Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

FABTECH Chicago demonstrates further sophistication of technologies

Cobot programming simplified, ease of use improved in welding applications

- By Rob Colman

- November 6, 2023

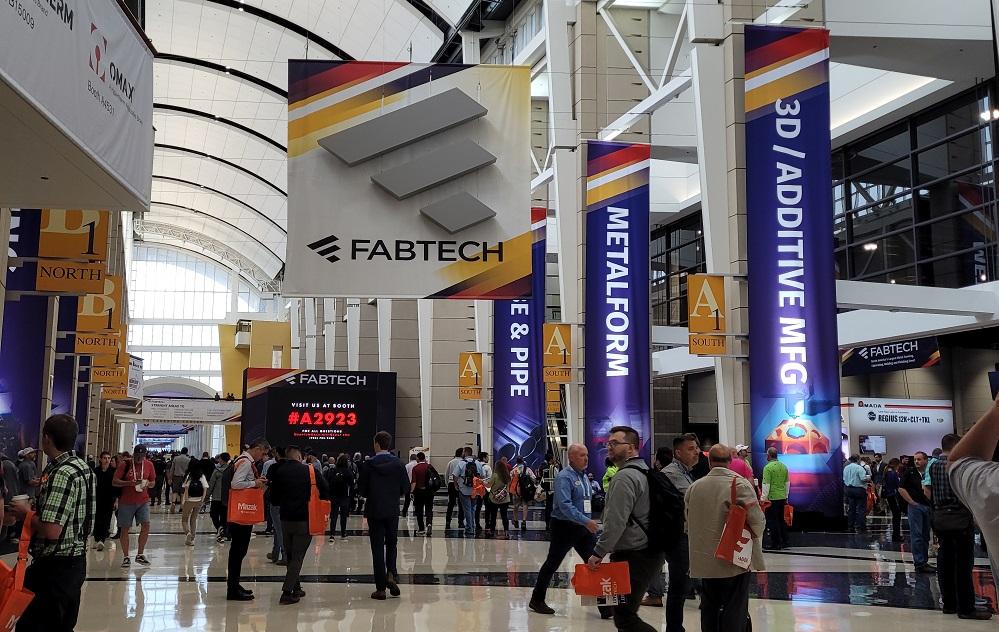

FABTECH Chicago was yet another whirlwind show. Over the course of four days, the Canadian Fabricating & Welding team had a chance to learn about many of the new machines and technologies on the show floor, all while catching up with industry colleagues.

Over the past 15 years, we’ve seen the introduction of fibre laser machines, Industry 4.0, and cobots, to name just a few examples of technology and ideas that made people stand up and notice. This year’s show was still full of revelations—TRUMPF’s coil-fed laser cutting table and DAVI’s fully electric plate roller come to mind—but most were less visually obvious and more of an exercise in fine-tuning.

The software connected to many technologies has become more sophisticated, making it easier to operate a variety of welding machines and cobots. Whatever these machines could do before, they now can do it with simpler programming processes or they can be dialled in using a more intuitive interface. Technology for both welding and fabricating machines that allows operators different levels of machine access depending on their role on the shop floor also was on display.

Many booths provided automation demonstrations that included the use of robots or cobots. AMADA had an automated blank-to-bend setup, using automated guided vehicles (what the company calls its Autonomous Mobile Transport Engineering System, AMTES) to move parts from cutting to bending to the end of the production line. Having such a setup on the show floor made a real statement that all technology is in play to make systems like this possible.

And speaking to a number of attendees, the question was not, “Will we invest in automation?” but “What level makes sense right now?” Many shop owners I spoke to were considering the value of cobots for welding and finishing operations. One fabricator was considering the next steps for his growing production needs and whether a blank-to-bend unmanned setup could work effectively given his part mix. Everyone needs to accomplish more with fewer skilled employees. It’s simply a matter of where the investment makes the most sense.

We will have a full show wrap-up in our November issue. In the meantime, check out our social media channels to see photo and video highlights of the show floor.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

Rob Colman

1154 Warden Avenue

Toronto, M1R 0A1 Canada

905-235-0471

Robert Colman has worked as a writer and editor for more than 25 years, covering the needs of a variety of trades. He has been dedicated to the metalworking industry for the past 13 years, serving as editor for Metalworking Production & Purchasing (MP&P) and, since January 2016, the editor of Canadian Fabricating & Welding. He graduated with a B.A. degree from McGill University and a Master’s degree from UBC.

- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Gema welcomes controller

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI