Director of Marketing

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

10 reasons manufacturers need software and technology

Collecting and using manufacturing data leads to shorter lead times, increased profits

- By Adam Grabowski

- October 8, 2019

Efficient, accurate scheduling lets shop owners deliver on time, manage change, and uphold promises to customers.

Technology affects every part of our day. Typically, we see technology as a means of entertainment, but as more high-tech devices enter the manufacturing workplace, software and IT are becoming commonplace, and even necessary.

The introduction of high levels of manufacturing software technology can affect a manufacturing business in many ways. These are the top 10.

1. Move parts through the shop faster.When you get parts through the plant faster, customers will order more, and your shop will be more profitable. Schedules always are efficient and accurate, because they are based on a shop’s true capacity. Machinists always know what to work on now and what’s next. They also instantly know the status of all jobs in real time. This, in part, allows them to correct part quality issues in real time instead of afterwards.

2. Maintain accurate inventory.Knowing jobs are never late from lack of materials or more expensive than they should be reduces risk. Some software enables shop managers to know exactly what is in inventory and where it’s located. Precise inventory management looks like the following:

- Lot bin tracking enables complete traceability of parts.

- Physical inventory counts are fast and accurate.

- Bar coding all material lets you know exactly what you have in inventory and where it is.

- Rarely need to pay expedited shipping charges for incoming material.

- Jobs are never late because of the lack of raw materials.

Efficient, accurate scheduling lets shop owners deliver on time, manage change, and uphold promises to customers.

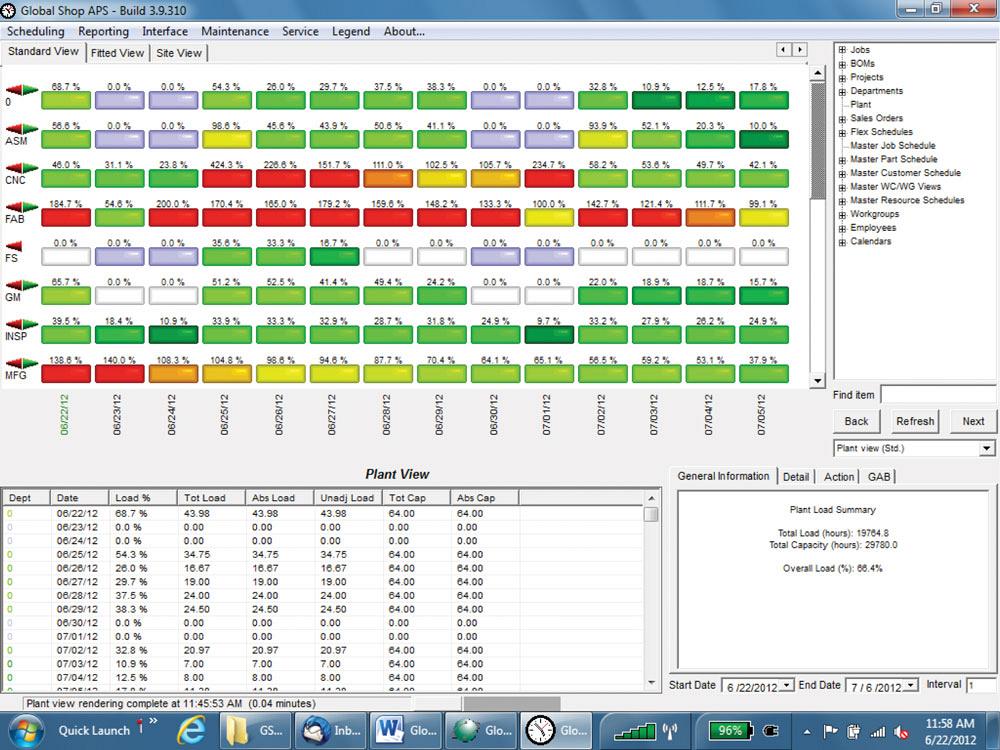

Using the correct software allows managers to correctly estimate lead times, know the true capacity for machines and personnel, and identify production bottlenecks in real time.

Knowing the status of all jobs in real time allows schedulers to instantly see how inserting a job into the schedule will affect other jobs.

4. Control labour costs.With enterprise resource planning (ERP) software, shop floor operators can log on and off jobs and job sequences without leaving their workstations. Collecting time and performance metrics becomes fast, efficient, and accurate, which reduces labour costs.

These software systems track labour down to the minute for jobs and job sequences and, therefore, hold operators accountable for their time. The software tracks the number of hours for each job precisely.

It also minimizes overtime.

5. Achieve 99 per cent quality rating.Consistent, near-perfect quality makes it easier to win more jobs and earn and maintain ISO and other quality certifications. When ERP and other software is used, engineers and machinists always work off the correct document versions.

Bad parts are identified as they are made (rather than during or after shipping). This allows the quality department to document cause and take corrective actions quickly. Tracing every part with 100 per cent accuracy as it moves through your shop floor also is possible.

The last quality benefit is that it becomes easier to produce quality documentation for ISO and other compliance auditors.

6. Give great customer service.ERP lets you go beyond merely upholding promises and stay one step ahead by anticipating customer needs and having all the information you need when they ask.

From purchase order history to WIP, the software enables workers to drill down into any information about a customer from a single screen. It even can automatically alert you or your customer when critical events happen.

Customers also no longer have to wait for answers because employees have access to all the information they need in one system. They can even get answers to questions about orders (such as WIP or shipping status) from a mobile app.

7. Grow sales.ERP software provides a hidden return: sales growth from delivering a quality part on time every time and knowing your bids are competitive, profitable, and margin-true.

Sales orders are accepted, and work orders can be sent to the shop floor within minutes.

The software also makes quoting and estimating easier because job costs and margins are easily tracked.

8. Gain competitive edge.ERP technology lets machines, systems, and devices do much of the work employees used to, allowing them to focus on decisions, thinking, and improving the business. Customization of the system tailors to each manufacturing environment.

Having TVs throughout the shop floor broadcasting job status in real time and what to work on next is one part of the system that enables a shop to work smarter. Using tablets at each workstation makes collecting labour data easier and more accurate.

It’s important, however, to have all systems, from expense collection to machines and tooling, integrated with the ERP software. This makes it possible to eliminate manual spreadsheets used to store data because everything is in the ERP system.

9. Know job costs.When you can trust your costing process, you know how much each job costs. Fast quoting and accurate pricing bring in new customers and retain existing ones. Benefits of knowing true job costs include:

- Tracking direct labour for each job and job sequence down to the penny.

- Tracking material costs in real time as jobs move through production.

- Comparing actual versus estimated costs while the job is in progress.

- Knowing exactly what is in inventory and what it cost.

- Knowing margins are correct by knowing the true costs.

Decisions are better and can be managed proactively based on data you can trust to be true. Knowing right away when something critical happens in the business, like a new deal, completed shipment, or payment of an outstanding account, is important in today’s ever-changing business environment.

Adam Grabowski is director of marketing for Global Shop Solutions, 975 Evergreen Circle, The Woodlands, Texas 77380, 800-364-5958, www.globalshopsolutions.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

GF Machining Solutions names managing director and head of market region North and Central Americas

Mitutoyo updates its end-user portal

Enhance surface finish with high-speed machining

- Industry Events

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada