- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Renishaw observes dual events with tours, demonstrations, and presentations

- December 14, 2017

- News Release

- Measurement

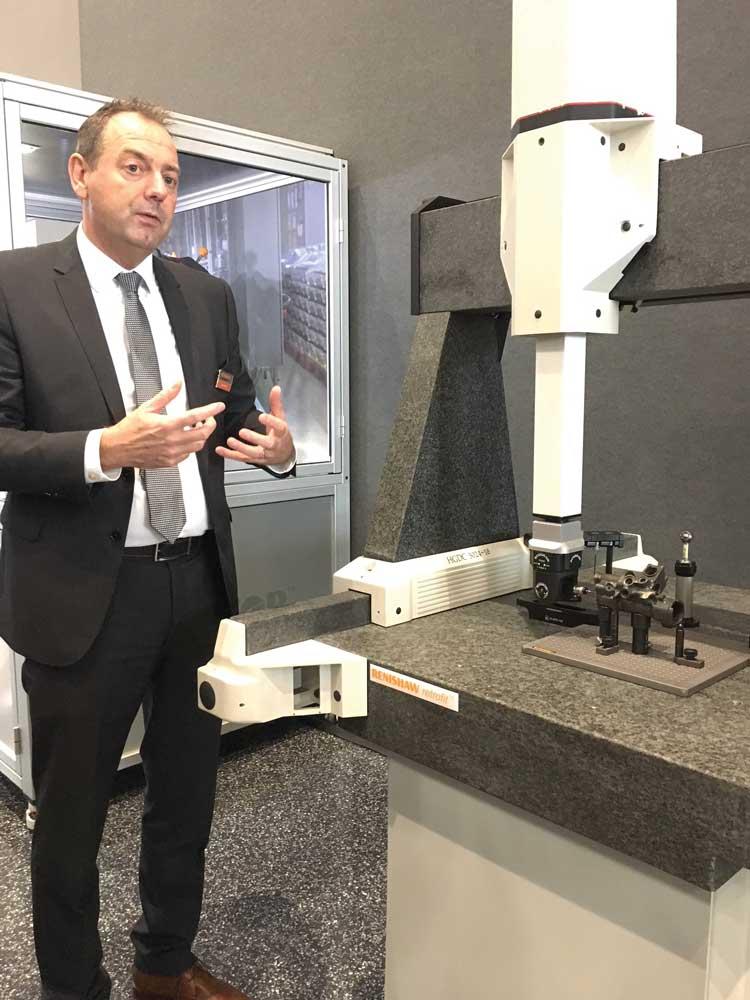

Paul Maxted, director of industrial metrology applications from Renishaw’s Gloucester, U.K., headquarters, explained the importance of accurate fixturing during the measurement process during the West Dundee Innovation Fest.

Renishaw Inc. celebrated its 40th anniversary and the opening of its new Solutions Center in West Dundee, Ill., during a two-day Innovation Fest in October. The 133,000-sq.-ft. building, 40 miles from Chicago, will serve as the company’s North American headquarters. It features dedicated demonstration areas for the company’s products, including the Additive Manufacturing Solutions Center, Industrial Metrology Solutions Center, Gauging Lab, and Calibration Lab, with many hands-on displays. A 47,000-sq.-ft. warehouse, a service and repair centre, office space, educational venues, and meeting space complete the facility.

Educational presentations by guest speakers and Renishaw staff members addressed topics related to high-volume CNC production, the anticipated 2018 upheaval of the auto industry, and additive manufacturing as it relates to the automotive industry and its effects on machine shops.

Demonstrations included:

- RenAM 500M, the first offering in a family of products that build metal components using metal powder bed fusion technology.

- XM-60 multiaxis laser calibrator capable of measuring 6 degrees of freedom in any orientation for linear axes from a single set-up.

- SFP1 probe option for the REVO® 5-axis measurement system that allows surface finish inspection to be fully integrated within coordinate measurement routines and automatic switching between dimensional and surface measurement.

- Intelligent Process Control (IPC), now available with the Equator™ controller, that uses recent historical gauging data to determine process corrections for lathes, machining centres, and highly automated machining cells.

- Equator paired with a TP20 module changing touch-trigger probe that allows the use of multiple stylus configurations and extensions to access features on complex parts.

- SPRINT™ system that incorporates a new generation of on-machine analog scanning technology for prismatic and complex 3-D components with the ability to measure 1,000 true 3-D data points per second.

The West Dundee Solutions Center joins Renishaw Canada in Mississauga, Ont., in serving the North American market.

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI