- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Solid carbide drill features a new innovative thinner web

- October 24, 2023

- Product Release

- Cutting Tools

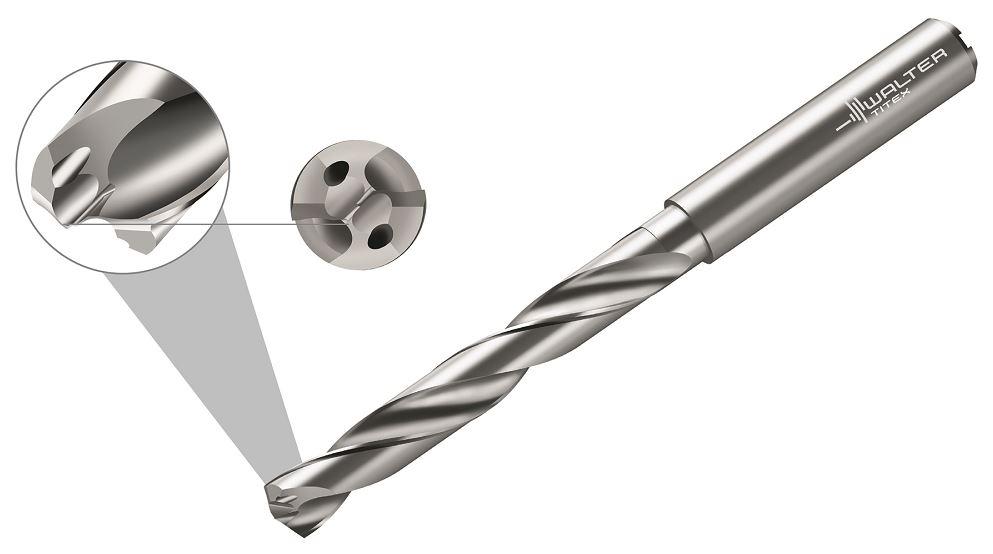

Walter has introduced the new DC166 Supreme solid carbide drill. It has been specially developed for machining aluminum and other ISO N workpiece group materials, such as copper, brass and bronze.

The drill with internal coolant features optimized point geometry creating a “coolant pocket” that provides more space for coolant flow resulting in better chip evacuation. In addition, the patent-pending web design results in sharper cutting action that prevents built-up edge and enhances chip removal.

All the key surface on the drill—flutes, land, and flank faces are polished. Polishing reduces friction and prevents adhesion (built up edge) when drilling highly gummy material.

The carbide drill can be used with emulsion, oil and minimum quantity lubrication (MQL).

The standard DC166 Supreme is for drilling holes up to 5xD in accordance with the DIN 6537 long standard. The drill is available from 0.118 to 0.472 in. (3 to 12 mm) in diameter.

Walter also enables the tool to be ordered as a special for drilling up to 30xD in a diameter range from 0.118 to 0.787 in. (3 to 20 mm) via the Walter Xpress Service.

Walter Tools | www.walter-tools.com/us

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

Sustainability Analyzer Tool helps users measure and reduce carbon footprint

CTMA launches another round of Career-Ready program

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI