Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Brenco celebrates 40 years

Relationships are key to success, says Delta, B.C. institution’s leadership

- By Rob Colman

- November 10, 2023

- Article

- Fabricating

Brenco Founder and former President Steve Heim with current President Vanessa Heim during the company’s 40th anniversary celebrations. Photos: Ryan McLeod

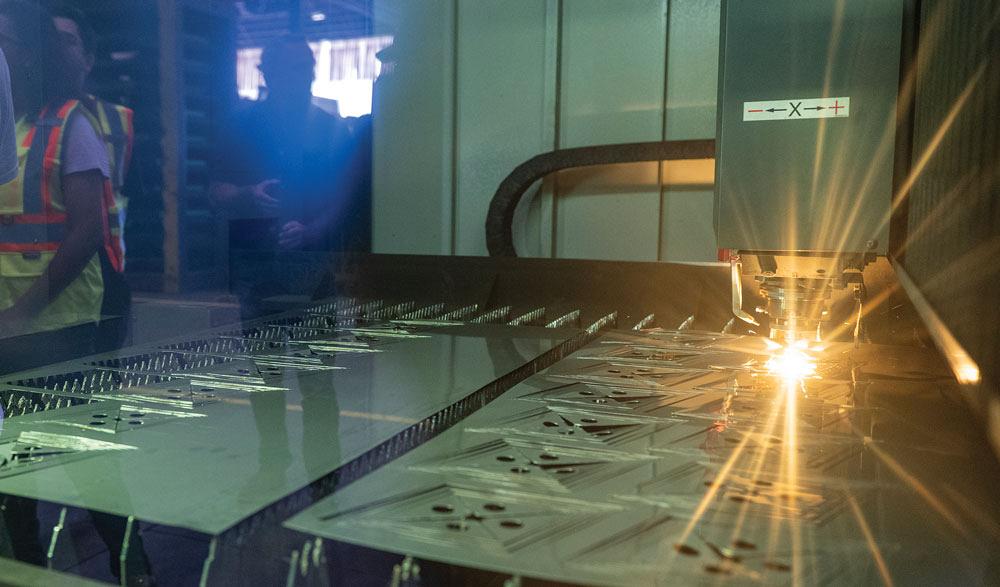

On Sept. 7, Delta, B.C.-based Brenco celebrated 40 years in business with an open house. The event included tours of the company’s facilities and demonstrations of its new 10-kW Mitsubishi fibre laser.

Forty years in the fabrication industry is no small feat. Canadian Fabricating & Welding spoke to current company President Vanessa Heim and former President and Founder Steve Heim about what has driven that success. Though we spoke to them separately, the similarity of their answers is an indication that theirs is a deep-rooted company philosophy focused on personal connection with employees, suppliers, and customers.

Culture Is Key

Brenco was founded by Steve Heim with the support of his parents.

“I was only 25,” he recalled. “I had no knowledge of how to start a company. I just wanted to create an environment that was enjoyable to work in. I had worked in my dad’s company, and it was great when it was only five of us working there, but as the company grew, that atmosphere and culture changed, and I really wanted to create a business that could maintain that enjoyable culture. But I never anticipated celebrating 40 years in business.”

Vanessa Heim took over the business two years ago and has no intention of changing the fundamental tenets of Steve’s business approach.

“My dad has instilled in me the fact that we wear many hats,” she said. “There’s nothing that is beneath me when it comes to the business. I’ll pick up a broom or clean out a storage closet—whatever is necessary to make sure that my team has what they require to get the job done. Because really it comes down to them, it comes down to the people.”

Handling the Challenges

Some of Brenco’s customers have been with the company since the first month it was open. Both Steve and Vanessa said the key to their success is not just producing projects on time and on spec, but also knowing how to manage relationships when things go wrong.

“It’s inevitable that something will go wrong,” said Vanessa. “You’re dealing with imperfect people and imperfect drawings. Not only is the customer relationship important, but it also makes a big difference how you fix it when things go wrong, how quickly you do so, and how you stay on top of it by communicating effectively.”

Treating suppliers with the same respect is crucial also.

“We’ve always paid our bills on time,” said Steve. “We knew that by doing so, we would always have the support of our suppliers, which is critical to any business.”

Personal Connection

Communication within the company is just as important, especially as industry changes, with so much being done online in a very impersonal manner.

“We used to know how busy we were by how much the phones were ringing,” said Vanessa. “Now, that’s no longer the case. People communicate by text and email, and in the process, they lose that personal connection.

“We try to encourage our project managers to pick up the phone and speak to customers as best they can,” she continued. “We have an open office for the majority of our project managers, which also aims at better communication. They can overhear what is going on around them, and they can offer advice or support, or discuss scheduling to make sure that projects move as smoothly as possible through production.”

Such relationship building is crucial in such a small market.

“We have the border to the U.S., mountains, and ocean around us,” said Vanessa. “We don’t often ship outside of our region and are very well known in our market area. It means we have to be very diverse and support our customers well.”

Brenco works on everything from water parks to artists’ installations, so being agile and able to adjust to the unique needs of each customer also is key.

“When you’re dealing with engineers, they are interested in tolerances and dimensions,” said Steve. “An artist, meanwhile, is interested in texture and feel and all the sensory aspects involved in making a piece of art, so we have to adapt to that. It’s a different language.”

Technology Uptake

Keeping up with technology has been important for the company as well.

“We put our first laser in in 1997,” said Steve. “That was a huge step — a 1.6-kW laser. Suddenly, we were able to create parts that we couldn’t have before. Not everything required the straight lines of a shear.”

Now, with its new 10-kW laser, the company is again equipped with the latest and greatest.

Tours of the Brenco shop highlighted the company’s new 10-kW Mitsubishi fibre laser, among other things.

“That machine is incredibly fast,” said Vanessa. “It’s our first laser that requires two people to run because it produces so quickly. We have 10 press brakes and still struggle to keep up with the one 10 kW and our two older CO2s.”

Of course, this is all in aid of keeping a strong workforce busy.

“It’s really important that we create a secure place where employees can be successful and really do what they value, which is raise a family or have an impact in their own community,” said Vanessa.

It’s important to the Heim family to also give back to the community. As part of the open house, Brenco raised money for Honour House, a charity that supports the Canadian Armed Forces, emergency services personnel, veterans, and their families in B.C.

For Vanessa, the open house represented an opportunity to reconnect with the community.

“This is one of the first big industry events that we’ve had in the lower mainland since the pandemic started,” she said. “The brewer from a local brewery that supplied the beer for the event is a former employee. The local winery supplying the event is a customer— we made signage for them. It’s nice to be able to celebrate with former employees—those who have retired and those who have moved on to other work. It’s great to have the community with us here at Brenco.”

The Heims extend their community involvement to the wider metal fabrication industry as well. Steve Heim is a former chairman of the FMA board of directors and Vanessa Heim is a current member of the FMA board of directors.

“My experience with the FMA has been invaluable,” said Steve. “Whether it was board service or committee service, just being able to reach out and develop relationships with like-minded people across the continent was a huge asset.”

Editor Robert Colman can be reached at rcolman@fmamfg.org.

Brenco Industries, www.brenco.com

About the Author

Rob Colman

1154 Warden Avenue

Toronto, M1R 0A1 Canada

905-235-0471

Robert Colman has worked as a writer and editor for more than 25 years, covering the needs of a variety of trades. He has been dedicated to the metalworking industry for the past 13 years, serving as editor for Metalworking Production & Purchasing (MP&P) and, since January 2016, the editor of Canadian Fabricating & Welding. He graduated with a B.A. degree from McGill University and a Master’s degree from UBC.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Gema welcomes controller

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI