Associate Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

The 3 Ps of MacDon’s success

Ag equipment manufacturer focused on people, partnerships, and process improvements

- By Lindsay Luminoso

- June 28, 2023

- Article

- Fabricating

MacDon Industries in Winnipeg is a true Manitoba success story, and it has grown into a worldwide leader in the manufacture of harvesting equipment. The company has a 75-year history in the province, where its products are designed, manufactured, and shipped around the globe.

The company’s operations division employs well over 1,400 people and is led by Brent Timmerman, vice-president of operations, who joined MacDon in May 2022 during what he calls a unique point in the company’s history.

“Our organization, like many others, is coming out of one of the most significant global disruptions to business in decades, and during that time we launched a major change to one of our signature products, the FlexDraper 2 (FD2)—a combine header,” said Timmerman. “It was a risk, and it came with a lot of challenges. We struggled trying to get new components in what has been dubbed a Supply Chain Armageddon. But we have been fortunate that demand is very strong for this product. Farmers like it, and it has a lot of features that they have been asking for. There is so much pent-up demand for this product, and much like many other manufacturers, we’re trying to catch up to meet demand across our dealer network.”

Coming out of a global pandemic and launching a new product has led Timmerman to reflect on some of the big roadblocks to success and the improvements he helped implement to how the company produces and delivers its products.

Rarely, if ever, can the company stop production for a significant amount of time to make major process improvements or systems upgrades, as huge consequences may result. Incoming material might quickly pile up, filling up space. Workers may need to be redeployed or sales could drop. Customers will then be impacted. In MacDon’s situation, demand was really high for its products, but if it couldn’t meet demand, customers might start to look elsewhere.

As Timmerman said, “This isn't a story of perfection or incredible preparation. It's a truthful account of surprises, trial and error, and realizing that getting back to basics can sometimes make all the difference.”

Bringing the FD2 to Market

The design engineering team had spent years improving the company’s flagship FD1, with significant benefits that users wanted to see to improve their harvesting performance. By chance, the company had committed to a rollout of the FD2 that fell right during the pandemic.

“The FD2 was a massive generational shift in manufacturing requirements compared to its predecessor,” said Timmerman. “It required 60 per cent more purchased or outsourced parts, which meant about 400 more per header, 84 more manufactured parts, and 300 additional pieces of vendor-managed inventory hardware. This meant a significant increase in required support from our supplier partners, and many struggled at first to hit the necessary production throughput rates.”

Key component shortages were followed by staff shortages. This led to slowed production output, creating a gap between the rate of inbound materials (which quickly piled up) and the rate of consumption. Material handling discipline declined, and the company began to lose track of pallets that were needed for production. With rampant parts shortages on the assembly line, many production staff found their time consumed with chasing missing parts.

“But even after some of the purchased parts shortages and staffing shortages began to abate, a sense of hopelessness began to set in,” said Timmerman. “I saw a strange dichotomy last year at MacDon, as we had way too much material and yet not enough, all at the same time. Our incoming material greatly outpaced our production rate until we took the necessary steps to reschedule our production and reissue all of our open purchase orders to push the shipping dates out. At the same time, we were experiencing some shortages of key parts from our suppliers, which continued to cause assembly and sometimes manufacturing problems.”

One of the challenges for the rollout of the FD2 is that it fell right during the pandemic when the supply chain was struggling to keep up. The company focused on hiring and upskilling its workers, adjusting work flow to manufacturing, and fulfilling new product orders. it struggled to get new components from its suppliers which required it to adjust. However, demand for this produce remains very strong.

On the people side of things, workers started to retire or turn to different career paths. As the economy began to reopen, the labour market heated up, creating a very competitive environment that favoured job hopping and increased workforce shortages. This served as a rude awakening for the company, which had historically enjoyed a low attrition rate.

As several seasoned veterans departed the company, Timmerman and his team noticed that several internal processes were dependent on unwritten tribal knowledge, which the new generation of employees obviously didn’t have.

“It also became obvious that we had drifted away from some of the basic good practices like preventive maintenance, operator-based TPM activities, and regular 5S,” said Timmerman. “We were used to a three-week shutdown in the summer and many of our maintenance activities were saved and scheduled for that time. But the problem was we had no ability to even schedule the shutdown, meaning that all those maintenance practices were never done. We were paying a price for pushing off critical maintenance and component replacements. Drifting away from the discipline and best practices had caught up with us because our operations team had also stopped reporting several KPIs. No one had any idea what the score was or if our efforts to improve were having any effect.”

The operations team began implementing initiatives to attempt to stem the crisis. Timmerman grouped these initiatives into three categories: people, partnerships, and process.

People

Timmerman believes that a leader's job is to be the coach for their teams. And in adopting this mindset, it changes the way leaders share information, train and collaborate with employees, design processes, and delegate authority.

“It’s all about shaping a positive workplace environment,” he said. “We believe that our people to come to work everyday wanting to do a good job. Building trust between leaders and staff is critical. We recognize that to get respect, we as leaders need to first demonstrate it to the people that we lead. Both internal and external relationships are incredibly important to us. And while we recognize that we have a very long way to go on our journey, we are committed to building our culture on a foundation of operations excellence.”

One of the ways senior leadership is doing this is by walking the factory floor each day for a full hour, allowing them to visit each production line at least once and areas of high priority multiple times each week.

“It's so important that we hear directly from our production staff and leaders what our current challenges are and to help them solve problems and remove barriers,” said Timmerman. “When we make a commitment to help fix a problem, we need to deliver, or we quickly erode the trust relationships between ourselves and our production leaders.”

As for hiring new employees, MacDon underwent hiring blitzes and made salary adjustments to ensure it didn’t fall out of sync with the labour market. The HR department held career fairs and offered walk-in interview dates. One thing that the company is particularly proud of is hiring over 150 Ukrainian newcomers to Canada, who have proven to be dedicated, hardworking, and welcome additions to the workforce. To support training and translation, the company hired two Ukrainian speakers into the HR department.

And with all the hiring, MacDon realized that it needed to improve training both on the technical and leadership side. So, it hired an experienced leader for the training branch who developed an approach to modernize and provide structure to training. It also finalized development training for all operations leaders to build and enhance the skills required for good leadership.

For Timmerman (right), it’s important for senior leadership to hear directly from production staff about current challenges. He does this by walking the factory floor each day for a full hour, addressing issues and committing to help fix problems.

Partnerships

With so many parts needed to complete a unit, it takes only one missing critical component to make for an incomplete product at shipping. Some of MacDon’s suppliers experienced brief shortages, while others remained challenged for weeks or even months.

The purchasing leadership team implemented a system of escalation reporting to flag critical suppliers by risk.

“Our director of purchasing manages the list of critical suppliers and will bring myself or even our president onto escalation calls with suppliers when production is at risk,” said Timmerman. “Some suppliers worked with us to develop recovery plans, which was fantastic. Some suppliers stopped answering the phone altogether, which was extremely problematic.”

MacDon’s commitment to working with its partners sometimes meant having its staff drive or fly to a supplier’s facility to help them solve any issues. In extreme situations, the company was forced to find a dual source for a part.

“With a lot of hard work over 2022, we greatly reduced the number of critical suppliers from 54 down to 16,” said Timmerman. “Although there are still challenges, we see supply chain stability coming, which will greatly improve our ability to deliver. To attempt to close the material supply imbalance, we needed to address the rate of inbound material supply. This often involved a lot of manual analysis to assess pile up of on-hand quantities and then to work one-on-one with suppliers to reduce the supply rates. This was not easy because we had to accurately predict our changing consumption rates while taking into account current supplier production challenges, as well as long lead times or shipping times. Our approach required a lot of collaboration with our supplier partners. Some of our partners were truly collaborative.”

In challenging times, MacDon found some true partners in its suppliers. A supplier’s ability to be flexible early on in any crisis has helped the company regain stability faster and ramp up its production rate back to normal.

Process

When the material crisis began, many of the company’s production leaders began chasing missing parts. When the parts were found, everyone would celebrate. However, the underlying problem that caused the parts to be lost in the first place had been fixed. This is why MacDon made the shift to address the root causes of some of its problems.

“We learned a few basic lessons during our crisis response,” said Timmerman. “A process that completely depends on the presence of a knowledgeable individual isn't a process at all. The process must be designed to work the same way independently of who is on duty or on vacation. When you start process mapping something with a team of experts, it's surprising how many people have been doing the exact same thing in very different ways for many years. Getting everyone on the same page is the key to stability. Just because you've been doing it the same way for many years doesn't mean that it can't be improved.”

Last year, the company restructured its materials leadership team and transferred long-standing employees with extensive product and process knowledge into senior leadership positions. This has been hugely beneficial. The materials management leadership team has been steadily improving production line site availability of assembly materials, coordinating supplier shipments, integrating lean manufacturing techniques, and changing inventory management systems.

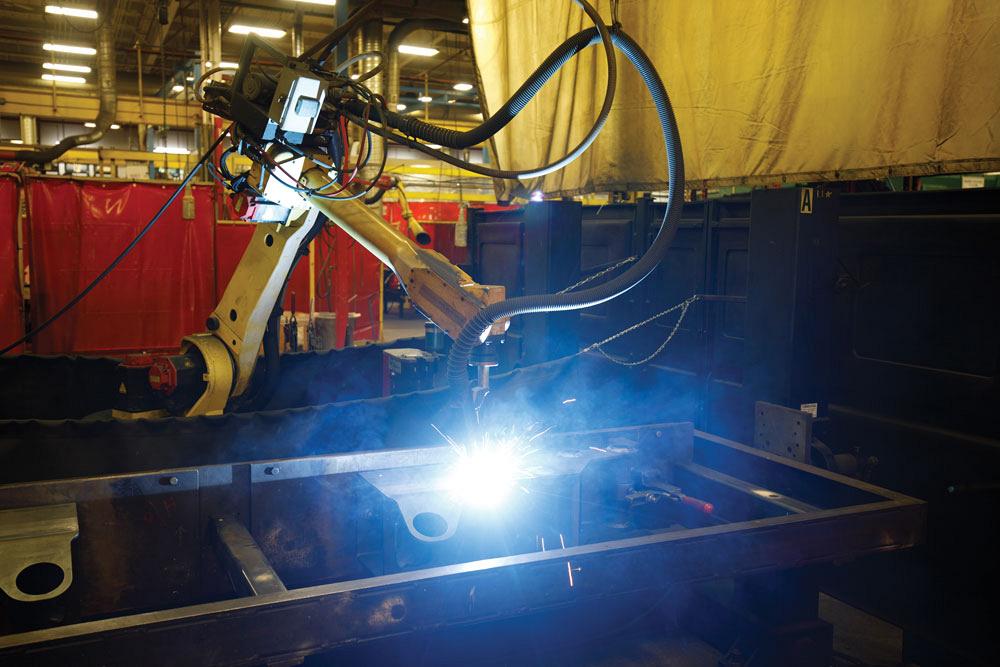

“We redesigned our entire system and material supply chain layout in our factory in order to maximize the reliability of getting the right parts to the right station at the right time,” said Timmerman. “We are investing in new welding capacity, including more robotic welding equipment to support increasing manufacturing capacity for key welded assemblies. We have future plans to invest in additional manufacturing capabilities and upgrade technologies like fibre lasers with automated material storage and automatic part unloading, upgrading small and large press brakes with automated tool changers, and a tube laser.”

To deal with some of the manufacturing bottlenecks that arose during the pandemic, the company invested in new welding capacity, including more robotic welding equipment to support increasing manufacturing capacity for key welded assemblies.

To address the many products that came off the assembly line missing parts and incomplete, MacDon has established substantial completions capacity, with a large, dedicated space for this purpose, along with well-coordinated materials management support, and a significant number of dedicated, highly trained completions production staff. As parts become available, Timmerman and his team are confident that the completions team can help make these products ready for shipping as soon as possible.

Because MacDon had neglected its maintenance activities, the maintenance requests piled up. Its maintenance team made a focused effort to lower the backlog. Since the company hasn’t had a summer shutdown for a couple years, a trend that likely will continue for at least one more year, it needed to learn how to schedule PM activities throughout the year. Sometimes, this has required thinking outside the box, which has been helpful for the company.

The Agricultural Equipment Manufacturing Market

“Like many other manufacturers, we had a rough ride over the past few years,” said Timmerman. “We've been very fortunate that the agricultural equipment market has continued to be very strong since 2020. I know that our dealers had a difficult time managing the expectations for our customers, with changing outlooks and product shortages. Because of all the challenges that we experienced in 2022, we started the 2023 model year much later than we wanted. This means that our 2023 production year was greatly compressed into a shorter time frame than we have ever had to deal with. But despite all this, we still think that we are in a much better place than last year.”

And while Timmerman acknowledges that he joined the company at a unique point in time, his enthusiasm and love for manufacturing is evident in all the initiatives that he has implemented.

“I desperately missed the factory,” he said. “I'm really passionate about process improvement. I like being able to see the changes made. I can head to our floor and see changes taking effect, see how we're doing, and see what the rate of production is. I just like being able to see the physical outcome of what we're doing in a very short time. I’m able to do that within MacDon Operations.”

Timmerman entered the job with a unique perspective. With two farmers in his family, his connection to the agriculture sector is strong.

“One of my brothers-in-law has two MacDon headers,” he said. “I get to hear him talk about our products and see them used in real time, which really makes it impactful in a personal way. I even got to climb in the combine at the family farm this harvest season and see the MacDon headers operating. That was cool. When you think of the different types of industries out there, everyone needs to eat. And the agriculture industry supports food production. It’s one of the most basic needs of mankind. So, it's exciting to be able to work in an industry that helps humanity all over the globe with something very fundamentally important.”

Associate Editor Lindsay Luminoso can be reached at lluminoso@canadianfabweld.com.

MacDon Industries, www.macdon.com

About the Author

Lindsay Luminoso

1154 Warden Avenue

Toronto, M1R 0A1 Canada

Lindsay Luminoso, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. She worked as an associate editor/web editor, at Canadian Metalworking from 2014-2016 and was most recently an associate editor at Design Engineering.

Luminoso has a bachelor of arts from Carleton University, a bachelor of education from Ottawa University, and a graduate certificate in book, magazine, and digital publishing from Centennial College.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Hypertherm Associates partners with Rapyuta Robotics

Protected and productive: welding helmet tech

HGG Profiling Equipment BV names Western Canada area sales manager

Compact weld camera monitors TIG, plasma processes

- Industry Events

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada