- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business Profile: Quality Machining & Metalworks

Manufacturer of gauges and valves is expanding its fabricating operation.

- By Canadian Metalworking

- January 21, 2015

- Article

- Fabricating

After almost 30 years in business, Quality Machining & Metalworks Inc. of Mississauga, Ontario has established an international reputation as the only Canadian manufacturer of high-pressure flat glass liquid level gauges and valves supplying heavy industrial sites around the world. Company founder, Sam Chana, developed the specialized products from his small machining and fabricating shop outside of Toronto, and with a steady line of products feeding the machining side of his business, a recent move nearby to a larger facility is allowing Chana to ramp up the fabricating side of his operation.

Originally from Ludhiana, a major city and industrial hub of the Punjab region in Northwestern India, Chana comes from a metalworking family. “It was in my blood,” he says. “It was what I wanted to do.” Growing up he studied mechanical engineering while also helping build the family business.

When he moved to Canada he landed at a company that was producing high-pressure valves and gauges for the Canadian distributor of an American firm. In 1985 Chana went out on, setting up shop offering both machining and fabricating services. He called his start-up Quality Machining and Fabrication, two years later, when he went to incorporate the business, that company name was taken so he renamed his business Quality Machining & Metalworks.

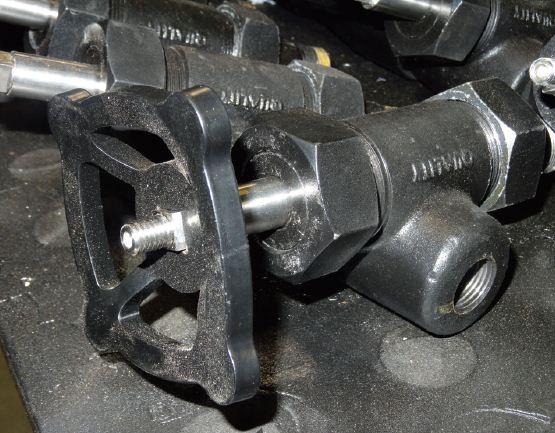

The American gauge and valve firm had pulled out of the Canadian market, so based on the knowledge he had gleaned from working on the products, Chana set out to design and machine his own models of the industrial-strength parts. The high-pressure liquid level gauges (also called sight glass because the levels can be viewed through a glass front) and valve systems are mechanical instruments used to measure reservoir tank levels and boiler levels for the oil and gas and related industries.

In the early days Chana found some custom machining and fabricating business to fill the gaps at his shop and worked on evenings and weekends designing and sourcing materials for his gauges and valves.

“You can’t buy the materials locally to manufacture these products. You have to buy mill-run material because it’s very specialized,” says Chana.

The metal needs to be highly stable, as the products can be used in some very extreme locations. Special grade low-temperature metals, able to withstand climates like Northern Alberta or the deserts of Dubai, specialized bolts and nuts and imported high-impact glass are used on the finished products.

It took Chana about five years to ramp up the production and another five to really break into the industrial gauge and valve market. Now his Quality-branded products, including the only made-in-Canada industrial-strength flat glass liquid level gauges and valves, are sold through a network of international distributors with customers across North America, South America, Europe, Asia and the Middle East.

Chana is able to source his forgings in India at a cost that keeps him competitive in the international market. His ability to perform all of the machining and assembly in-house also gives the company ultimate quality control. “We do assembly and testing of the products. With this product we have to test 100 per cent before we ship it,” says Chana. The company is ISO certified and has special Canada-wide certification for producing these high-pressure devices.

The machining side of Quality’s shop floor is dedicated to the gauge and valve business and operates six aging CNC machines and four manual machines. The day of our visit, Chana shows us three machines being used for three different operations on the valves. He admits that he’s heavily considering a new CNC machine tool, a four- or five-axis, that may be able to perform all the tasks on one machine.

And he’s prepared to invest in this side of his business because it continues to grow. Eric Wolf, vice president sales and marketing at Quality, has been selling these industrial gauges and valves for 40 years, and he’s known Chana for close to 25 years.

According to Wolf, the gauge and valve business is booming. “Twenty years ago they said it was going to be a diminishing market. But with all of the fracking and (other energy production) going on in the U.S., every injection system has a sight glass on it so they can measure the liquid loads on the steam that they’re inserting into the shale,” he explains. “And every refinery around the world, every gas plant, every transmission station has a sight glass. It’s how they calibrate their electronics. And if the electronics fail, these products will still work.”

The competition in this market includes some very large organizations, but because Quality is a relatively small operation it’s able to be nimble and accommodate special requests.

“It’s an extremely competitive market—pennies per pound,” says Wolf. “We win business on delivery. Our reputation is for being better and faster; that’s our niche in the market.

“I don’t want to be cheaper, there’s no skill in that. But there is skill in making products better and being more efficient.”

Although Quality’s focus has been on its valve and gauge business, it accounts for about 70 per cent of the company’s business, it hasn’t abandoned its fabricating side, in fact that’s an area where Chana sees a great opportunity for more growth.

Most all of the fabricating work is custom, with an emphasis on retail fixtures and displays, bus parts (including work for the Toronto Transit Commission (TTC) and GO Transit) and work for the oil and gas sector.

In order to accommodate growth in both its valve and gauge business and expand its fabricating operation, in January 2014 Quality moved into a larger location. The new 37,500 sq. ft. building more than doubles the size of the 15,000 sq. ft. shop the company had occupied for 12 years.

The move also coincided with the installation of a new TRUMPF TruLaser 3030. The company had previously been operating another laser they’ve had for around 10 years. “We were busy on that laser and needed to buy another,” says Chana. The company was also running into limitations with the existing laser, including its ability to only cut up to 5/8-inch material and up to 4- x 8-foot sizes.

To step up its capabilities Quality elected to go with the TruLaser 3030 and 6kW TruFlow 6000 suitable for cutting mild steel and stainless steel up to one-inch and aluminum up to ½-inch. They also selected the RotoLas option for processing tubes and profiles. The bed size is also 30 x 15 ft. (9300mm x 4600mm). “It’s really an amazing machine,” says Chana.

“TRUMPF has been a very nice company to deal with,” says Ronnie Chana, Sam’s wife and the office administrator. It took about a month and a half for the entire installation process and getting up to full operation in the new facility and with the new laser because the company’s move occurred during the ice storm in early 2014. “It was supposed to take us two weeks, but it turned into month and a half,” recalls Ronnie.

Chana’s son Bobby, who recently graduated from engineering at Ryerson University in Toronto, is the one setting up and running the laser operations. He does all of the drawings and autocad programming. In all the company employs about 15 people.

[gallery type="slideshow" link="none" ids="108353,108352"]

Prior to installation of the new laser, Bobby attended TRUMPF’s training facility in Farmington, Connecticut as well as traveling to TRUMPF client sites in Europe to see the machinery in a production setting.

Along with the new laser the company installed a five-ton 120-foot crane to accommodate the heavier gage capacity the new laser can handle, and it also allows the company to take on larger project work. The install also included having gas lines installed to feed the C02 lasers.

The fabricating side of the business also includes a brake press and welding areas and plenty of room for moving product.

“When you enhance your versatility you increase your potential market. All you have to do is capitalize on it,” says Wolf, who points to a number of fabricating projects completed since the beginning of 2014 and the installation of the new laser, including metal cut outs of popular Disney characters used for in-store displays at the locations in the U.S. One popular example is Pumbaa from the Lion King, cut out about five-feet long and etched on the laser.

He also shows a six-foot-plus metal tube with cut-out keyhole shaped slots to be used for toy racks in retail locations.

Other retail fixture projects include jewelry cabinets and mirror stands. He also describes an elaborate customized shoe stand developed for retail window displays for an international running shoe company.

They also have a large 40-foot assembly project on their floor being prepared for an oil and gas company that will be shipped to Fort McMurray, Alberta. It’s a heavy-duty project they would not have been able to complete before installing the new laser.

They’re happy to take on specialized short-run projects that require ingenuity and need quick turnaround. “We’re not a large company, but we insist on maintaining our versatility,” says Wolf.

For their high-pressure valve products the company had been sourcing cast handles, or handwheels. “Then we found another solution,” says Sam, with a laugh. They are now cutting their own handwheels on the new TRUMPF laser, adding another step in the vertical integration of their gauge and valve business, further increasing the quality control of their own Quality-branded products.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Gema welcomes controller

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI