- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

SME success stories: Expertise drives expansion

Thomas Wire Die builds for specialty, precision applications.

- By Canadian Metalworking

- August 25, 2014

- Article

- Metal Finishing

A shop can grow its business in many ways. One proven path involves steady expansion based on a foundation of expertise. The consistent growth of Thomas Wire Die Ltd., Burlington, Ontario, is a good example. Founded in 1966 to produce and service small tungsten carbide wire dies, the company built on its experience in making precision parts from hard materials and used it to expand its range of products and customers. And through its nearly 50 years in operation, the shop has continually updated its manufacturing technology to enable it to take full advantage of its special skills.

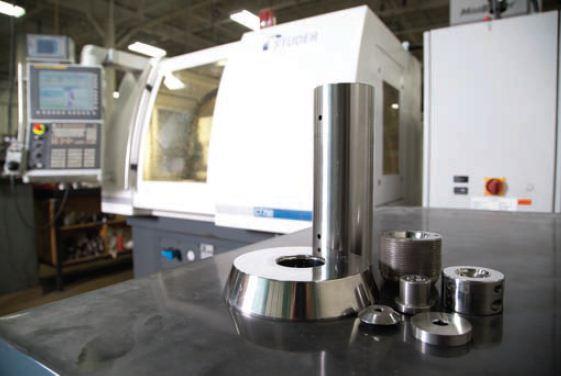

Wire drawing dies are the shop’s original product and continue to be an important part of the business. A typical die is composed of a steel casing that holds a carbide component with a hole through which wire material is drawn. “We buy carbide and steel as raw materials and we machine the steel casing, grind or EDM the carbide, then assemble them into a tool and finish it,” said Adam Thomas, vice president of Thomas Wire Die as well as grandson of the company’s founder.

If the die aperture is round the shop grinds it; if it is square or another shape it is machined via EDM. Part sizes include casings as large as 16” OD that hold a carbide insert with a 12” diameter; among the smallest part features produced are 0.005”-diameter holes in natural diamond wire drawing dies.

[gallery type="slideshow" link="none" ids="105252,105251,105250,105249"]

As time passed, Thomas Wire Die began to produce larger carbide wire and cable dies, then added dies used to cold finish round bar and to draw square, hex and other shapes of bar and tube. Expansion continued with the manufacture of carbide punches and shape dies for forming, stamping and deep drawing, as well as tube drawing plugs and mandrels.

Taking further advantage of its longtime familiarity with the challenges of processing hard carbide parts, Thomas Wire Die moved into engineering and producing carbide wear components. The custom parts combat corrosive and abrasive wear in industrial applications ranging from agriculture to aerospace. “In wear components, we look for opportunities where we can get people to switch from using tool steel to carbide,” Thomas said. “Carbide can provide five times the life of the tool steel. Our customers used to replace a tool steel part every month, now they replace it every six months.”

As the shop expanded its offering of services, it continually augmented its skills with the addition of new manufacturing technology including EDM, turning and milling machines, and advanced CNC grinders that enabled it to serve its traditional markets better and move into new ones.

A notable addition was the company’s 2006 acquisition of Stoney Creek Precision Parts, a machine shop and manufacturer of cold-heading dies used to form bolts and similar products. Thomas Wire Die made the acquisition to help it grow its business in the cold-heading die market and strengthen its machining capabilities.

About three years ago, Thomas Wire Die looked for ways to reinforce its capabilities in the ID grinding that is still the basis of the company’s business. “We grind ID every day, all day, and we asked ourselves what piece of equipment would help us be better in that product,” Thomas said. “We weren’t trying to get into a totally new area; it was work that we already had and we wanted to move it on to a machine that was more efficient and produced higher quality, higher precision and better parts.”

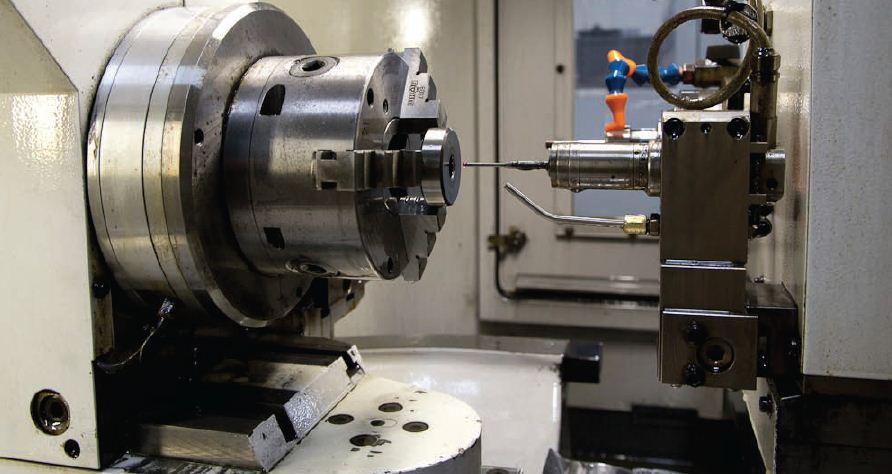

Subsequently, the company acquired a STUDER CT750 radius ID grinding machine for hard materials in 2011. The machine has a CNC-controlled B-axis with an automatic swiveling range from +60 degrees to -91 degrees. An oscillating grinding wheel enables it to produce an unlimited number of different radii up to 90 degrees. A modular turret with two grinding spindles provides great flexibility in the machining of individual parts as well as large-scale production. The machine handles small- to medium-size workpieces, with X- and Z-axis travels of 360 mm and 250 mm respectively, a grinding length of 100 mm, and a maximum ID grinding diameter of 80 mm.

“Part of what prompted us to look at the STUDER machine was to reduce cycle times and be more competitive on the pricing side,” Thomas said.

The machine’s CNC technology and structural rigidity ensure the production of a good grinding surface finish. Surface finish is critical in diemaking because it is the basis for final polishing. “The STUDER machine allows us to get a better surface finish faster than we could before, and reduces polishing by hand,” Thomas said, noting that excessive polishing can distort a part’s geometry.

The STUDER grinder also has in-process gaging capability that helps reduce cycle times. The probe measures the part during the rough grinding process and adjusts the operation to leave a minimum amount of material for finish grinding. Because finish grinding is slower than rough grinding, minimizing finishing passes reduces cycle times overall.

The machine’s CNC capabilities also boost part consistency. Previously, for example, reworking a wire die involved changing its contours via manual grinding. Now the shop can program an exact radius. “The STUDER machine allows us to produce a more consistent, uniform product,” Thomas said. “In the past when we ground the parts by hand, we might get a few tenths difference on the size. Now, we can sell a die today, and sell that same die a month from now, and it is exactly the same geometry. The customer knows the dies are identical.”

Thomas said the programming software has proven easy to use, both for employees who are familiar with computers and those who are not. However, he pointed out that the best results require a combination of computer savvy meshed with familiarity with the grinding process.

Thomas Wire Die soon found that the shop had enough work to keep the STUDER grinder going nonstop. As a result, the company recently added a second CT750 machine. “The machine’s increased efficiency has freed personnel to move to other areas,” Thomas said. “Where we might have had three people doing work, now we have one and a half. The other one and a half are working in other areas because of growth we are seeing in other products.”

In addition to increasing revenue, expanding and diversifying a company’s customer base can help moderate the effect of economic slowdowns. “Part of our thought process in how we grew our business was to try to expand into different markets,” Thomas said. “Working with customers in wire and cable, oil and gas, metal forming, metal stamping and wear parts helped us historically in that when there was a downturn in one area it didn’t affect everything.”

The depth of the most recent “Great Recession,” however, certainly had more impact than past slowdowns. Thomas Wire Die reluctantly performed the first layoffs in the company’s history. “That was a culture change,” Thomas said. “We realized we had to look more closely at cost control. New CNC grinders and wire EDM equipment have allowed us to increase our output. We are also looking at ways to increase the utilization of the equipment we have. We run a single shift now and we have a lot of capital equipment that sits idle two out of three shifts every day. We are looking at changing that, which will mean adding additional people.”

Today, Thomas Wire Die has 20 employees at its 17,000 sq ft. facility and handles between 150 and 200 accounts a year. The shop’s diverse skills enable it to participate in a variety of industry segments. For example, its cold-heading dies are used by suppliers to make fasteners for the aerospace industry. Similarly, the shop makes tooling that tier 1 and 2 suppliers use to deep draw and stamp automotive components.

The fastest growing market for wear resistant parts is the oil and gas industry. “There is more and more fracking activity in North America and worldwide, and it is driving a lot of that growth,” Thomas said. The shop makes carbide valve components up to 4” and 5” in diameter and 10” long as well as other parts such as nozzles and small wear rings. Some of the customers for the parts are international OEMs that use the components in assemblies that are shipped worldwide.

In the present era of struggling digital startups with alleged vast potential but questionable experience, Thomas Wire Die bases its growth on its prior successes and strengths, and applies that expertise to realize the potential of new and growing markets for its singular products and services.

About the Author

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Gema welcomes controller

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI