North American Manufacturing Lead

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Understanding manufacturing sustainability

4 pitfalls to avoid when launching sustainability initiatives

- By Jennifer Johnson

- December 13, 2022

Sustainability is quickly becoming part of the everyday vernacular in the manufacturing sector, and consumers and employees alike want to align themselves with environmentally and socially responsible companies.

But, whether it’s an intentional improvement to your company footprint or a legislative-driven initiative, programs can get off track quickly if they aren’t grounded in the right principles. Here are four pitfalls to avoid when implementing or revamping a sustainability program:

1. Ignoring United Nations Sustainable Development Goals (UNSDGs)

Companies that tie each of their initiatives to one of the 17 UNSDGs can report results in a format consistent with other companies, ideate as they identify gaps, and amplify progress. Many manufacturers don’t realize that they already have continuous learning, internship programs, and training that tie to SDG No. 4, Quality Education.

A Power App—custom-built apps for unique business challenges—is one way to enable employees to submit ideas and for leadership to consider them and tag them to a UNSDG. Some of those ideas may end up being scalable to the under-served in the larger community.

2. Lacking Targets, Measurability, and Amplification

Understand the measurable targets available for your industry and document their averages for a relative starting point and trending. A lack of measurable targets against industry standards can leave your statistics and results looking a little obscure.

Technology, such as Microsoft Power BI reporting software, enables manufacturers to benchmark and provide more meaningful data to share with customers and employees. And speaking of sharing, promote the program and results to your stakeholders and ecosystem. If you’ve reduced your carbon footprint, changed to a local supplier, or modified packaging, posting the information to LinkedIn and Twitter and using other marketing channels is a very easy way to put your company top of mind with prospects, customers, and potential employees.

3. Thinking Solely Within Your Four Walls

Most manufacturing companies will focus the bulk of their sustainability initiatives within plants and on end products. However, with the recent disruption to how we all work, some measurable sustainability activities that most companies should count towards their results include:

- Permitting some employees to work remotely, which decreases commuter emissions, necessary office footprints, and electricity utilization.

- Finding measurable activities in the supply chain beyond the obvious recycling and green materials, such as sourcing closer to your manufacturing destination, ordering full truckload (FTL) instead of less than truckload (LTL), and reducing the use of overnight/air freight.

- On the manufacturing floor, considering chip recycling, using a higher quality coolant with fewer changeovers, reworking tooling rather than buying new, bringing outside operations in-house, and limiting transfers from site to site.

4. Keeping It a Leadership-only Initiative

While any active program at an organization needs the political (and sometimes financial) willpower of organization leadership to develop and advance, many of the executable ideas are already incubating with your employees.

Shop floor and office support know where a company could implement a sustainability initiative. Are pallets being reused or recycled? Are lights on in an underutilized area? Are doors open year-round allowing energy to escape? Are short-ship and partial orders consistently received on the dock, or are trucks idling in the yard for longer than they should?

Ask your employees, and reward them for their feedback with recognition on your platform and something tangible for the team, like a small bonus or gift card.

Clearly, there are lots of flavours and scale to a sustainability program. And although every company is at a different spot on the maturity spectrum with their efforts, they share a common desire: to make a genuine impact.

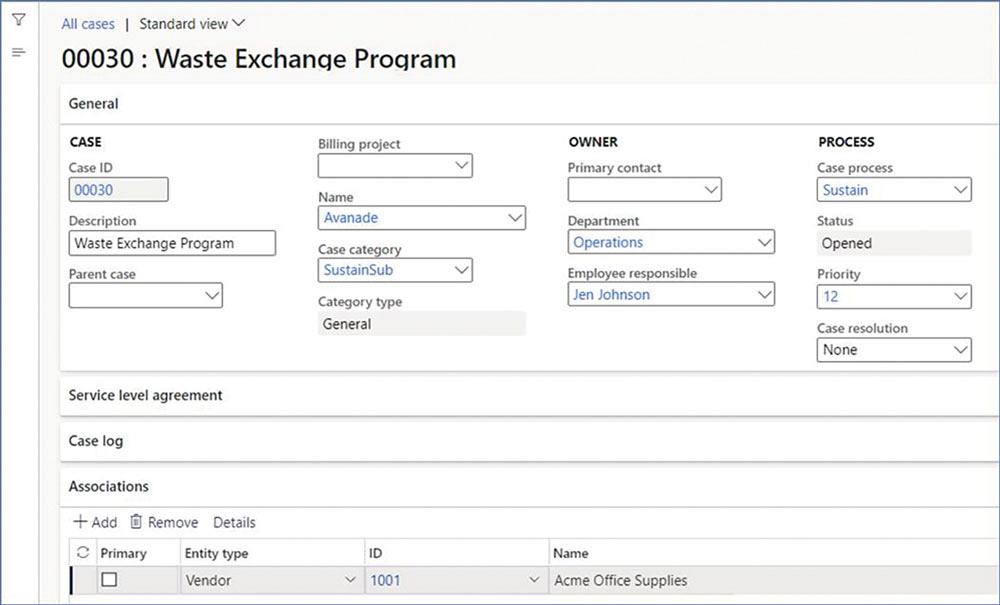

Using Microsoft Power Apps and Power BI and case application within an ERP, such as Microsoft Dynamics365, helps you avoid pitfalls that undermine your efforts and unlock the quality of flow, management, and reporting that demonstrates sincere efforts and generates excitement.

Jennifer Johnson is North American manufacturing lead at Avanade, 1191 Second Ave., Suite 100, Seattle, Wash. 98101, 206-239-5600, www.avanade.com.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada