- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

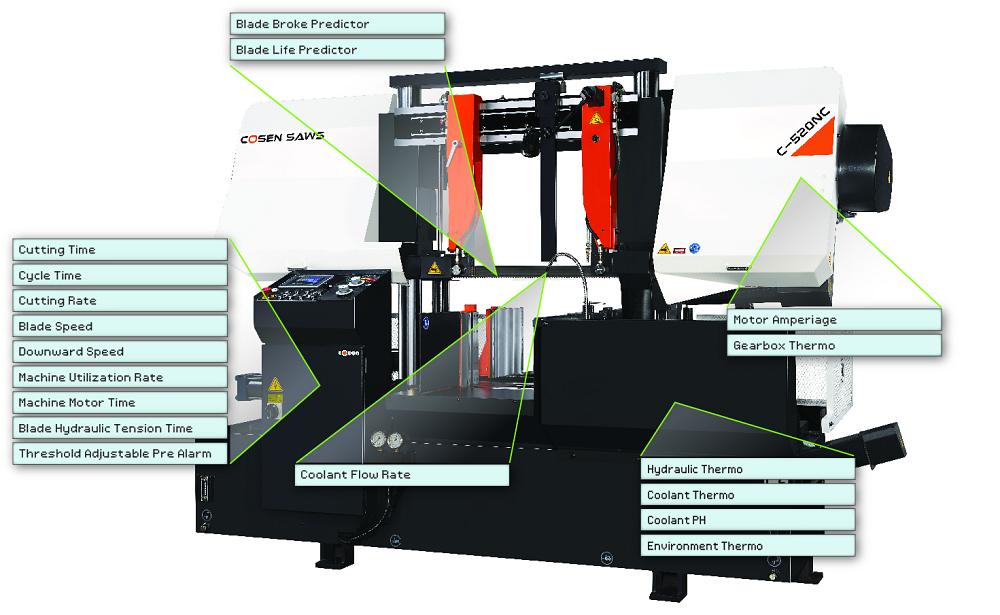

Cosen Saws launches a cloud-based machine monitoring technology

The technology is intuitive and user customizable.

- October 5, 2015

- Product Release

- Fabricating

Cosen Saws has introduced MechaLogix Cosen Predictive Computing, a cloud-based system. This new system monitors the performance of a blade and can accurately forecast the number of remaining cutting hours left before a saw blade dulls and is no longer cutting with precision or a complete breakage.

MechaLogix also gives you real time performance data and can report issues like excessive vibration, overheating and changes in fluid line pressure. The root cause of an issue is reported in real time which equates to minimal down time and more efficient operations.

“Know the unknown—now you can,” said Joshua Sun, Business Development Manager for Cosen Saws. “This completely changes the game for cloud based machine monitoring systems. “Our customers have told us how important it is for them to minimize waste and scrap. Having a blade fail in the middle of a cut is one of the primary causes of waste and scrap and it negatively impact profits.”

“With our technology, both operators and management will know the remaining useful life on a band saw blade” Mr. Sun added. “Gone are the days of tracking machine hours and accumulated cutting area. Now you have advance knowledge of the days and hours before a replacement saw blade is required. That’s what MechaLogix Cosen Predictive Computing does.”

The technology is intuitive and user customizable. Adjustable alert notification settings work seamlessly with the mobile app. “We have been delighted with the enthusiastic response from our customers who have partnered with us during the course of the program”, said Mr. Sun.

The comprehensive program includes:

Blade Life Assessment – Monitoring and alert notification of a saw blade’s remaining useful life. The technology will provide advance notice of required saw blade replacement.

Increased Machine Efficiency & Machine Life – Our technology provides real time analysis of individual components and overall machine health status. It can send notification of abnormal conditions from motors and bearings. It also alerts on frequent consumable items like hydraulic and cutting fluid.

Increased Operational Efficiency – Our technology can provide production reports to aid in identifying best practices and training needs. Our advanced monitoring and notification system alerts the operation when machine maintenance is needed which aids efficiency in the scheduling of planned events.

For more information, go to www.MechaLogix.com

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

CWB Group launches full-cycle assessment and training program

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI