Director of Product Development for Gas Equipment

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

It doesn’t have to be acetylene

Alternative gases can be a good choice for oxyfuel cutting

- By John Henderson

- April 11, 2017

- Article

- Fabricating

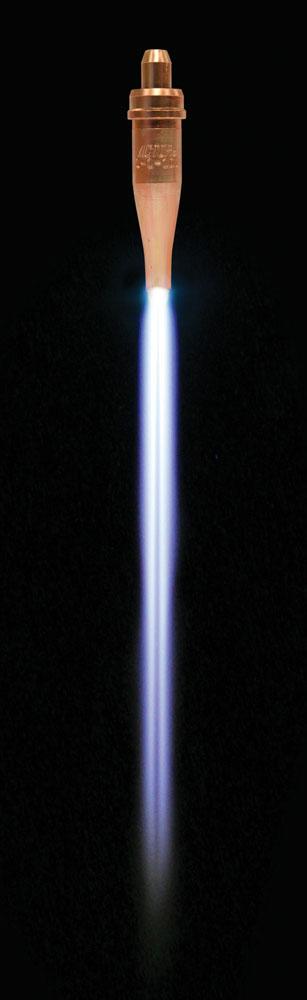

The slower burning rate of alternative fuels requires using a recessed tip to create more space for proper flame attachment.

Acetylene is the most common fuel used to create the preheat gas for oxyfuel cutting. But there are alternatives, depending on the application, that can be less expensive, provide more BTUs per dollar, and reduce cylinder costs.

John Henderson, director of product development for gas equipment at ESAB, answered some questions and dispelled some myths associated with switching to an alternative gas for an oxyfuel cutting process.

CFW: What are the alternative fuel options?

Henderson: Globally, acetylene is the most prevalent gas used for oxyfuel cutting—it’s probably used in 80 per cent of the applications. But there are basically three other predominant gases that can be used. They are natural gas and two liquefied petroleum (LP) fuels—propane and propylene. Proprietary fuels expand the options, but they are generally a blend that starts with propane or propylene and contain some additives that create a slightly different burning configuration.

All the gases generally can be used for all cutting processes. Oxyfuel welding is an exception. That requires acetylene.

CFW: What is misunderstood about the alternative fuels?

Henderson: A misconception about using alternate fuels is that because they don’t burn quite as hot, they don’t cut as well or as fast. All of the commercially available fuel gases have a high enough flame temperature to achieve the desired results when used with the correct equipment and proper techniques.

Once you actually start cutting, the oxygen does the work, so speed of cut isn’t a consideration when choosing the preheat gas. The preheat part of the process just gets the material to the kindling temperature to start the actual cutting.Theoretically, when you use alternative fuels, you can preheat large material faster than when you use acetylene.

CFW: What are some main differences between cutting with acetylene and alternative gases?

Henderson: Acetylene has a very concentrated heat profile, a precise heat-affected zone that lets you pinpoint the location of the flame. It works well for cutting thin materials.

A Grade T hose should be used with alternative fuels to prevent the liquid phase of the fuel from permeating through the gas hose and into the oxygen hose.

Conversely, the alternate LP gases are the opposite and can work well for cutting thick materials. They have a feathering type of flame so they can heat a larger area faster.

Acetylene has some flow delivery restrictions, and the required flow rates could make it necessary to manifold several tanks together. The only limitation with an alternate fuel is how quickly it can vaporize the liquid to a gas. An LP gas cylinder can provide significantly more cutting than a cylinder of acetylene.

If you are cutting a large fixture and the process will draw a lot of gas, it can be wise to consider an alternative fuel that will give you a large, robust flame using less fuel.Natural gas is generally used in a piped-in situation in a large facility or when large or automated cutting tables are used.

CFW: Do alternative fuels require different equipment?

Henderson: You can’t switch from one gas to another with the same equipment. A conscious choice needs to be made so the equipment can be properly paired with the gas. The regulator, hoses, and torch tip need to be selected according to the chosen fuel. There is no need to change the torch as long as it has a universal or spiral-type gas mixer and a gas delivery above 2 PSI.

A regulator used with propane or propylene gases needs to be approved for use with liquefied petroleum gases and marked “LP Gas.” Although alternative gases don’t have the delivery pressure, withdraw rate, or storage issues associated with acetylene, we recommend that a manufacturer consult with its welding supply distributor when switching to a new fuel gas.

A Grade T hose, recommended for use with the alternative fuels by the Compressed Gas Association and the Rubber Manufacturers Association, has a neoprene liner that won’t allow the liquid of an alternative fuel to permeate it. Grades R and RM hoses, sometimes used with acetylene, can potentially allow LP gas to permeate through their walls and into the oxygen hose.

Alternative fuels burn back toward the torch tip at slower rates than acetylene. Achieving the proper flame attachment, the standoff between the end of the tip and the ignition point of the flame, requires using torch tips engineered to accommodate the specific burning rates of the fuel gases. Consumables for the slower-burning gases have recessed tips that create more space for proper flame attachment.

CFW: Are techniques for lighting and extinguishing the torch the same for acetylene and alternative fuels?

Henderson: Alternative gases have a tendency to float up or down. The natural gas is lighter than air, while propylene and propane are heavier. Acetylene has about the same density as air. The weight differences mean that operators need to learn different methods to safely light and extinguish the torch. When the alternative fuels are used, the flame needs to be walked up or forced to prevent starving and extinguishing it.

After you light the torch and add the initial preheat oxygen, alternately add more fuel and oxygen by opening the respective valves one-quarter to one-half turn at a time until the fuel gas valve is completely open. Then add oxygen until the flame creates a loud whistling sound and the primary flame reaches its shortest point. Depress the cutting oxygen lever and readjust the preheat oxygen if necessary. If you are using propylene, adding an additional small amount of preheat oxygen will produce a more concentrated flame.

When you extinguish the flame, you essentially reverse your lighting process. Walk the flame back down by alternately reducing fuel and oxygen until you have completely shut down the oxygen, leaving only the fuel open and lit with a small, easily managed flame. Then, finally, fully close the fuel valve, extinguishing the flame.

CFW: Are the alternatives application-specific?

Henderson: Generally, all of the alternatives can be used for all cutting applications. An exception is oxyfuel welding in which you need to use acetylene because a proper mixture of oxygen and acetylene with a neutral flame produces CO2, which in turn shields the molten puddle from atmospheric contamination. The alternate fuels do not create any shielding gas.

CFW: Do you have any final comments for manufacturers considering using an alternative fuel?

Henderson: Every gas has a positive and negative, so it comes down to looking at the benefits and weighing them against the application requirements.

ESAB, 800-426-1888, www.esab.com

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Gema welcomes controller

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI