Founder/CEO

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

How to perform (and judge) a maintenance audit

A robust audit plan creates recommendations for better productivity and business success

- By Bryan Christiansen

- December 6, 2022

How organized is your facility maintenance program? Are your corrective and restorative measures contributing to better asset effectiveness? Maintenance audits provide comprehensive answers to these questions.

Disregarding maintenance audits has several risks. Your company spends more money and time maintaining assets, yet the productivity of various assets remains unsatisfactory.

A maintenance audit is a strategic process for reviewing the reliability of established maintenance programs, work tools, spare parts, and personnel. During the process, you create a comprehensive list of standards that workers must adhere to and evaluate the level of compliance over time.

Companies use maintenance audits to unearth shortcomings in established standard operating procedures (SOP), operational bottlenecks, and other maintenance-related problems. Companies use insights from these audits to create mitigation measures and eliminate any issues that may impede maintenance workflows or affect the overall quality of maintenance tasks.

When conducting maintenance audits, you should evaluate:

- The effectiveness of existing maintenance plans

- Safety awareness among maintenance staff

- Data management standards

- Maintenance budgets and inventories

- Employee technical capabilities (training standards)

- Quality of maintenance work based on maintenance metrics

Companies typically conduct maintenance audits based on the success of existing maintenance programs. Other audits are conducted within fixed timelines as specified by regulatory or governmental authorities. These can be conducted internally or by enlisting the services of accredited third-party organizations.

Organizations with good safety standards protect the lives of employees, physical assets, and customers.

Here is how to conduct and judge a maintenance audit and enhance the objectivity and reliability of your maintenance strategies.

Types of Maintenance Audits

Maintenance audits are used to improve internal processes or are a mandatory requirement to operate in specific localities. Companies also can receive certifications for passing audits. So what are the different types of maintenance audits, and how are they structured?

1. Voluntary audits.

A voluntary maintenance audit is an internally initiated program that you can use to streamline processes and enhance your competitiveness. You are not under any obligation to perform these audits. When performing these audits, you specify the codes, policies, and performance indicators to examine. The audit team inspects all the procedures, assets, and personnel against the prescribed codes or standards and awards points for each audit category.

The frequency of these audits depends on the existing shortcomings and emerging operational challenges. The goal is to ensure maintenance teams record significant improvements after every audit cycle. The cycle could be quarterly, semi-annually, or annually.

2. Mandatory audits

Some organizations are required by law to perform regular maintenance audits because of the nature of their operations. These audits follow a stringent template and seek to ensure all codes and policies are being followed. Failure to pass this type of audit implies the end products are not to spec.

Submitting maintenance audits to the relevant authorities proves your commitment to establishing operational best practices per the industry’s standards.

Judging Maintenance Audits

Performing a maintenance audit may sound tedious and resource intensive. However, with the correct data and benchmarks, audits can be completed within a short time without affecting routine workflows.

You begin by creating a comprehensive list and categorization of all production assets within a facility and a summary of all scheduled maintenance activities. You need to establish objectives based on the current maintenance strategy, which could be a reactive, preventive, or proactive maintenance strategy.

An organized maintenance department keeps a detailed record of all maintenance interventions. They also have SOPs that technicians must adhere to when conducting and recording both scheduled and emergency maintenance. Maintenance teams also should keep track of critical performance metrics for each piece of equipment. These metrics can include:

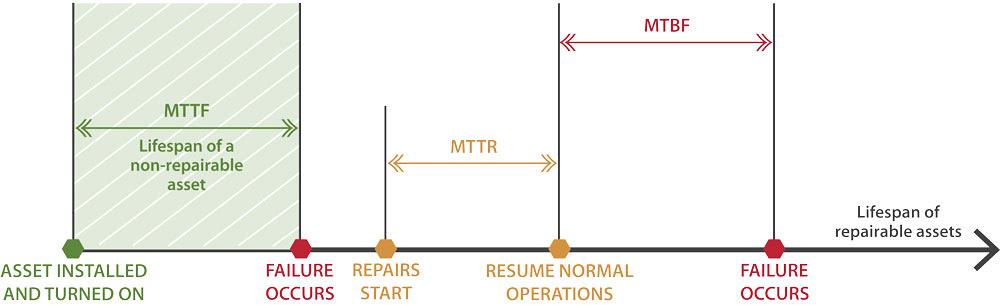

- Mean time between failures (MTBF). This is an availability and reliability metric. It helps detect how long a piece of equipment can stay running between unplanned breakdowns within a certain period of time.

- Mean time to repair (MTTR). This metric is used to measure the amount of time it takes to repair a piece of equipment. It affects equipment availability.

- Mean time to failure (MTTF). This is a reliability metric used to measure how long an item is expected to last before it needs to be replaced. It helps estimate the lifespan of unrepairable products.

Using a computerized maintenance management system (CMMS) to automate maintenance helps enable companies to centralize the data required to perform a comprehensive audit. A CMMS summarizes massive amounts of data and provides insights into the nature, cause, and propagation of specific asset failures.

Companies can use it to compare computer-generated metrics against predefined benchmarks. The auditing team can pinpoint operational bottlenecks and specify if the existing SOPs are effective. They also evaluate the relevance of maintenance technologies amid emerging digital asset management trends.

A successful maintenance audit provides a comprehensive list of recommendations to improve the schedule and quality of maintenance activities. These recommendations act as benchmarks when planning subsequent audits. Sharing audit results across all departments ensures everyone plays their part effectively and participates in improvement initiatives.

Companies benefit significantly from regular maintenance audits because they use past maintenance data and incident logs as reference points to initiate audits.

You should formulate audit objectives based on approved industry codes and standards.

Leveraging digital technology for maintenance audits guarantees access to vast amounts of data. It improves the quality and accuracy of maintenance audits. You should devise robust plans to implement audit recommendations for better productivity and business success and the audit team should document the entire process for future reference.

Bryan Christiansen is the founder/CEO of Limble CMMS, 3290 W. Mayflower Ave., Lehi, Utah 84043, 801-851-1218, www.limblecmms.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada