- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

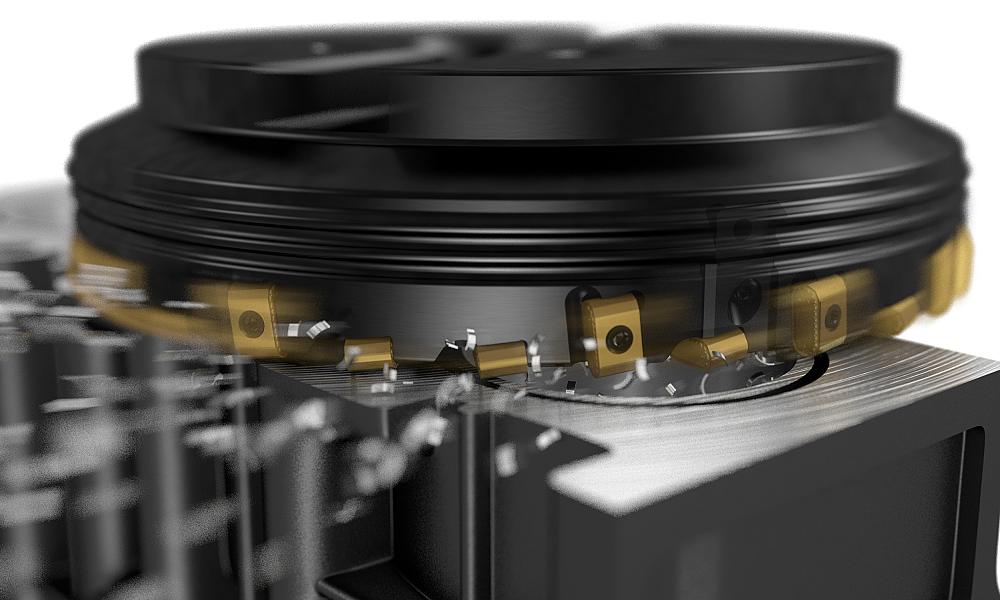

Sandvik Coromant face milling tool for automotive

CoroMill 425 offers easy adjustment and higher performance for the finishing of cast materials

- February 5, 2016

- Product Release

- Cutting Tools

With CoroMill 425, Sandvik Coromant offers an eight-edge user-friendly finishing tool designed for face milling that improves metal removal rate and tool life in the ISO K application area.

Sandvik Coromant has introduced CoroMill 425, a finishing tool for the face milling of cast materials. With its eight edges it is ideal for face milling components such as engine and cylinder blocks, axle housings, brake carriers and crankcases made of GCI, NCI and CGI materials. Due to its patented setting system the tool features precise insert positioning that makes set-up very simple.

On the CoroMill 425, the same inserts can be used as working or as wiper inserts. The wiper inserts are mounted in cassettes on the face of the tool. The insert version with a 25° entry angle and optimized chamfer is designed to reduce breakouts and burr formation on the workpiece. A choice of wear-resistant GC1010 PVD insert grade for dry milling and K20W grade for wet milling enables especially long tool life in CGI materials.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Automating additive manufacturing

CTMA launches another round of Career-Ready program

Collet chuck provides accuracy in small diameter cutting

Sandvik Coromant hosts workforce development event empowering young women in manufacturing

GF Machining Solutions names managing director and head of market region North and Central Americas

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI