- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Marposs OptoCloud EDU inspection system provides fast measuring of EV components

- November 24, 2022

- Product Release

- Automation and Software

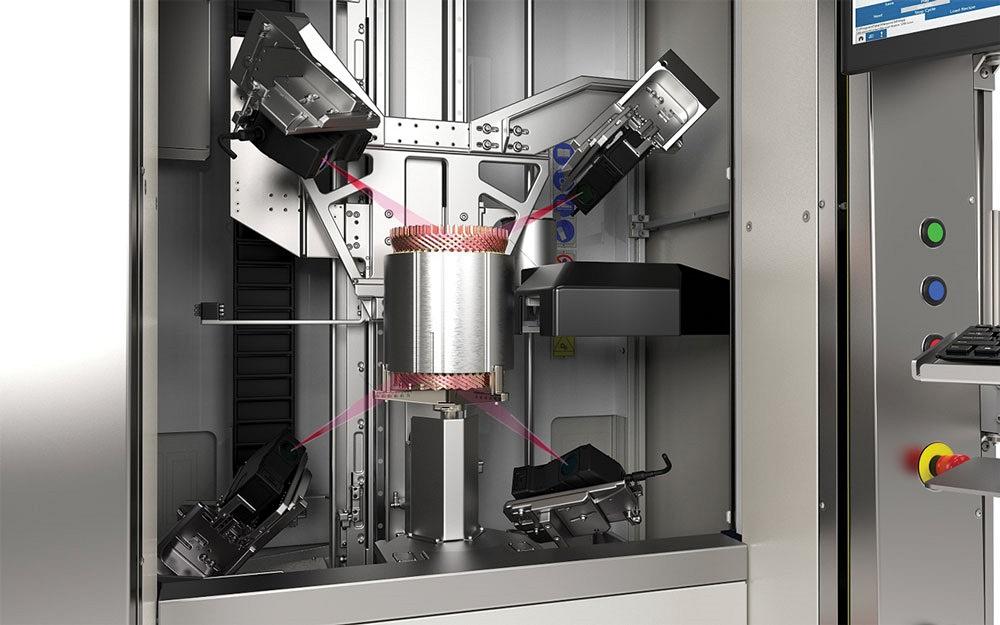

Marposs Corp. has developed the OptoCloud EDU (electric drive unit), its latest generation of 3D precision inspection systems designed for the electric vehicle industry.

Using multiple laser heads in tandem with contact sensors for measurement and vision inspection, the system reconstructs the 3D model of complex and articulated workpieces in less than one minute to help ensure accuracy of the produced component. For example, it can validate 240 electrical contacts of a motor stator in only 30 seconds.

The laser heads are integrated over a moving axis designed to position the lasers for the 3D acquisition. To generate a point cloud of the workpiece, the part is rotated 360 degrees while the different laser heads each acquire spatial data that is then combined into a single 3D reconstruction and graphical representation made possible through the software. The system then executes the requested measurement and vision inspection tasks.

The laser heads also create a point cloud with such a high level of spatial resolution that the details provide a reliable dataset that can also be used for design reviews and final project validation, the company states.

Part handling is simplified because its design features a Z-axis that allows the laser heads to automatically move out of the handling area, leaving space for workpiece handling and removing risk of sensor damage caused by handling errors.

Components up to 300 by 300 mm weighing up to 60 kg can be measured.

Marposs Corp. | www.marposs.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

GF Machining Solutions names managing director and head of market region North and Central Americas

Mitutoyo updates its end-user portal

Enhance surface finish with high-speed machining

CME's Health & Safety Symposium for Manufacturers

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada