Marketing Communications Specialist

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

All standards are not created equal

Understand the differences among Canadian, U.S., and European standards to better understand how to start work in Canada

- By Rhea Gill

- May 22, 2019

With the pace of change in the world today, it can be hard to keep track of industry standards, which are constantly in flux. This article will explain why Canadian welding standards are highly valued nationally and internationally.

Take John, for example. John has lived and worked in Minnesota his entire life but recently decided that he wanted to move to Manitoba in search of better opportunities and financial incentives. Having been a welder for about 10 years, he believes that his skills can be transferred to Canada and he can begin working and earning right away.

Unfortunately for him, this isn’t the case. Since every country follows its own set of standards, it is important to first research (a) the rules of the country that you are moving to and (b) what criteria you, as a welder, have to meet to serve that market. Understanding global welding requirements and how they differ from Canada’s is critical to success in the sector and something that all immigrants must consider before entering the workplace.

To understand the objectives of welding standards, we first have to understand the key drivers of structural welding standards in Canada, the U.S., and Europe. It is essential to identify fundamental differences to confirm where substitutions are permitted and where they are not. To help someone like John, we will outline the significant similarities and differences.

When CWB certification representatives chat with welders and companies, one of the first questions they have to answer is, “Who says that I have to use this standard? Why do I have to be CWB certified?” In this case, it’s imperative to understand that reference to welding standards is often indirect. The requirement to follow a welding standard is driven by various sources, including a national or local building code, safety regulations, or owner requirements.

Although John doesn’t need a thorough knowledge of the building codes in Canada, having an understanding of the code differences will greatly benefit his progression. Welders moving to Canada need to know that we have a National Building Code of Canada (NBCC), developed by the National Research Council Canada, and each province and territory adopts a version of the NBCC through its legislation. However, structural steel requirements are the same for all provinces and territories. If a trade is within the parameters of these building codes, the fundamentals for welded design and fabrication are essentially the same.

A key difference in the U.S. is that the International Building Code (IBC) – the U.S.-model building code – is adopted at a state or jurisdictional level as they choose to adopt it. Therefore, not all jurisdictions follow the IBC, or they adopt it with various modifications. In the EU, the Construction Products Regulation (CPR) is very much like the NBCC; it is mandatory the way that it is written and is implemented without any alterations in any EU country that has signed on to be in that economic community.

So, if you are moving from the EU, is there a need to qualify in Canada? What are the significant differences in the requirements, because they all seem similar? The short answer is that, at a high level, most countries approach welding in the same manner. However, as the saying goes, the devil is in the details.

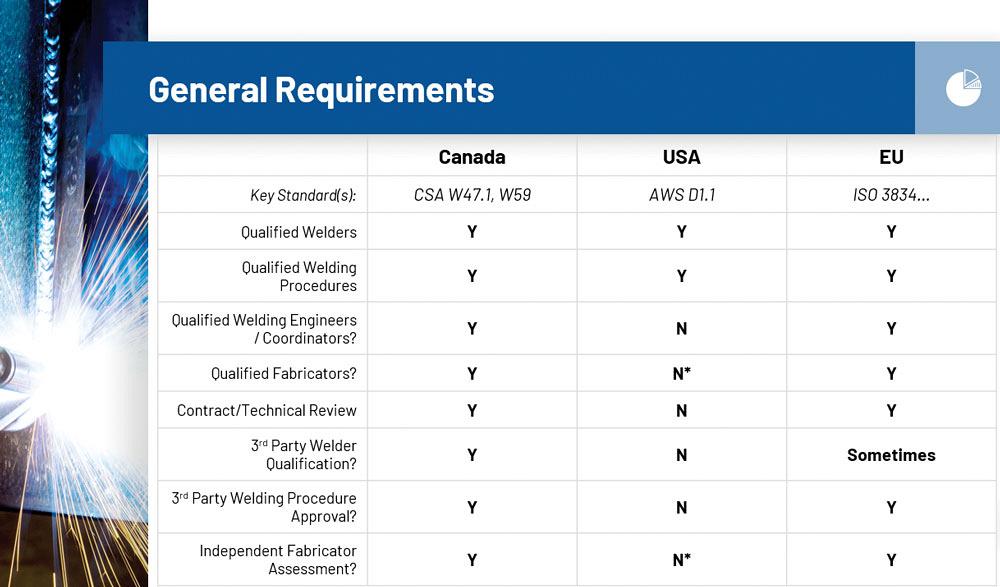

Welders in all countries must be skilled and qualified/certified in the welding process(es) they use and have to follow approved/accepted welding procedures. However, when it comes to employing welding engineers and supervisors, only Canada and the EU require them to be licensed or certified in those roles. The U.S. makes no specific reference to these roles, but that doesn’t necessarily mean they don’t exist. It merely means that it is not driven by the standard itself. The concept of qualified fabricators and fabrication as an entity exists only in the Canadian and EU system. Although the AWS offers a program in the U.S. to certify fabricators, it is not a mandatory requirement. See the charts for a visual representation of the critical differences in the three economies.

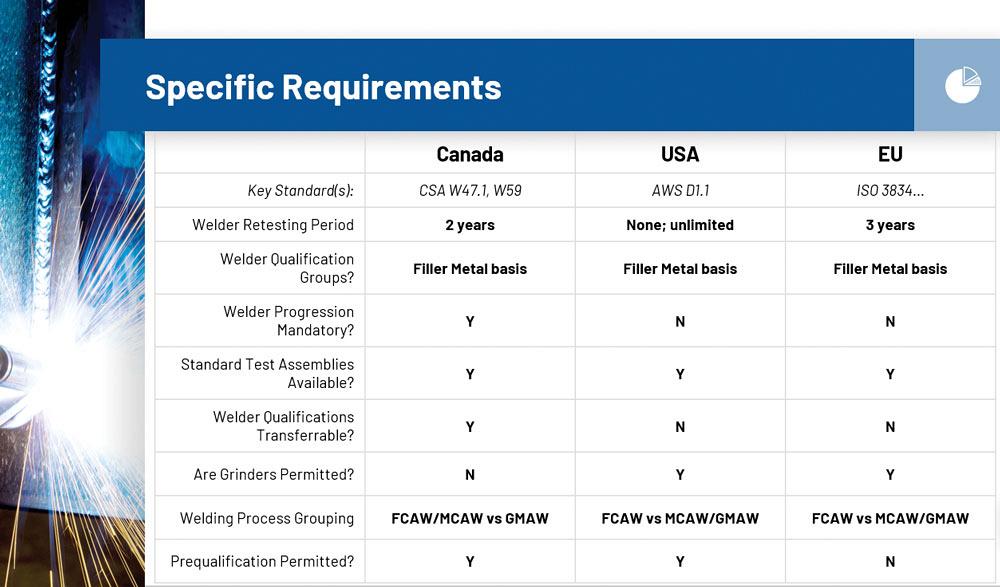

For John to know what he’ll need once he applies for a job as a welder, he must understand the testing specificities. In the U.S., once you have been qualified as a welder, you remain certified as long as you choose to work as a welder. However, in Canada, welders are retested every two years to ensure that their skills are up-to-date and they remain competent in the workplace. In the EU countries, this period is every three years. John has been through training sessions in Minnesota to prove that his qualification is valid, but he doesn’t need to be retested. This is one of the major differences that John must now contend with and be accountable for should he choose to pursue a welding career in Manitoba.

One major similarity that all three regions share is the ability to qualify a welder in what is known as the standard test assembly. This is a configuration that is not driven by what the company is doing but rather is based on a standard test that all companies can use. Approximately 95 per cent of Canadian welders have completed their qualifications on a standard test assembly. This means that they can transfer their qualification throughout Canada provided that they’ve completed the standard test assembly.

The Netherlands has embraced the Canadian standard test assembly because it is a highly efficient way to qualify welders and provides employers with great information about their skills. It is a true credit to the Canadian system that a longstanding European country has adopted our testing style. This system ensures that a welder can transfer that qualification as he or she moves from company to company. It allows organizations to hire welders and get them to work right away without expensive requalification costs. Once John has gone through a standard test assembly process, he will become part of this system, making it easier for him after he has completed his qualification in Canada.

Another major question that John, a U.S. citizen, should ask is if he must follow CSA guidelines instead of ISO or AWS. Are substitutions allowed? The answer is that Canadian welding standards do not permit any substitutions. Currently the U.S. allows substitutions through a very specific route and with the approval of the appropriate jurisdiction. In the EU, no allowances are permitted for welding certification programs. The CWB Group has worked hard over the years to gain acceptance of our program. Currently over 50 U.S. jurisdictions recognize CWB certification as meeting the requirements of their building code. However, the same allowances do not exist in the Canadian standard.

It is easy to get confused in the sea of information available to newcomers, and the different standardized testing can be extremely daunting. The CWB Group is here to serve the needs of welders and future welders by providing them with the resources necessary to thrive. If you are looking to convert your skills and qualifications to the Canadian standard, please do not hesitate to reach us at 1-800-844-6790 or email us at info@cwbgroup.org.

Rhea Gill is marketing communications specialist at CWB Group. This article was written with the support of Craig Martin, vice-president, certification, CWB Group.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Hypertherm Associates partners with Rapyuta Robotics

Protected and productive: welding helmet tech

HGG Profiling Equipment BV names Western Canada area sales manager

Compact weld camera monitors TIG, plasma processes

- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada