- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Robotic bending cell features built-in adaptive bending system

- April 3, 2024

- Product Release

- Automation and Software

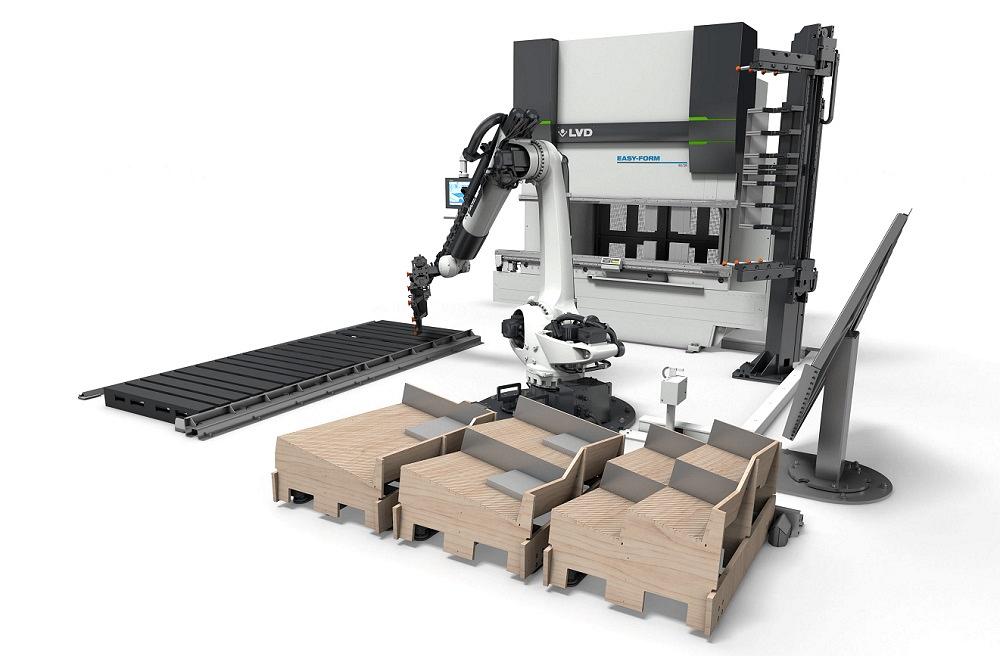

LVD Co. nv has introduced the Easy-Cell 80/25 robotic bending cell for automated bending of a variety of parts. It combines an Easy-Form 80-ton press brake with a KUKA industrial robot to handle parts from 100 by 100 mm to 1,600 x 1,200 mm and weighing up to 25 kg.

The press brake features a 2,500-mm bend length, 5-axis backgauge, and 2,500-mm crowning table. The robot uses a swivel function to help optimize regripping, and the multiple robot grippers can be changed to suit the job.

The cell is equipped with an Easy-Form laser that uses adaptive in-process control over the bend angle. The system compensates for material variations such as sheet thickness, strain hardening, and grain direction. Scanners continuously measure the bend angle and transmit the information in real time to the CNC for immediate adjustment of the punch position to achieve the correct angle.

CADMAN-SIM software automatically generates bending and robot programs and defines all gripper positions.

LVD | www.lvdgroup.com

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Gema welcomes controller

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI