generation costs can contribute to market revenues for years to come.

“I see the Western provinces like Alberta and Saskatchewan are poised for growth in wind over the next five to 10 years, and that is a positive for Canada and Moventas moving forward,” said Clark.

McKay believes the wind energy sector is capable of adding capacity of a gigawatt a year into the near future.

“As we see more electric vehicles plugging in, as industry shifts from gas power and fossil fuel power to more renewable sources of energy for their processes and manufacturing, I think that demand will go up and wind will be seen as an option that is quite affordable,” said McKay.

Back in B.C., Mantei says much the same.

“With today’s focus on alternate and green energy solutions, we expect the wind energy markets will be an area of future growth,” he said.

Contributing writer Nate Hendley can be reached at nhendley@sympatico.ca.

Accu Electric Motor, accuglobal.com

CanWEA, www.canwea.ca

Ideal Gear & Machine Works, www.idealgearworks.com

Moventas Gears Canada, www.moventas.com

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI