- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Technology renewal the theme of Italian machine tool show

- January 8, 2019

- News Release

- Management

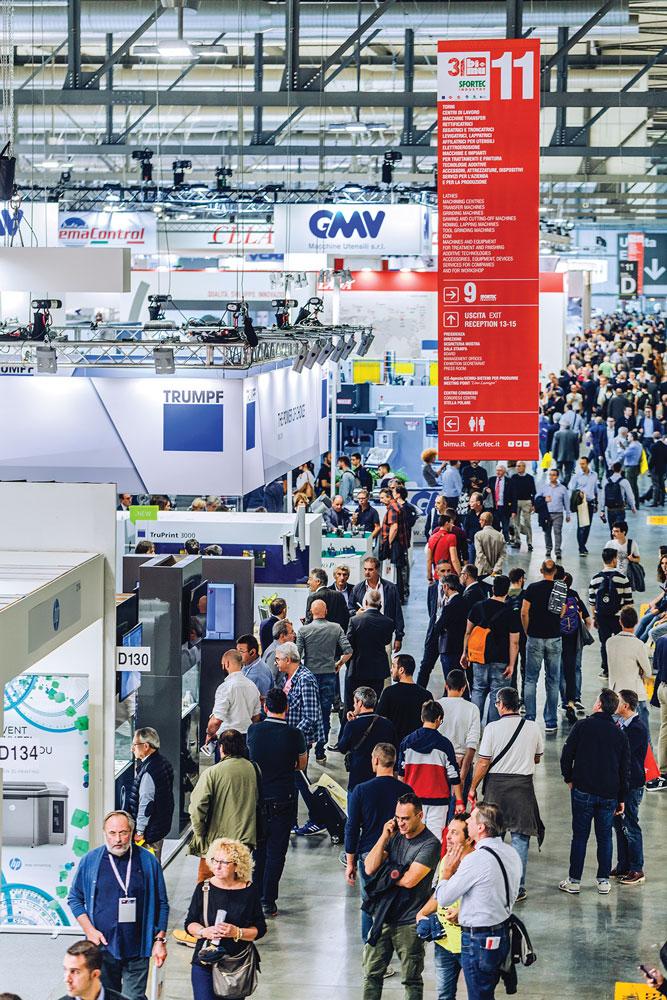

In October Milan, Italy, hosted the 31st edition of the BI-MU machine tool show that featured the latest machine, robotics, automation, and auxiliary technology.

More than 65,000 visitors attended the five-day event, which was promoted by UCIMU-SISTEMI, the Italian machine tool, robotics, automation systems, and ancillary products manufacturers’ association and organized by EFIM (Italian trade fairs), to view the product offerings from 1,056 companies.

The Toronto-based Italian Trade Commission (ITA) invited several manufacturing executives from across the country to visit the show. While the overarching theme from among the group was an ongoing need to automate processes to combat the lack of skilled labour, many machining technologies were examined.

“I personally was very impressed with the BI-MU show. It was well-executed and addressed all of my current needs for making buying decisions. I was most impressed with the emphasis on automation and the Industry 4.0 manufacturing philosophy,” said Anthony Tersigni, vice president – operations, New Era Group, Toronto.

The main objective of the ITA-sponsored program is to give Canadian companies exposure to advanced technological systems available from Italian equipment builders.

While many Italian machinery builders have established North American operations, it can be difficult for metalworking shops to learn about and connect with niche, non-mainstream technology and applications available through smaller, more specialized suppliers.

“We invited over 200 companies from 14 countries to BI-MU 2018; a similar number participated to the delegation to the Lamiera show in 2017,” explained Matteo Picariello, Italian trade commissioner. “Canadian manufacturers are increasingly looking for comprehensive systems to increase the productivity, profitability of their operations, and to add value for their clients. It is not just a matter of buying a piece of equipment anymore. Nowadays choosing the best-fitting technology involves a deeper level of understanding between the end user and the supplier.”

Delegation programs such as this trip represent good learning experiences and provide networking opportunities for Canadian shop owners.

“In my mind I always prefer to see the equipment I’m buying or interested in buying firsthand. I believe that most buyers want to touch and feel as well as see what we are buying. Therefore, to me it is a 100 per cent requirement when buying equipment,” said Tersigni.

Among the delegates from Canada was Robert Cattle, executive director of the Canadian Tooling & Machining Association (CTMA).

According to Cattle, it’s important for Canadian companies to create as many strategic partnerships as possible to succeed in the complex world of manufacturing. Sourcing new equipment from many suppliers is just one of the ways this can be accomplished.

“As technology continues to move forward at a rapid pace and automation, robotics, and artificial intelligence become more integrated into machine tools, owners and plant managers must keep pace with these developments and implement them on their shop floor to enable Canadian companies to be competitive globally,” said Cattle.

It’s a sentiment that is shared by Picariello.

This is because Italy and Canada both have a dynamic advanced manufacturing industry in which growth is driven by small and medium-sized companies.

“Canadian manufacturers and Italian machinery builders face the same challenges: labour shortages, the pressure to reduce costs, and regulatory constraints. SMEs need to innovate to survive. Italian machine builders can supply the process and technology innovations that are essential to Canadian SMEs.”

The next BI-MU fair will be held Oct. 13-17, 2020.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI