- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business of tooling: Competitive advantage

There are many ways for today’s machine shops to gain a competitive advantage.

- By Canadian Metalworking

- July 30, 2014

Competitive advantage is what all shops use to gain more business. The advantage could be the price of the product a shop sells to its customer. It could also be the quality of the product or the lead time. However, generally it is all of the above. The question is how do we gain a competitive advantage and how do we maintain it?

There are many ways for today’s machine shops to gain a competitive advantage. It could be with new state of the art multi-axis CNC machines, highly skilled quality machinists, and fast turnaround times to name just a few. The focus of this article however will be related to creating and maintaining a competitive advantage through the use of cutting tools.

Imagine a shop producing a cavity in a steel block from solid. The cavity is 48” square by 6” deep. Some older cutting tool technology would suggest using a round insert “button cutter” to produce this part. A 4” diameter cutter, taking a 0.100” depth of cut (DOC), 500 surface feet per minute (SFM) and a feed rate of 0.014” per tooth. This would take the customer 2 hours and 42 minutes to produce this cavity.

Another company moved to high feed milling. Same speed, same number of teeth but .040 feed per tooth. That’s 153 PM but the travel is further. Since high-feed has a maximum depth of 0.06” per pass. The time required to produce the cavity using this high-feed milling is 1 hour and 15 minutes.

Today’s generation super high feed cutters would be capable of producing this cavity in only 38 minutes.

For this example let’s assume all three companies are quoting on a 200 piece order. With a shop rate of $100 per hour. Company one would quote $53,800, company two would quote $25,000 and company three would quote $12,500.

Who will be awarded the contract?

The first company will require over 13 weeks to complete the job. The second company will be able to complete the job in just over 6 weeks and the last company can complete the job in just 3 weeks.

Company one could reduce its price to $23 per hour to compete, however they would still be at a disadvantage due to the lead time required.

The reality is company one would likely charge less than $100 per hour and company three would likely charge more than $100 per hour. Therefore by embracing new technology machine shops can make more money and put more business through their shop with less equipment.

However this advantage is fleeting. Any of those companies could switch to super high-feed milling and level the playing field. Unfortunately many shops can be stubborn or close-minded. An attitude of “this is the way we have always done it” is a recipe for obsolescence. Technology is changing quickly and those that embrace the change will thrive, while those that resist change will perish.

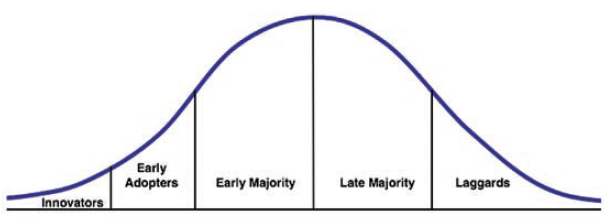

When a new cutting tool technology is introduced shops embrace it in categories as described in the diagram below.

The innovators, early adopters and early majority shops are those with a competitive advantage. These companies tend to win more contracts and make more money.

It’s not just super high-feed milling. Many shops are still grinding hardened parts when they could be using CBN, or replaceable tip end-mills instead of solid carbide end mills just to name a few.

To create and maintain a competitive advantage today’s machine shops need to become innovators and early adopters of technology. This requires changing the culture of your shop to one that is open minded and willing to change and experiment with new technology.

Technology is changing exponentially. Advances in technology enable faster advances in technology.

At one time shops could rely on trade shows to keep up to date on the latest technologies. However, attending a trade show once every two years will not suffice. Technology is moving faster than that.

One way to gain a competitive advantage is to invite your cutting tool sales person into your shop and ask them to make suggestions for improvements. Progressive shops will invite all cutting tool suppliers not simply the one you have always used. These factory trained reps are up to date on the latest in cutting tool technologies and are more than willing to bring in tools to try on your spindle. Best of all is this is a free resource.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI