- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Software simplifies multitasking

- June 20, 2016

- Product Release

- Automation and Software

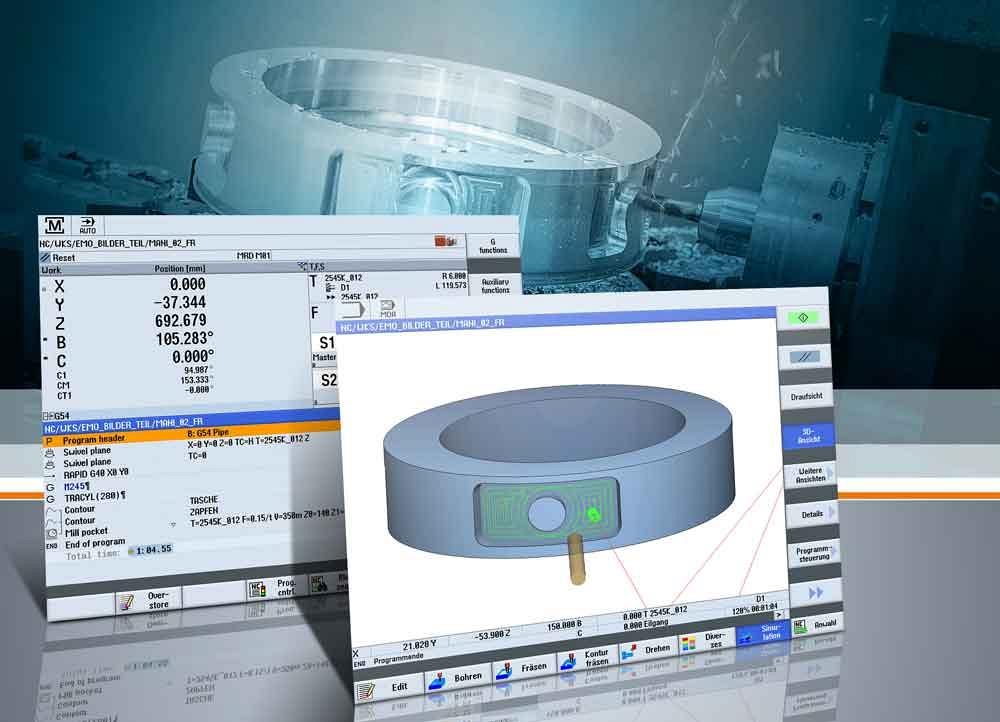

Siemens has released version 4.7 of its Sinumerik Operate graphical user interface, which has improved function for multitasking with machine tools. The software and the Sinumerik 840D sl CNC combine several machining technologies such as turning, milling, and drilling, as well as workpiece and tool measurement, on one machine.

The new version includes extended setup and manual modes (JOG), which now interactively support the user when setting up mill/turn machines. In the new measurement function for turning tool, the setting screen automatically changes depending on the tool type being measured.

In addition, workpiece measurement now enables the user to check and specify the workpiece zero.

The setup of turning tools has been simplified. Now when the user selects a turning tool, the machine automatically switches to turning mode.

Tool management has also been extended in this version of the software. The display now shows every tool for the technologies used on multitasking machines.

Apart from the most frequently used turning, milling, and drilling technologies, along with measurement functions, a number of additional production technologies can be implemented on a customer-specific basis. These include grinding, gear hobbing, and hob grinding; laser, electron-beam, and plasma welding; eroding, laser, and waterjet cutting; and nibbling, honing, and shaping.

Siemens Industry * 800-879-8079 * www.siemens.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada

DiPaolo Machine Tools Open House 2024

- June 4 - 5, 2024

- Mississauga, ON Canada